What’s the Best Gummy Making Machine: a Complete Guide

Have you ever wondered how those delicious gummy candies are made? They are actually made by a gummy making machine.

If you work in the food or pharmaceutical industry, you should know how important this machine is for a gummy production line.

But how do we pick the best among the mixed bag of gummy making machines?

Don't worry, we're here to help! Our guide will provide you with all the information you need before buying a gummy making machine. From presenting our selection of the top 2 most popular machine models, to the different types of such machines, and finally listing the considerations for choosing the best gummy machine.

Top 2 Picks for Best Gummy Making Machines in 2024

What should a good gummy production machine look like?

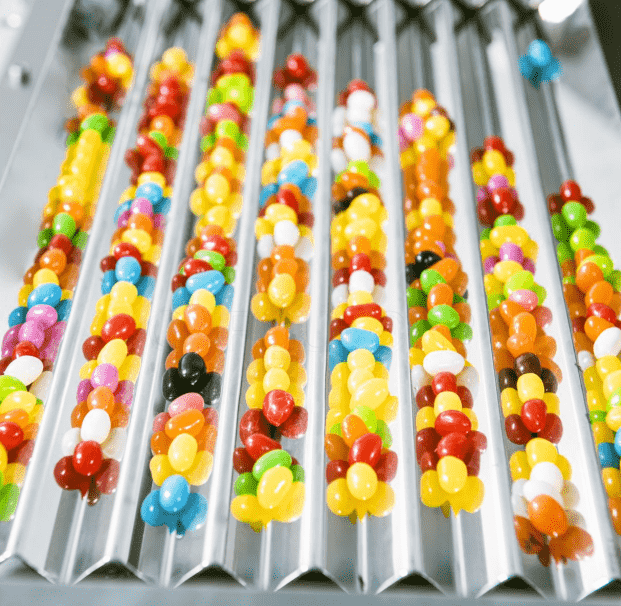

A good gummy making machine should ensure that the quality of the gummy produced in different batches is consistent in terms of weight, shape, texture and color. It should also produce gummy candies as quickly as you require, while minimizing waste and downtime.

Below are our recommendations for the best gummy bear making machine in 2024.

1. CTG-S80 Semi-automatic Gummy Bear Making Machine

Model CTG-S80 gummy production line is an advanced continuous machine for various types of gel-based gummy candies. The equipment is compact, stable and user-friendly. It is an ideal machine for both cost saving and high quality gummy candy production.

Key Features

- The CTG-S80 produces consistent quality gummy bears. It guarantees consistent size and shape of gummies from batch to batch.

- The machine's hygienic, starch-free process is ideal for use in the pharmaceutical field.

- The machine facilitates the addition of various nutrients to the gummies.

- With sturdy and flexible casters

- CTG-S80 is easy to maintain and clean

- Constructed of food-grade stainless steel

2. GD 150Q Automatic Gummy Manufacturing Equipment

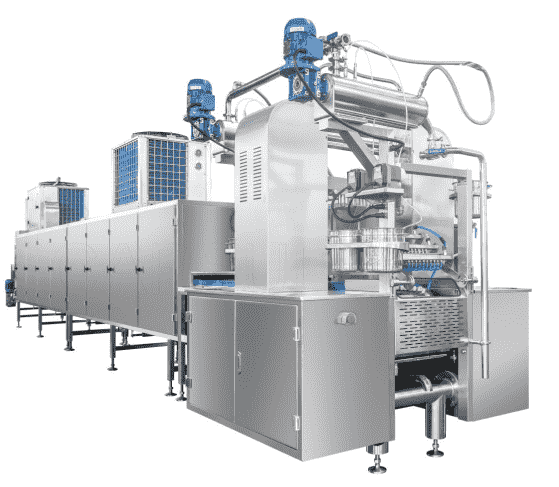

The GD 150Q gummy making machine is a fully automated production line with a built-in cooling unit. It utilizes a continuous production process to increase manufacturing speed while maintaining strict quality control. The machine produces high quality and smooth gummy candies in a hygienic environment. It is the best machine for large scale candy production.

Key Features

- The GD 150Q has a capacity of up to 150 kg/hour.

- Utilizes a PLC control system

- Equipped with human-machine interactive touch screen, it is easy for the operator to control the machine and modify the parameter settings.

- This machine can be easily adapted to various molds to produce different shapes of gummy candies.

What Are Common Types of Gummy Making Machines?

Like many other production equipment, there are different types of gummy making machines. Most commonly, they are categorized by the degree of automation, i.e., fully automatic gummy candy making machines and semi-automatic gummy candy making machines.

Automatic Gummy Making Machine

From precisely measuring and mixing the ingredients, to placing the mixture into molds, cooling and drying the fondant, and even to the final packaging, the fully automated gummy maker handles the entire production process.

It minimizes manual intervention while maximizing efficiency and output. As a result, the automatic gummy production line is ideal for large-scale enterprises that need high output and consistent gummy quality.

Pros

- A fully automatic gummy bear machines can produce large quantities of gummies in less time than manual or semi-automatic ones.

- It requires fewer operators, thus reducing overall production costs.

- It ensures that the weight, shape and texture of each piece of gummy is consistent, which minimizes batch-to-batch variation.

- The automated process reduces direct contact with ingredients, making the gummy bear production process more hygienic.

Cons

- Automatic gummy production equipment is usually much more expensive than semi-automatic ones.

- More specialized knowledge is required for regular maintenance and troubleshooting

- Operators have less direct control over the production process and may require additional quality control measures.

Semi-automatic Gummy Making Machine

Semi-automatic gummy making machines can automate some of the key steps, such as heating, mixing and depositing the gummy mixture, but still require manual labor to perform tasks such as loading the molds and unloading the finished gummies. If you are a small business or home producer on a budget, choosing a semi-automatic fudge maker is not a bad idea.

Pros

- Semi-automatic gummy bear machines are often more cost-effective than fully-automatic ones

- Operators have more direct control over the production process, so they can freely adjust gummy recipes or troubleshoot the machine.

- Less complex semi-automatic gummy dispensers typically require less maintenance than fully automated models.

Cons

- Semi-automatic gummy making machines usually produce at a lower speed and throughput than fully automatic options.

- Manual operation may result in inconsistent weight, shape and texture of gummy candies from batch to batch, which probably affects the quality of the final products.

- More people are required to operate the machine, which may increase the overall labor cost.

How Can I Find the Best Gummy Manufacturing Equipment?

Everyone wants to find the best gummy manufacturing equipment, but we all know it's not an easy task, especially for beginners. However, once you understand your production needs and carefully evaluate the available options, finding the best gummy candy maker will be a piece of cake.

Here are some key questions you need to ask yourself and important factors to consider when looking for the right gummy bear machine.

- Determine your production goals first

How many gummies will you produce? Your answer will determine the capacity of the gummy production equipment you need. Whether you are producing small batches or large production lines, matching the capacity of your machine to your production goals is the key to improving efficiency.

- Imagine your perfect gummy candy

What shape and size do you want your gummies to be? You'll want to make sure that the gummy making machine you choose can efficiently handle the gummy shape you have in mind. Whether your ideal is a classic bear shape or an oddly shaped gummy, it's important to choose a machine that can mold your gummies perfectly.

- Always take your budget into consideration

It's tempting to go for the most advanced and powerful machine model. But, Buying one that meets your production needs and is within your budget may be more wise. You don't want to go broke by purchasing a gummy making machine, do you?

- Who will operate the machine also matters

If you are going to let an inexperienced novice operate your gummy making machine, then it is best to choose a model that is easy to operate at first. But, if you have an experienced expert to operate the machine, then you can choose a model with more complex features.

For more inspiration on picking the best gummy making machine, you can check out the following blogs

- 6 Questions to Answer Before Purchasing a Gummy Bear Machine

- Top 6 Gummy Candy Machine Manufacturers in the World 2024

- A Quick Guide to Different Types of Gummies

Leave your comment

Also Offers

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche