Introduction

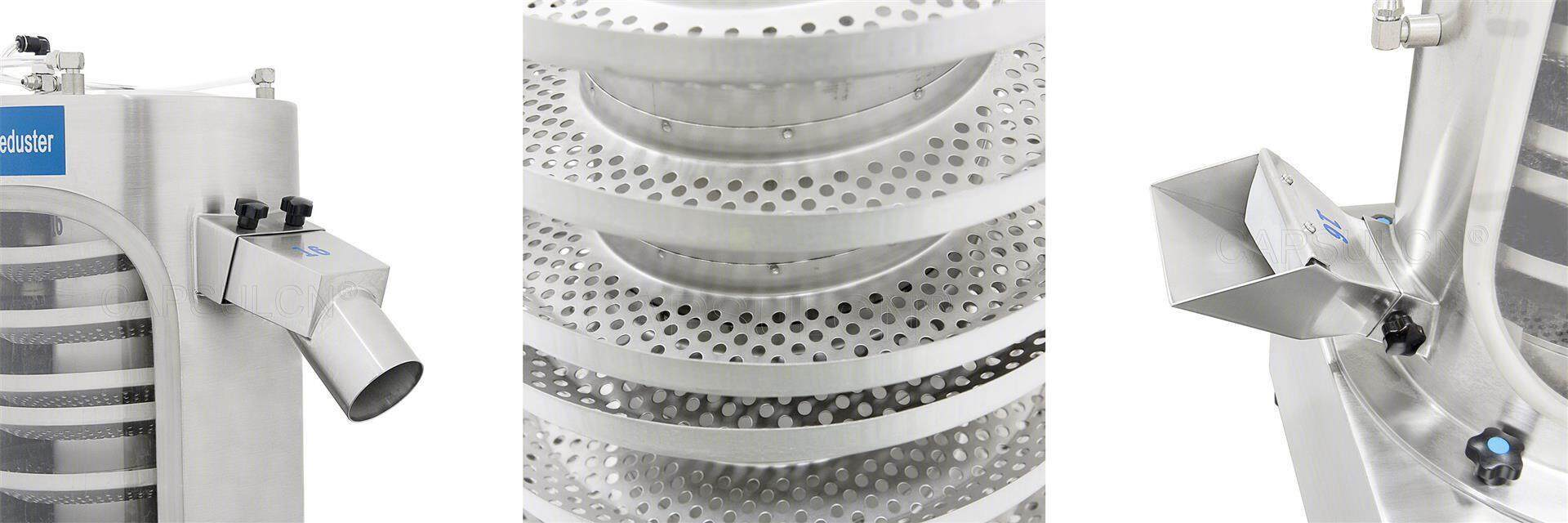

The SZS-750 Uphill Tablet De-duster is a special equipment to wipe out burr and dust of tablet whilst going up way. It can be connected with tablet press and metal detection systems.

The function of the machine is tablet dust removing, lifting and sieving.

316L stainless steel are used for all metal parts contacting tablets which is according to GMP standard.

It is widely used in the industries such as chemical, food. etc.

Specifications

| Model | SZS-750 |

|---|---|

| Capacity(pcs/hour) | 800,000pcs/h(depending on dia 6mm) |

| Tablet diameter | dia 3mm-25mm |

| Inlet height | 825-1005mm |

| Outlet height | 1230-1410mm |

| Dedusting distance | 7.5m |

| Compressed air | 0.1m3/h (0.05MPa) |

| Vacuum cleaning | 2.7m3/h (-0.1MPa) |

| Power supply | 110V 60Hz / 220V 50Hz 0.1kw |

| Outline dimensions | 550*550*(1365-1545)mm |

| Machine weight | 80kgs |

Remarks

- Height of outlet is easy to adjust;

- Fast-joint system makes it much safer and quicker to disassembly and assembly;

- 360° circle adjustment of inlet and outlet to make production more convenient and save factory room;

- With outstanding efficiency, it is suitable for mass production of Φ3-Φ25mm all-kind-shape tablet;

- Parts in contact with material are all made of 316L stainless steel. No blind spot makes it easy to clean. Meet cGMP demands;

- New design motor driver to ensure the machine runs more stably with lower noise;

review(s)

Deduster

The dust removal function is very powerful. Ten good machines

From: Davis | Date: 3/1/2021 3:49 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche