Video

Introduction

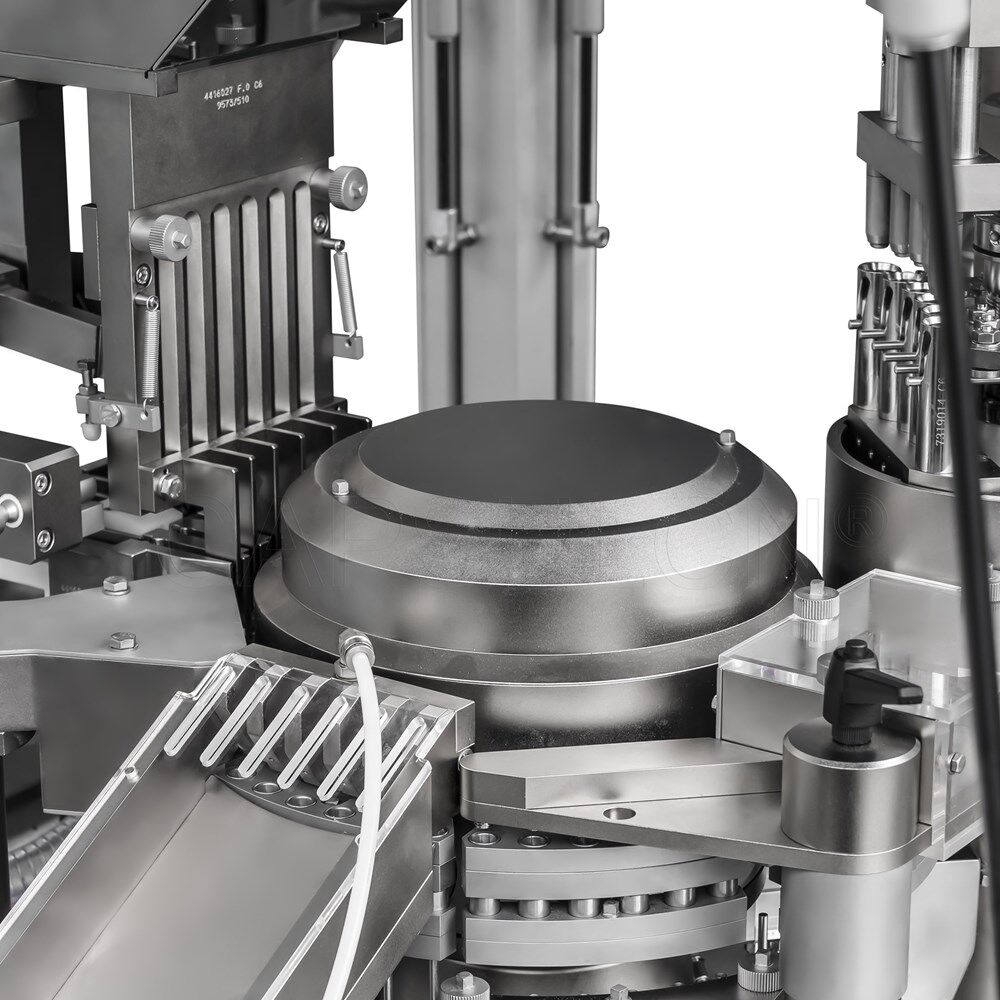

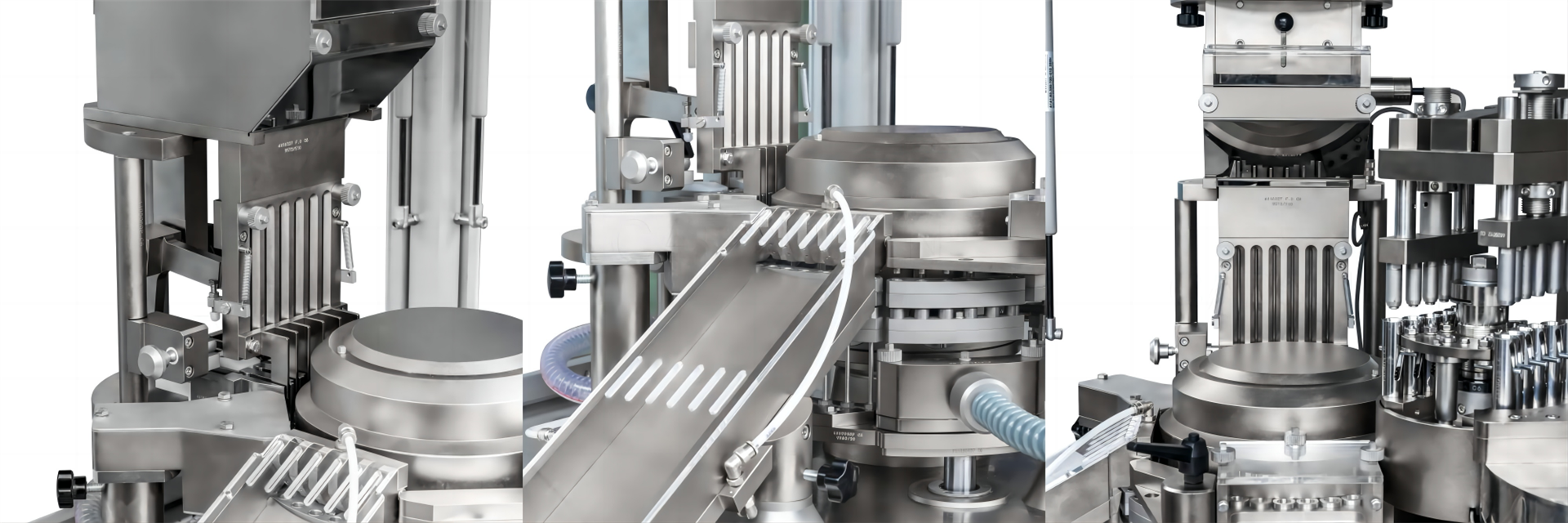

CZ-40 is a fully automatic capsule filling machine. It is mainly used for filling capsules of various specifications in the pharmaceutical industry, covering the packaging of various types of drugs such as powders, pills, and microtablets. The machine has an intermittent motion design and can quickly and accurately complete the assembly, filling, and locking of the capsule body and capsule cap. Its main structure includes key components such as workbench, polishing barrel, sorting device, inlet and outlet, dust collection system, etc., all of which meet the requirements of GMP clean workshops.

Specifications

| Machine model | CZ-40 |

|---|---|

| Max capacity | Powder:39000-40000Grain/h Pellet: 39000-40000Grain/h Tablet: 29250-30000Grain/h Liquid: 35000-36000Grain/h |

| Suit for capsule size | 000#-5# |

| Maximum Speed | 111r/min |

| Power | 8kw |

| Rated Voltage | 380V/50Hz |

| Minimum dimensions | 1210*920*1796mm |

| Weight | 1000KG |

Feature

- Flexibility and diversity: The CZ-40 capsule filling machine supports the filling of various dosage forms such as powders, pills, microtablets, and even liquids, and can meet different material characteristics and dosage requirements.

- Reduce tailings: By configuring accessories such as powder-saving troughs, powder-saving buckets, and powder-saving trays, the loss of materials during the filling process is effectively reduced, which has obvious economic benefits, especially for expensive or scarce raw materials.

- Automation and intelligence: The equipment has an intelligent alarm function, which can monitor the status of the capsule in real time and provide immediate feedback when an abnormality occurs, ensuring the safety and accuracy of the production process. At the same time, it has multi-level operation authority management and various troubleshooting functions.

- High-efficiency production capacity: Whether it is a powder or pill filling system, the maximum production capacity of the CZ-40 can reach 40,000 tablets/hour, and it can also achieve corresponding high-efficiency production capacity for tablet filling under specific conditions.

- Quality assurance: By using high-quality materials and finely processed core components, such as stainless steel powder barrels, powder trough covers, rotating powder disks, etc., combined with high-precision measuring components, the consistency and high quality of the product are guaranteed.

- Expanded configuration: Provides a variety of optional functions, such as polishing machine, liquid filling system, vacuum feeding machine, etc., to adapt to the individual needs and process flows of different users.

- Compliance and safety: The design of CZ-40 fully considers production safety and environmental protection, complies with a number of international and domestic regulations and standards, and ensures long-term stable operation of the equipment through rigorous electrical design and component selection.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Full-Automatic Capsule Filling Machine SFK-3000

Fully-Automatic Capsule Filling Machine SFK-700

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche