Video

Introduction

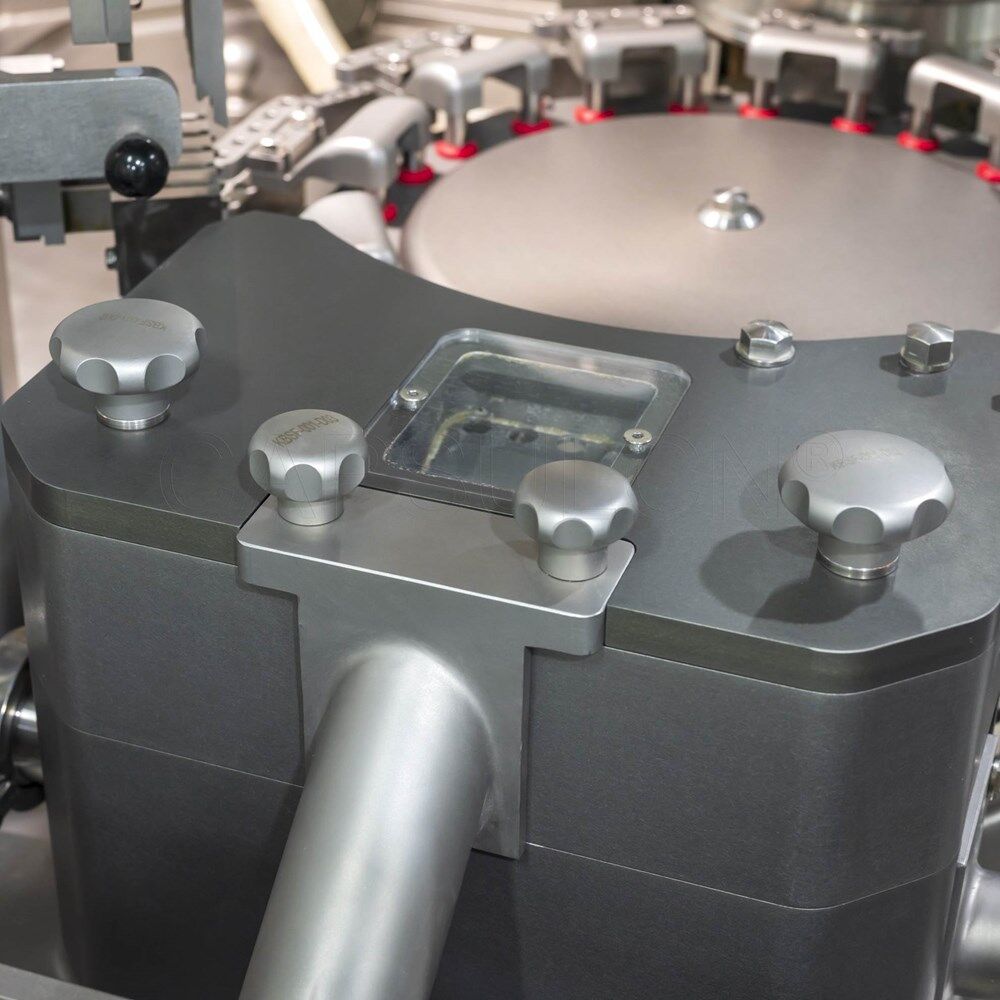

The SKF 703 platform offers all features and functionalities from the SKF 700. It offers a washable containment concept (WIP) ensuring highest protection class for operators, up to OEB 4product requirements (1.0-10.0 µg/m³). The SKF 703 is able to produce small batches for research and development or clinical trial supplies.

Washable high containment concept with reduced water requirement up to OEB4

Dust and water tight machine table through tabletop design and air-purge seals.

SFK-703 full automatic hard shell capsule filling machine adopts an international advanced design concept. Through the clearance operation, the full automatic hard capsule filling machine is completed by the pressure type of the high precision metering disc filling rod.

The design of the equipment parts is precise, the appearance is beautiful and practical, the operation is smooth, the mold can be replaced simply and quickly, and the capsule sorting ,Separating, filling, removing, locking, popping up, cleaning and many other processes can be completed automatically.

The equipment design is fully in line with the requirements of CGMP and FDA specification.

It is an intelligent device for pharmaceutical production, health care products and capsule production in food industry.

Specifications

| Machine model | SFK703 |

|---|---|

| Max capacity | 42000capsules/hour |

| Suit for capsule size | 00#-5# |

| No.of segment bores | 5 |

| Power | 3kw |

| Machine dimensions | 951*1551*2155mm |

Feature

- The equipment adopts the international high quality electrical components, so that the service life of the electrical parts of the equipment is longer and more stable.

- The equipment adopts monolithic platen design, each movement part is sealed to avoid the powder penetrating into or out of the room as much as possible to ensure the cleanliness of the workshop. All the motors that the equipment adopted are with low energy consumption, which fully achieves energy saving

- The equipment adopts German SIEMENS system, SIEMENS inverter drive, stepless speed regulation, SIEMENS PLC program control, stable operation, safe and reliable

- It offers a washable containment concept (WIP) ensuring highest protection class for operators, up to OEB 4 product requirements (1.0-10.0 µg/m³).

review(s)

GOOD

Very easy to use, you can get started right away, and friendly to new buyers

From: sevide | Date: 2/28/2021 10:54 PM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Full-Automatic Capsule Filling Machine SFK-3000

Fully-Automatic Capsule Filling Machine SFK-700

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche