2024 Rotary Tablet Press Buyer's Guide

Tablets are one of the most common formats for vitamins, minerals, and other dietary supplements. They are stable, easy to manufacture, and have a long shelf life. Plus, tablets are generally cheaper to produce than many other supplement forms. These factors make tablets a popular choice for a lot of supplement companies. The manufacturing process for tablets often involves the use of specialized equipment such as a rotary tablet press.

If you're thinking about adding tablets to your product lineup, this article will introduce you to everything you need to know before buying a rotary tablet press machine, including its definition, parts, working principle, types, and features to consider. Keep reading, and then you will know how to make a smarter purchasing decision.

What Is A Rotary Tablet Press Machine?

A rotary tablet press is a piece of specialized equipment widely used in industries like pharmaceuticals and nutraceuticals. This machine runs in a rotational manner to compress powders or granules into uniform tablets. Rotary tablet press machines are usually automated. Plus, the rotary motion enables them to mass-produce tablets at high rates.

While specific features can vary between models, almost all rotary tablet presses can ensure the consistent quality of the final product. Thanks to reliability and efficiency, rotary tablet press machines have been considered a necessity for many supplement and pharmaceutical companies.

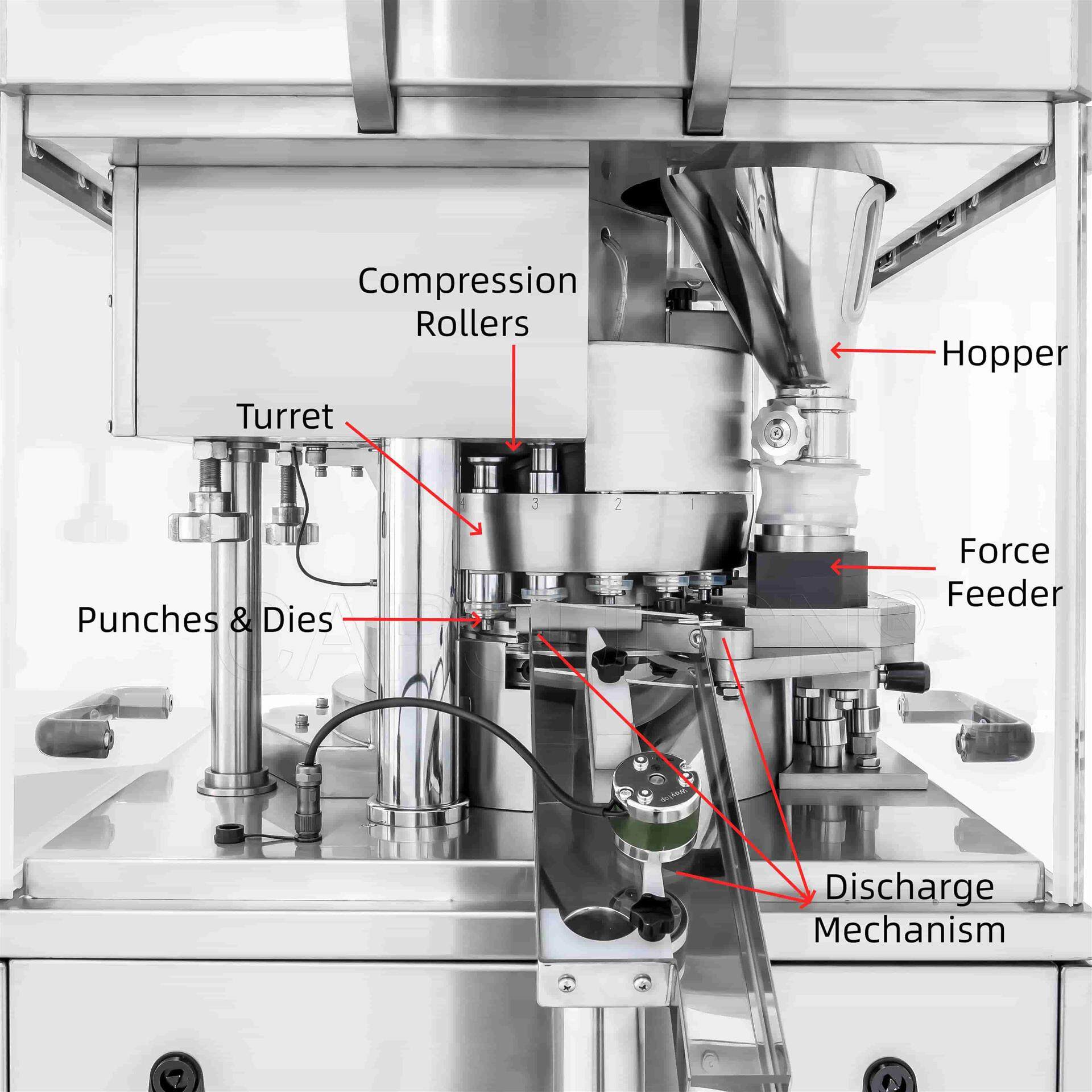

6 Main Parts of A Rotary Tablet Press

A rotary tablet press is filled with a host of parts. These components are assembled to power the tablet manufacturing process. If you're a first-time buyer of such a machine, having an understanding of the main parts of your tablet press is extremely helpful in visualizing how it functions.

1. Hopper

Sitting at the top of the machine, the hopper holds the powder for tablet production. It works by vibrating to guide the powder into the machine. This component can also control the flow, ensuring a stable material feeding.

2. Feeder System

The feeder system is the first stop after the powder enters the machine from the hopper. This system is responsible for delivering the powder into the die cavities where the tablets are formed. There are two types of feeder systems: a force feeder and a gravity feeder. The former uses paddle wheels to force the powder into the cavities. The latter utilizes gravity to fill cavities with the powder.

3. Punches and Dies

Punches and dies are the most important parts of a rotary tablet press machine. The punches come in pairs (upper and lower). The punch tips can be customized to create tablets of different shapes and sizes. The dies have cavities for holding the powder. The upper and lower punches move against each other in the cavities to compress the powder into tablets.

4. Turret

The turret is the rotating part of the rotary tablet press machine. It holds the punches and dies, ensuring their alignment. The whole tablet manufacturing process is complete as the turret moves. This component can be designed for quick changeovers between different tableting needs.

5. Compression Rolls

Compression rolls in a rotary tablet press consist of precompression rolls and main compression rolls. The former performs an initial compression to remove air from the powder in the die cavities. The latter applies the main pressure to compact the powder into a solid tablet. These compression rolls can be adjusted before exerting forces on the powder to optimize the quality of the tablets.

6. Tablet Discharge Mechanism

This mechanism includes an ejection cam, a take-off blade, and a discharge chute. The ejection cam forces the lower punches to go up to push the formed tablets out of the die cavities. Then, the take-off blade guides the tablets to the discharge chute.

Working Principle of A Rotary Tablet Press

With the knowledge of the main parts of a rotary tablet press, it's easier to understand how this machine works. Here, we break down the workings of a rotary tablet press into four stages.

Stage 1: Filling

The tablet-making process starts with the filling stage. Here, you load the powder into the hopper. The powder then flows into the feeder system, which evenly distributes the powder into each die cavity.

Stage 2: Metering

Next is the metering stage. This step is all about precision: the machine measures the exact amount of powder needed for each tablet. The excess is scraped off. This ensures the consistency of the final product.

Stage 3: Compression

This stage is divided into two parts:

1. Precompression: First, the upper punch comes down while the lower punch goes up. Both punches apply moderate pressure onto the powder in the cavity to form a slug. This is to remove any air from the powder.

2. Main compression: Then, the main compression rollers press down the upper punch and push up the lower punch. Both punches apply a higher pressure to further compact the slug. The dwell time of punches can be adjusted depending on the characteristics of the powder.

Stage 4: Ejection

The last stage is ejection. Here, the lower punch rises to push the finished tablet out of the die cavity. Some rotary tablet presses can even reject defective tablets at this stage, ensuring the quality of the whole batch.

Different Types of Rotary Tablet Press Machines

Rotary tablet presses are available in many variations.

- Based on the number of formulation layers:

|

Feature |

Single-Layer Rotary Tablet Press |

Bi-Layer Rotary Tablet Press |

|

Design |

Can be single-sided or double-sided |

Single machine designed specifically for bi-layer tablets |

|

Formulation |

Produces tablets with a single formulation |

Produces tablets with two distinct layers, each with different compositions |

|

Filling Process |

Fill the single formulation into the die cavities |

Fill the cavities with two different formulations, one for each layer |

|

Compression Process |

Compress in one step to form a single-layer tablet |

Compress one formulation at a time to form a bi-layer tablet |

- Based on production capacity:

|

Feature |

Single-Sided Rotary Tablet Press |

Double-Sided Rotary Tablet Press |

|

Production Scale |

Suitable for small to medium-scale production |

Designed for higher output requirements |

|

Filling |

Powders are filled into die cavities on one side of the machine |

Powders are filled into die cavities on both sides of the machine at the same time |

|

Compression Process |

Upper and lower punches compress the powder inside the cavities on one side of the machine |

Compression occurs on both sides of the machine |

|

Ejection |

Lower punches push the formed tablets out of the cavities once compression is complete |

Formed tablets are ejected from die cavities on both sides of the machine at the same time |

Rotary Tablet Press vs. Single Punch Tablet Press

Aside from rotary tablet presses, there is another choice of tablet compression machine called single-punch tablet presses. Let's take a look at the differences between these two types of tablet presses.

|

Feature/Characteristic |

Single-Punch Tablet Press |

Rotary Tablet Press |

|

|

|

|

|

Ideal For |

Small-scale production, research and development (R&D), and pharmacy use. Suitable for working environments with limited space. |

Large-scale production, commonly used in the pharmaceutical and nutraceutical sectors. |

|

Basic Description |

Basic type with a single station for tablet production. Produces one tablet at a time. |

Multi-station machine with continuous rotation. Capable of producing a large number of tablets simultaneously. |

|

Construction |

Typically comes in a tabletop style. Simple construction with an upper punch, a lower punch, and a die. |

Complex design with multiple tooling stations arranged in a circular turret. |

|

Working Principle |

Uses one station of tooling to compress powder into a tablet. Steps include manual loading, compression, and ejection of tablets. |

Operates with multiple tooling stations on a rotating turret. Steps include filling, metering, precompression, main compression, and ejection of tablets. |

|

Ease of Use |

Easy to operate with minimal training. Can be hand-operated or semi-automatic. |

Requires more training due to complex design. Usually comes in an automated system. |

|

Production Capacity |

Lower output, suitable for small batches or custom formulations. |

Higher output, capable of producing over 200,000 tablets per hour. |

|

Tablet Uniformity |

Tablets may have slight variations in weight and hardness. |

Produces tablets with consistent weight, hardness, and size due to advanced technologies. |

|

Compression Force |

Moderate compression force, suitable for basic formulations. |

Greater compression force, capable of handling a wide variety of formulations. |

|

Changeover Time |

Not applicable or very simple due to a single tooling station. |

Quick and easy changeover, allowing for rapid switching between different tablet formats or formulations. |

|

Integration Capability |

Limited integration capabilities, often used as standalone units. |

Can be integrated into automated production lines, compatible with other equipment like coating machines and blister packaging equipment. |

|

Cost |

More affordable, lower initial investment, and maintenance costs. Ideal for beginners. |

More expensive, higher initial investment but offers greater efficiency and production capabilities. |

10 Questions to Ask Before Buying a Rotary Tablet Press

When you shop for a rotary tablet press, it's important to gather as much information as you can about the machine. If you're thinking about financing the purchase, here are questions that will guide you to the right tablet press machine.

1. What is the production capacity of the machine? Understanding the output allows you to determine if the machine can meet your production needs.

2. Can the machine handle different types of materials? A machine that is flexible enough can be beneficial if you have different production plans.

3. What are the key features of the machine? Knowing the features helps you understand the capabilities and limitations of the machine.

4. What is the cost of the machine? Knowing the pricing allows you to budget accordingly. Plus, you can compare prices with other machines.

5. What is the maintenance schedule of the machine? Knowing when and how to maintain the machine can help keep it in good shape.

6. Does the machine require training to operate? Essential training ensures the safe and efficient operation of the machine.

7. What technical support is available after purchase? Technical support can help you troubleshoot and maintain the machine in a more efficient way

8. Are there any additional tools included in the machine? Knowing the additional accessories helps you prepare for setup and operation.

9. Does the machine come with a warranty? A warranty can provide you with coverage when the machine experiences any issues.

10. What is the lead time for delivery and installation? Knowing the lead time helps you plan your production schedule accordingly.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche

.jpg)