2025 3-Side Seal Packaging Machine Buying Guide

Have you ever noticed the packaging of your favorite snack or vitamin tablets? It's often a bag or pouch sealed on three sides, locking in freshness and convenience. More brands love this kind of packaging as it offers a cost-effective way to package their products. This makes 3-side seal packaging machines become must-have equipment for many manufacturers.

Interested in this machine as well? Then you shouldn't miss out on our comprehensive guide! In it, we'll look at the basics of 3-side seal packaging machines and what to consider when shopping for one. Whether you're a small startup or a major producer, getting a solid grasp on this machine will be key to elevating your business in 2025.

What is 3-Side Seal Packaging?

Think of it as a pouch that's sealed on three edges, with one side open or folded. Those snack bags or instant coffee packets that you often see at the store are all conventional 3-side seal packages.

But when taking a closer look, you'll find these flat bags come in quite a few different looks. Some of them have both their top and bottom sealed, and some leave either the top or bottom open for filling.

You can find super narrow packages for things like ketchup or options with a wider opening. Plus, you can also make the packaging clear or reserve a display window on it, allowing you to see the content inside.

Additionally, many manufacturers prefer adding some features to their 3-side seal packaging: reclosable zippers, easy-open tear notches, and perfect-for-display hang holes.

3-side seal packages can be made from plastic film, kraft paper, and aluminum foil. They're sturdy enough to protect what's inside, yet light and easy to handle. Protective, convenient, and cost-effective, this flexible packaging is popular across many industries—from food to pharmaceuticals.

What is a 3-Side Seal Packaging Machine and How Does It Work?

A 3-side seal packaging machine is designed to form, fill, and seal flat pouches or bags. The finished package features a three-sided seal. So, this automated packaging device is often considered a type of FFS machine.

The operation of a 3-side seal packaging machine involves several key steps:

1. Packaging Material Feeding: A rollstock (film, paper, or foil) is loaded into the machine. It's then unwound and guided through multiple rollers and dancer arms to the next stage.

2. Pouch Forming: The packaging material passes over a forming shoulder (collar) and is folded around a forming tube, creating the shape of the pouch. The overlapped edges are then pressed vertically by heated sealing bars. One or both sides of the pouch are sealed.

3. Pouch Filling: As the sides of the pouch are formed, its bottom is sealed by horizontal sealing jaws. Products are filled into the pouch from the top. The way the product is filled varies with its type. It can be an auger feed hopper or a multi-head weigher.

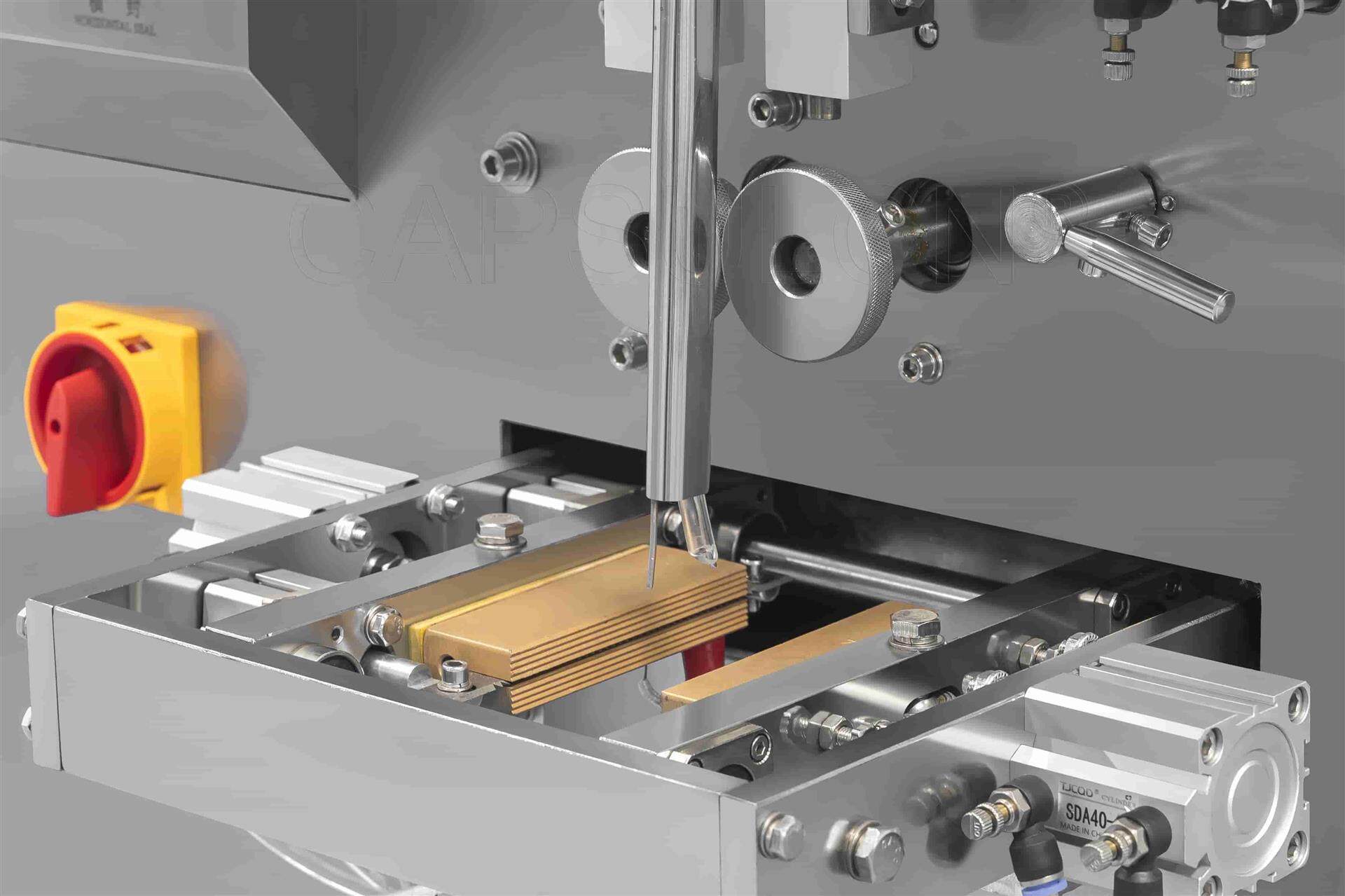

4. Final Sealing and Cutting: After filling, the opening of the pouch is sealed by the horizontal sealing jaws. By this time, the 3-side seal is complete. The filled and sealed pouch is then cut by the sealing jaws with knives.

5. Discharge: The finished pouch is finally discharged from the machine. This can involve collection in a bin or transfer to downstream equipment via a conveyor system.

For a visual demonstration of how a 3-side seal packaging machine works, you might find the following video helpful:

Why You Should Buy a 3-Side Seal Packaging Machine

Incorporating a 3-side seal packaging machine into your business is a smart move. Here are some of the compelling reasons to invest in such a packaging machine.

1. You can save money with a 3-side seal packaging machine.

The 3-side seal packaging is directly formed from a one-piece film. Plus, the forming tube of the machine is changeable based on the size of your pouch. This minimizes packaging material use. Lower costs mean more profit in your pocket—while still ensuring high-quality packaging.

2. It offers flexibility in packaging a variety of products.

3-side seal packaging machines are capable of packaging powders, liquids, or small parts. You don't have to invest in different machines for each product type. This one can handle it all, giving you less hassle.

3. It keeps your products fresh and safe.

The three airtight side seals ensure your products are protected from moisture, oxygen, and contaminants. What are you going to package? Food? Medicine? You can definitely count on this machine to maintain the high quality of your products.

4. You can enjoy endless customization options for your packaging.

Need a specific pouch size or shape? Want to add a tear notch, a zipper, or a clear window for branding? With a 3-side seal packaging machine, you have full control over how your packaging looks and feels.

5. It makes storage and shipping effortless.

The compact, flat design of the 3-side-seal pouches makes them easy to stack, store, and ship. You'll save space in your warehouse and optimize your transport. Again, it cuts down on costs and makes everything more efficient.

6. It boosts your production speed and efficiency.

Tired of slow production lines? A 3-side seal packaging machine is an automated system. Its continuous workflow speeds things up and allows you to handle higher volumes with ease. This means fewer delays and more productivity.

What to Consider When Buying a 3-Side Seal Packaging Machine

When it's time to invest in a 3-side seal packaging machine, there are several important things to keep in mind.

1. Your machine should keep up with your production demands.

Think about how much you need to package each hour or day. If your business is growing, you'll want a machine that can handle increased volumes. A faster machine can help you meet deadlines and reduce bottlenecks.

2. Different products need different packaging materials.

Check what types of packaging materials the machine can handle. Consider if the material is safe for your products. Whether you use plastic films or prefer eco-friendly options, the machine should support your specific needs.

3. Your packaging needs might change over time.

I bet you won't stick to one type of packaging or product. So, look for machines that allow you to adjust settings easily. Maybe you need to change pouch sizes or seal types? Or want additional features like zip locks or tear notches? A flexible machine can have you covered.

4. Streamlining your production process saves time and reduces errors.

Modern machines often come with smart features. Ensure the machine can integrate with your existing equipment, such as weighers, printers, and labelers, to create a seamless packaging line.

5. An easy-to-use machine saves time and reduces mistakes.

Check if the machine has an intuitive interface and user-friendly controls. Additionally, see if the supplier provides training for your staff. Proper training ensures that your team can operate the machine effectively.

6. Space on your production floor is valuable.

Check if you have enough space to place the machine. Make sure to leave enough space, not just for the machine. A well-laid-out workspace can improve efficiency and make it easier for your team to work comfortably and safely.

7. Reducing energy use helps the environment and lowers costs.

Energy efficiency and sustainability are always a hot topic in modern manufacturing. Look for machines that use less power and support recyclable or biodegradable materials. This can enhance your brand's eco-friendly image.

8. You need to balance quality with what you can afford.

Look beyond the initial purchase price. Consider the long-term costs. Sometimes, paying a little extra at the start can actually save you money in the long run.

9. Keeping your machine running smoothly is crucial.

Check what support services the vendor provides. Are spare parts readily available? Is there a team of technicians who can help you if something goes wrong? Good after-sales support means less downtime and quicker fixes.

10. A trusted brand stands for durability and performance.

Look into the vendor's reputation and check reviews from other customers. You can benefit a lot from teaming up with a reputable brand.

Noteworthy 3-Side Seal Packaging Machine Models in 2025

At CapsulCN, we pride ourselves on providing an array of 3-side seal packaging machines. Several standout models have captured the attention of the industry with their innovative features and reliable performance. Here are some top picks you might want to take a look at:

DXD-80F Automatic Powder Packaging Machine

The DXD-80F is designed for continuous automatic packaging of powders with good fluidity and loose consistency. It can package various items such as flour, coffee powder, lotus root powder, soy milk powder, milk powder, bone-strengthening powder, nutritional foods, and more.

Key Features:

² PLC control with LCD for easy operation, convenient adjustments, and high automation.

² A digital photoelectric system allows precise control of bag length and pulling speed within a specified range.

² Advanced registration mark alignment ensures accurate printing.

² Synchronized bag pulling for smooth and precise operation.

² Customizable for 3-side seals, 4-side seals, or back seals (pillow-style).

² Optional add-ons include a hot stamp coder and a tear-notch knife.

CBZ-50F Automatic Liquid Packaging Machine

The 50F is a compact vertical packaging machine developed by our company. It can handle back seals, 3-side seals, and 4-side seals. This machine can automatically complete the entire process, including pouch forming, filling, sealing, printing, tear notching, cutting, and counting. This model can handle the packaging of granules, liquids, powders, and tablets.

Key Features:

² Adjustable bag length within a set range, stable bag pulling, and adjustable speed.

² Auto stop when no film is detected, preventing operation without material.

² Self-diagnosis and fault warning system.

² High-precision PID temperature control for consistent, quality seals on various materials.

² Simple structure for easy operation and maintenance.

² Versatile design with interchangeable filling heads for different applications.

² Automatic batch number printing and optional tear notches.

² Durable, low-noise components with a long service life and low failure rate.

BVL-520 VFFS Machine

The BVL-520 is a top-notch, high-performance VFFS machine designed for large-scale production. Developed by our team using cutting-edge technology from abroad, this model works seamlessly with other packaging equipment, fully automating the entire packaging process. It's the top choice for those in the food and pharmaceutical packaging markets.

Key Features:

² Reliable electrical and pneumatic components from top brands for stable operation.

² PLC control with a bilingual (Chinese/English) touchscreen for easy use and clear status updates.

² High-precision servo film feeding and photoelectric positioning ensure smooth, accurate operation.

² Intelligent digital temperature control and a toothed sealing mechanism provide reliable sealing.

² Automatic fault alerts for issues like missing film or low temperature, with options for automatic stops or alarms.

Wrap-Up

A 3-side seal packaging machine is a solid investment if you want to speed up your packaging and make it more efficient and flexible. Whether you're packaging snacks, supplements, or other products, these machines offer awesome customization options, save you money, and keep your products fresh and secure. We hope this guide helps you pick the perfect machine for your needs!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche