Delve into the Advantages of Tablet Counting Machines

Are you looking to streamline your tablet counting process? If so, you're in the right place! When it comes to counting tablets and capsules efficiently, tablet counting machines are your trusty allies. No matter what type you're interested in, these machines will make your production easier.

Whether you're in the pharmaceutical, nutraceutical, food, or other manufacturing industries, tablet counting machines can revolutionize your production line with a host of benefits. This article will delve into the world of tablet counting machines. After the reading, you will know why these machines are indispensable tools for your business.

What is a Tablet Counting Machine?

First, let's take a brief look at what a tablet counting machine is. Tablet counting machines are designed to accurately count tablets, capsules, or pills. They are effective tools for precise packaging in pharmaceutical, nutraceutical, and other industries. Tablet counting machines are mainly available in three types on the market:

- Manual

- Semi-automatic

- Fully automatic

8 Advantages of Employing a Manual Tablet Counter

In modern tablet manufacturing, automation often takes center stage. However, the benefits of manual tablet counting should not be overlooked.

1. Budget-Friendly: Manual tablet counters won't break the bank. They're way more affordable than those fancy automated machines. This makes them a smart choice, especially when you're running a smaller business or just starting up with limited funds.

2. User-Friendly: Manual tablet counters are pretty easy to use. Operators can get the hang of them without needing a lot of training. This saves you time and money on training programs.

3. Precise and Accurate: Even though these tablet counters are hand-operated, they are pretty darn accurate. They're great for counting small to medium-sized batches. Operators can eyeball those tablets and double-check each count during the process. This helps to keep product quality in check.

4. Perfect for Experimenting: If you intend to develop new products or tweak formulations, manual tablet counters are ideal for small-scale testing and research. You can make quick adjustments without dealing with big, expensive equipment.

5. Easy to Move Around: Manual tablet counters are usually not heavyweights. They are small and lightweight, so you can easily move them around your manufacturing facility. These devices come in handy when you need to count tablets at different manufacturing stages.

6. Low-Maintenance: Unlike those automated machines with a plurality of moving parts, manual tablet counters have way fewer components. Maintenance and cleaning are a breeze thanks to their easy assembly and disassembly.

7. Trusty Backup: Manual tablet counters play the role of your trusty sidekicks when your automated machines act up or the power goes out. These counters keep your production process going smoothly without interruption.

8. Eco-Friendly: Here's a bonus – manual tablet counters don't guzzle electricity. They're eco-friendly, helping you save on energy costs and do your part for the environment.

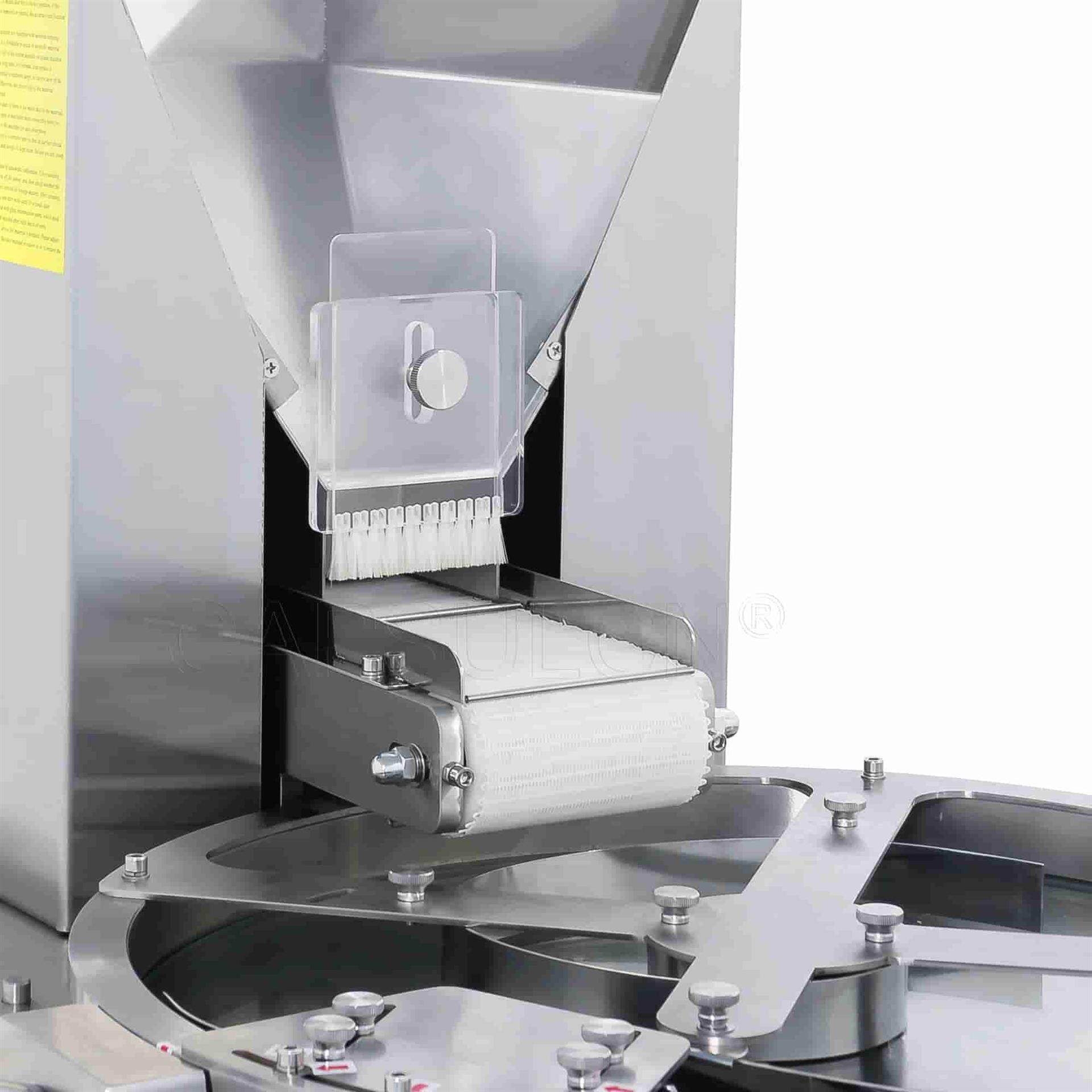

The Go-to Manual Pill Counter Worth Buying: CN-50MC

Thanks to durable construction and precise counting ability, the CN-50MC is one of the best-selling tablet counting machines offered by iPharMachine. This dependable manual pill counter has many features that make it stand out.

|

|

|

FEATURES:

- Crafted from American standard 304 stainless steel

- Incorporates cutting-edge capsule filling technology

- Capable of accommodating different capsule sizes

- Allows for easy adjustment of the number of capsules to be counted

- Facilitates fast and efficient bottling of counted capsules

- Utilizes a buffer-intact design to prevent capsule damage during counting

- Speeds up the counting process, achieving up to 80% faster results

- Designed to cater to both occasional and regular counting for small-scale batches

8 Perks of Semi-Automatic Tablet Counting Machines

Semi-automatic tablet counting machines are a hybrid of manual and fully automated options. Let's take a look at the advantages of incorporating a semi-automatic tablet counting machine into your production process.

1. Cost-Effective Automation: Ever considered the idea of cutting costs while still enjoying automation? That's where semi-automatic machines step in. They handle the counting process with way less manual input. You can get all the benefits of automation without high initial costs.

2. More Productive: Semi-automatic machines count tablets than manual devices. You can get more tablets counted and filled in a shorter time. These machines are great for boosting your productivity.

3. Higher Accuracy: These machines are proven to increase tablet counting accuracy and consistency significantly. With them, you can trust that each bottle is filled with just the right number of tablets, no more, no less.

4. Versatile: Semi-automatic counters are capable of handling tablets of all shapes, sizes, and materials. So, whether you're dealing with various products or tweaking your formulations, they're up for the task.

5. User-Friendly Interface: Many semi-automatic counters boast an intuitive interface. Operators can easily set and adjust counting parameters, and the best part? No need for extensive training.

6. Reliable: These machines are like your dependable old car. They're built for reliability with minimal downtime. And when it comes to maintenance, it's as easy as changing the oil in your car.

7. Scalable: Depending on the models and brands, some semi-automatic machines can work with other automated equipment like a bottle conveyor. Some can easily be incorporated into existing production lines to ensure a seamless manufacturing process.

8. Less Labor Intensive: Semi-automatic machines significantly reduce the labor intensity for counting compared to manual counters. This can save time and minimize human error.

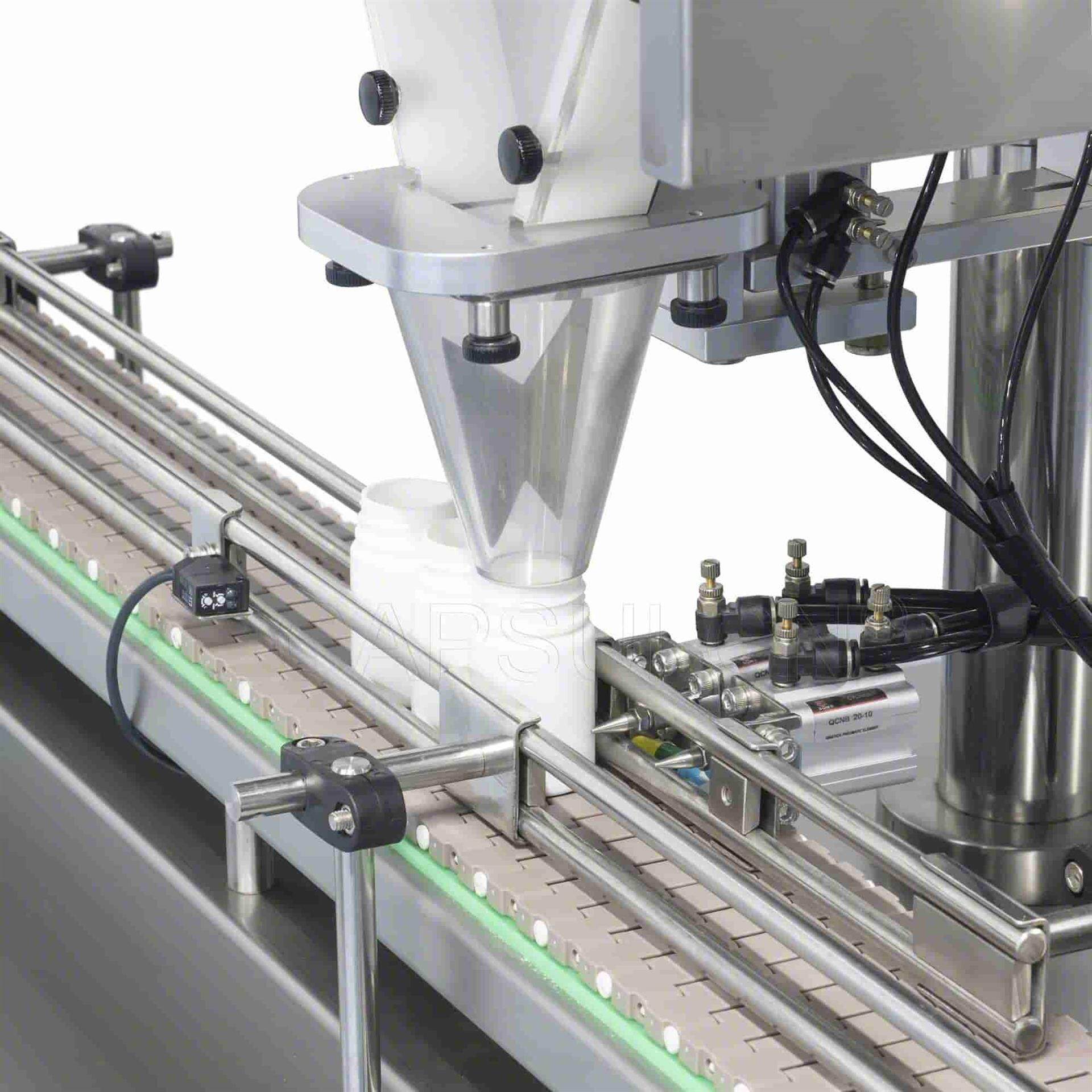

The Best Semi-Automatic Tablet Counting Machine You Can't Miss: CDR-3A

The CDR-3A is an iconic product from the iPharMachine tablet counting machine lineup. It's designed to handle tablets, capsules, pills, and softgels. The machine is capable of counting and filling 1000-2000 pieces per minute.

|

|

|

FEATURES:

- All contact parts are constructed from SUS316

- Easily exchangeable components for facilitating maintenance and repairs

- Designed to accurately count and fill a wide range of products

- Flexible counting with an adjustable range from 1 to 9999 pieces per bottle

- Utilizes a rotary system with a computerized counter for high counting accuracy

- Incorporates an infrared recognition system

- Effectively prevents dust build-up

- Equipped with a feed conveyor to accommodate different production needs

10 Benefits of Using Automatic Tablet Counting Machines

Fully automatic tablet counting machines represent the pinnacle of tablet counting technology. Compared to manual and semi-automatic machines, they offer many more benefits to optimize your production process. Let's check them out!

1. High Throughput: Need to handle a colossal load of tablets? Automatic counters have your back. They thrive on high production volumes, making them perfect for large-scale batches.

2. Exceptional Speed: Imagine tablets filling bottles at a pace that would make a hummingbird's wings look sluggish. That's what these automatic counting machines bring to the table. They significantly outpace manual or semi-automatic methods. Result? You're cranking out more products in less time.

3. Unparalleled Accuracy: If semi-automatic counters greatly improve tablet counting precision, automated machines can take your production to the next level. With advanced counting technology, these machines ensure each bottle gets precisely the right number of tablets. That's error-proof production right there.

4. Consistency: Consistency is the secret sauce in manufacturing. Automatic counters serve up a generous helping of it. Regardless of the product, you get uniform tablet counts every single time. No more worries about quality or meeting regulatory standards.

5. Hands-Free Operation: Once set up, these machines are practically autonomous. Your skilled workforce can step away from the counting conveyor belt and focus on more critical tasks. Fewer hands-on-deck means reduced labor costs.

6. Tailored to You: These machines aren't one-size-fits-all. They often come with user-friendly interfaces that let you customize counting parameters, batch sizes, and filling options. Your production, your rules.

7. Quality Control: These automatic tablet counting machines feature reject systems that weed out bottles with incorrect counts or defects. They only bring the highest-quality products to market.

8. Minimizing Waste: Backed by precise counting and filling, these automated machines can minimize waste during production. Using these machines will save costs and lower your carbon footprint in the long run.

9. On-demand Scalability: These machines can grow with you if you intend to expand your business. They're designed to seamlessly integrate into production lines or team up with other automated equipment, creating an efficient workflow.

10. Long-Term Payback: While the initial investment is higher than manual or semi-automatic options, these machines can bring you long-term cost savings, increased production capacity, and reduced labor costs. So, it's a smart financial move to invest in an automatic tablet counting machine.

The Must-Have Automatic Tablet Counting Machine: PBDS-8

The PBDS-8 is a fully automatic counting and filling machine for tablets, capsules, pills, and other solid dosage forms. Powered by cutting-edge technology, this machine is capable of filling up to 50 bottles per minute.

|

|

|

FEATURES:

- Designed for precise counting and filling in large-scale production environments

- Employs a high-speed PLC system that manages the entire process

- Operates smoothly with minimal noise, ensuring stable performance

- Incorporates unique anti-dust photoelectric sensors to maintain accuracy

- Tool-less design for hassle-free cleaning and maintenance

- Dust extraction system for keeping the workplace clean and safe

- Allows for height adjustment according to the bottle's size

- Equipped with a voltage stabilizer to ensure stable power supply

- Allows for the storage of up to 15 groups of setting parameters in memory

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche