Aluminum Tube Packaging: A Comprehensive Guide

Aluminum tubes are a tried-and-true packaging solution from way back. While plastics were all the rage for a while, growing environmental awareness has brought aluminum tubes back into the spotlight. They're durable, recyclable, and look great. You can use them for everything from cosmetics to pharmaceuticals. Their smooth metallic surface makes the product look and feel premium, which is great for a lot of different industries.

What Is Aluminum Tube Packaging?

Aluminum tubes are a cost-effective, eco-friendly way to package a wide range of products, from pharmaceuticals and food to industrial chemicals. Aluminum tubes protect and preserve substances like ointments, medications, and condiments.

There's a wide range of tubes to choose from, in different shapes and sizes, from sleek cylinders to oval collapsible containers. Whatever product you need, you'll find the right tube to fit. The metallic finishes look great, and the material also blocks light, oxygen, and moisture, keeping your product fresh and intact.

Aluminum tubes have been around since the 19th century. While they were first made as paint canisters, they quickly became the go-to packaging choice for businesses and consumers alike because they're so versatile. You can use them for toothpaste, other products, and even recycling programs.

What Are the Benefits of Aluminum Tube Packaging?

There are so many benefits to aluminum tube packaging for different industries. It's great for cosmetics, pharmaceuticals, and food products. Here are some of the main reasons why:

- Lightweight and Tough

Aluminum tubes are lightweight, which makes them cost-effective to ship and store. Even though they're lightweight, they're super durable and resistant to breakage. Thus, your products will be safe during transportation and handling.

- Airtight and Moisture-Resistant

Aluminum tubes do a great job of keeping out air and moisture, which helps to keep product contents safe from oxidation and degradation. This is especially important for cosmetics and pharmaceuticals.

- Recyclable and Sustainable

Aluminum is one of the most recycled materials, so it's a great eco-friendly packaging choice. Recycling uses way less energy than making new aluminum. And, it has a smaller carbon footprint.

- No Preservatives Required

Aluminum tubes keep out air and bacteria, so you don't have to add as many preservatives to your products. This is great for consumers looking for natural and organic products.

- Customizable and Modern

You can customise your aluminum tubes however you like. They come in various sizes and shapes. Also, they have a range of finishes to match your brand and product. Aluminum tubes look modern, which makes the product more appealing and gives the consumer a better experience.

What Are the Different Applications of Aluminum Tubes Packaging?

Aluminium tubes are used all over the place in lots of different industries. They're great because they're durable, eco-friendly, and they look good.

Cosmetics Industry

You'll find aluminium tubes everywhere in the cosmetic industry. People use them to package products like lipsticks, mascaras, foundations and creams. They're a popular choice because of their sleek design and ability to protect delicate formulations.

Personal Care Industry

Aluminium tube packaging is also ideal for the personal care industry, especially for products like toothpaste, shampoo, soaps, hand sanitizers, body wash, and hair gels. These tubes are simple to use, hygienic, and convenient to dispense products.

Pharmaceutical Industry

Aluminium tubes are a popular choice in the pharmaceutical industry for packing ointments, creams and gels. Their airtight and moisture-resistant properties help keep products safe and fresh for longer.

Food Industry

We're seeing more and more food businesses using aluminium tubes, especially for packaging condiments, sauces and other food products. They're a great, hygienic solution for when you're on the go.

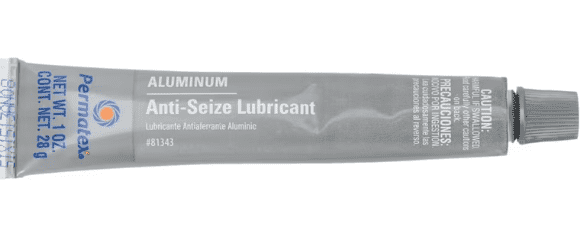

Industrial and Automotive Industry

Aluminium tubes are also used in industry and cars for packaging products like lubricants, adhesives, sealants, paints and coatings. These tubes are perfect for protecting and keeping things durable, which is exactly what you need them to do in these challenging applications.

Are Aluminum Packaging Tubes Recyclable?

Aluminium is very recyclable. You can recycle aluminium tubes as many times as you like without any loss in quality. This makes them a valuable resource for a circular economy. Plus, it takes less energy to recycle aluminium than to make it. This helps reduce greenhouse gases and conserve resources.

If businesses choose aluminium tube packaging, they can help to reduce their carbon footprint and contribute to a more sustainable future. This move away from single-use plastics fits in with global plans to cut down on waste and look after the environment.

Is Aluminium Safe for Pharmaceutical Packaging Tubes?

Aluminium is used a lot in pharmaceutical packaging, including tubes. Some people are worried about aluminium leaching into products, but scientific studies have shown that it is safe for pharmaceutical use when used correctly.

Even better, many manufacturers use a thin, inert coating on the inner surface of aluminium tubes. This coating stops the product touching the aluminium, and it makes sure the product stays pure and free from contaminants.

Aluminum vs. Plastic Tubes: What Are their Differences for Pharmaceutical Packaging?

Aluminium and plastic tubes are two of the most common types of packaging for pharmaceutical products. Both work well, but they have very different effects on the environment, the materials they are made from, and how well they suit different types of drugs. Here's a quick overview of the main differences between the two.

|

Feature |

Aluminum Tube |

Plastic Tube |

|

Material |

Pure aluminum (bauxite ore) |

Polyethylene (HDPE or LDPE) |

|

Manufacturing Source |

Naturally occurring metal |

Fossil fuels (natural gas, oil) |

|

Barrier Properties |

Excellent barrier against air, moisture, and light |

Moderate barrier properties |

|

Sterilization |

Easily sterilized |

More difficult to sterilize |

|

Durability |

Durable and resistant to breakage |

Susceptible to damage and deformation |

|

Recyclability |

Infinitely recyclable |

Limited recyclability |

|

Environmental Impact |

Lower environmental impact due to recyclability and energy-efficient production |

Higher environmental impact due to reliance on fossil fuels and limited recyclability |

|

Cost |

Generally higher cost |

Lower cost |

So how do you pick the right material to package your product?

There are lots of things to think about when you're choosing the best packaging material. Some of the main factors are:

- Product sensitivity - If you've got a sensitive formulation that needs to be kept as safe from light, air, and moisture as possible, then aluminium tubes are your best bet.

- Product viscosity - Aluminium tubes are great for viscous products like ointments and creams, while plastic tubes are better for thinner liquids.

- Shelf life - Aluminium's great at keeping products fresh for longer, especially when they're sensitive.

- Regulatory compliance - Both aluminium and plastic tubes have to meet specific regulatory standards for pharmaceutical packaging. This includes things like material compatibility, sterilisation processes and labelling requirements.

By thinking carefully about these things, pharmaceutical companies can choose the best packaging material for their products and what customers expect.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche