An Informative Guide to the Hardness of Tablet

One of the most popular solid dosage forms, tablets offer a simple and precise way to take medication or supplements. No matter they are everyday aspirin or vitamins, these small pills are carefully created to deliver the right dose. If you're making tablets, there is a crucial factor that you should never overlook: the hardness. Looking to produce high-quality tablets? Keep reading. We'll shed light on everything you need to know about the tablet's hardness.

What is the Hardness of Tablet?

Tablet hardness is essentially how much pressure a tablet can handle before it breaks. In other words, it's an indicator of measuring the force required to crush or break a tablet. The hardness matters as it ensures that tablets can remain intact and survive packaging, shipping, and handling.

Quality tablets should neither be too hard nor too soft. If not, these tablets may become hard to dissolve in the body or fail to bind ingredients well together. So, getting the right hardness ensures that the tablet works effectively.

Why is the Hardness of Tablet So Important?

When making tablets, please pay attention to their hardness. Why? Here are several reasons:

1. The hardness keeps the tablet intact. Any products should reach users in good condition, not to mention the medication. Proper hardness prevents the tablet from breaking apart, whether it's being made, packaged, or shipped.

2. The hardness ensures each tablet has the right dose. A tablet is a combination of various active ingredients. A broken tablet can become less potent. The right hardness helps make sure every tablet releases the same and the correct dose every time patients take one.

3. The hardness affects how the tablet works in the body. If a tablet is too hard, it might not dissolve in the right place at the right time. This can delay the medicine from working. If it's too soft, it could crumble before you even take it.

Factors Influencing the Hardness of Tablet

Then, how do you get the proper tablet hardness? Several factors need to be controlled.

- Composition of the Tablet

Tablets are typically formulated with active ingredients and excipients. The balance (type and amount) between these components is essential to the hardness of tablets. Some APIs may affect tablet compression, thereby causing unstable hardness. Excipients like binders are important to the hardness as well. They bind ingredients together to achieve the desired crushing strength of the tablet.

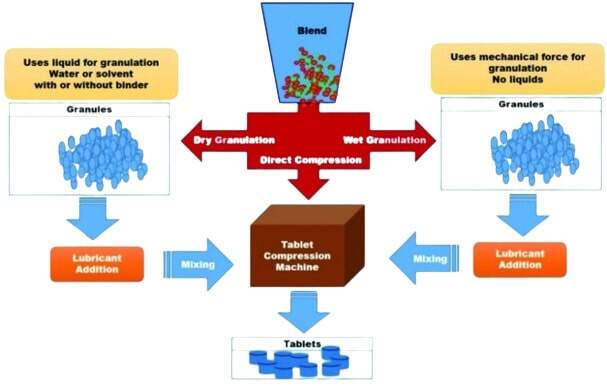

- Granulation

Granulation is a process that allows for easy compression of tablets. Well-processed granules compress uniformly. This helps achieve optimal hardness. By the way, dry granulation may result in softer tablets, and wet granulation usually brings harder tablets.

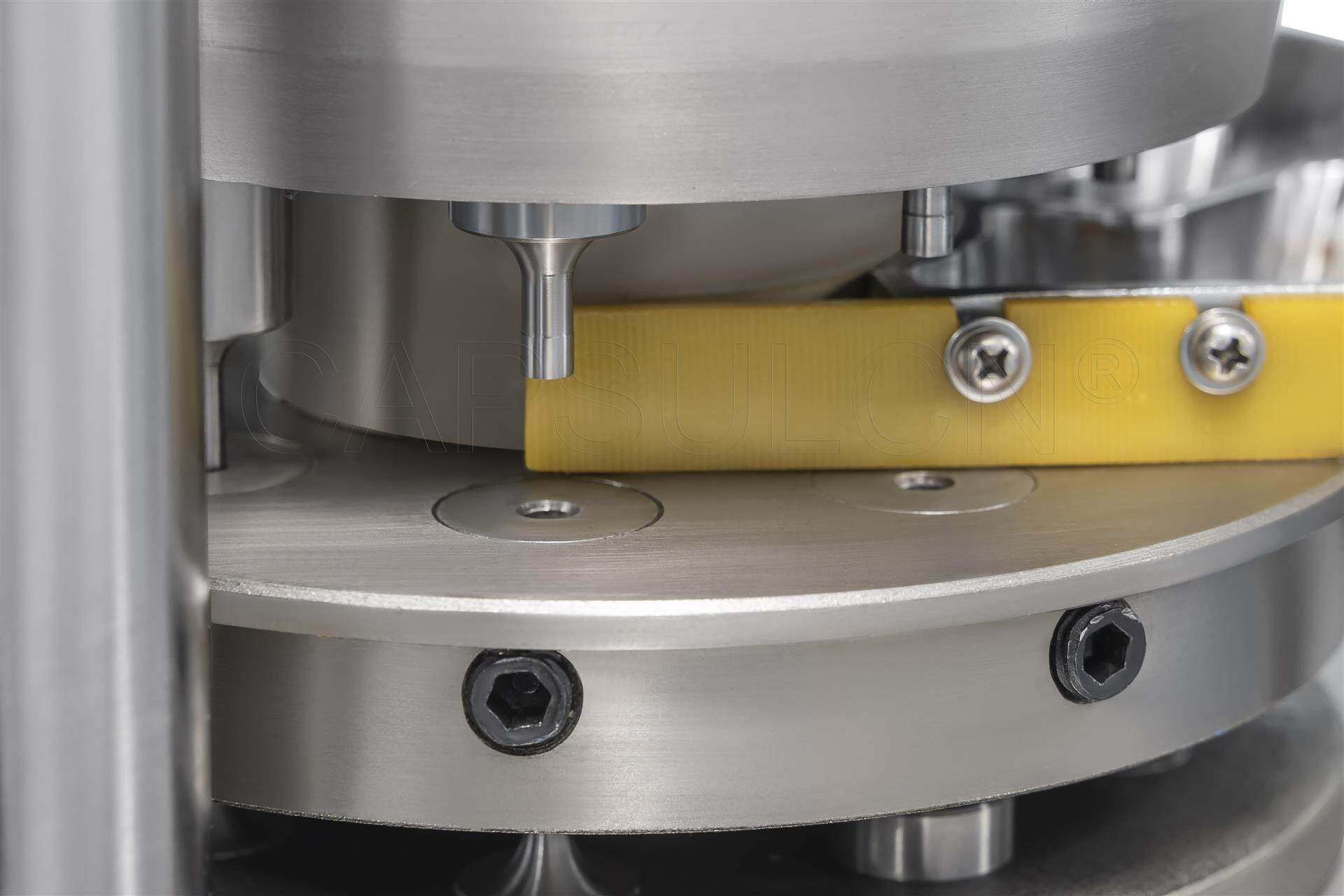

- Compression Force

This factor directly affects the hardness of tablets. Tablet manufacturing requires pressure to compress all ingredients into a solid pill. Higher compression forces usually result in harder tablets. However, note that too much force can cause capping and sticking.

- Type of Equipment Used

The tablet press you're using can also influence the tablet's hardness. Different machines may have different speed and pressure settings.

- Size and Shape of the Tablet

Typically, when making larger tablets, more compression force is required to achieve the same hardness as smaller ones. So, the hardness of a tablet can vary based on physical dimensions and shape.

Measuring the Hardness of Tablet

Now that hardness is such an important factor in tablet quality, how can we get the right hardness? Measuring is a critical step. Here's how this is typically done:

Common Units of Measurement

- Kiloponds (kp): Traditionally used in some regions.

- Newtons (N): A universal unit reflecting the international system of units.

- Pounds (lb): Sometimes used for testing in the United States.

- Strong Cobb Units (SCU): An old-fashioned unit of force.

- Kilogram-force (kgf): A unit of force equivalent to the gravitational force exerted by one kilogram.

▲1 kp = 9.8 N = 2.2 lb = 1.4 SCU = 1 kgf

Types of Hardness Tests

1. Crush Test: This test measures the force required to crush a tablet by applying a direct compression force.

Steps:

‐ Place the tablet sideways on a stable surface.

‐ Lower a cylindrical probe directly onto the tablet and press it.

‐ Continuously measure the force applied until the tablet breaks.

‐ Record the peak force required for the tablet to fracture.

2. Fracture Test: This test evaluates the point at which a tablet breaks under a concentrated load.

Steps:

‐ Set the tablet under a hemispherical probe.

‐ Press the probe into the tablet at a controlled speed.

‐ Monitor the force exerted as the tablet fractures.

‐ Capture the maximum force at fracture.

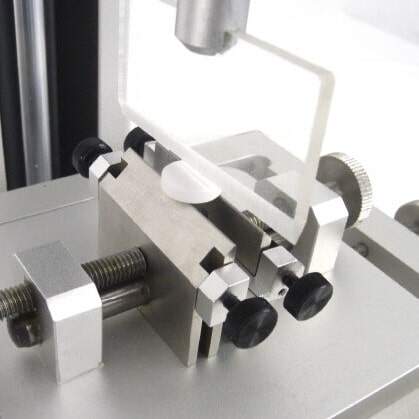

3. Bending Test: It's also called the 3-point bend test. It's used to assess the tablet's flexibility and point of failure when bent. This testing is ideal for caplets or large tablets.

Steps:

‐ Position the tablet on two supports spaced appropriately apart.

‐ Apply a force at the center of the tablet using a knife-edge probe.

‐ Increase the force gradually until the tablet snaps.

‐ Document the force at which the break occurs.

4. Compression Testing: This testing method helps determine the mechanical integrity of the tablet, ensuring it can withstand handling and packaging without breaking prematurely.

Steps:

‐ Place a tablet between two platens or jaws of the tester.

‐ One platen moves to apply a controlled force to the tablet until it fractures.

‐ The tester uses a calibrated load cell to measure the force applied.

‐ The peak force is recorded as the tablet breaks, typically in Newtons or Kiloponds.

Tools Used for Measuring Hardness

Hardness testers are specifically designed to assess the mechanical strength of a tablet.

- Manual Hardness Testers: Require human operation to apply force and measure the breaking point.

- Automatic Hardness Testers: These are more advanced and use automated systems to apply a consistent force, providing more precise and reproducible results. They often include digital displays for easy reading of the hardness value.

Frequently Asked Questions on the Hardness of Tablet

Q: What are the industry standards for tablet hardness?

Tablet hardness typically ranges from 4 to 10 kp, though softer tablets like chewables may be around 3 kp. Regulatory bodies like the FDA and EMA don't set specific hardness values but require manufacturers to set and validate their own hardness standards to ensure tablets are durable yet dissolve effectively.

Q: How does tablet hardness relate to other quality parameters like weight and thickness?

Uniform weight helps ensure consistent hardness across tablets, as variations can affect the required compression. Thicker tablets may need more compression to achieve the same hardness as thinner ones, impacting how they dissolve and disintegrate.

Q: What are common challenges in controlling tablet hardness, and how can they be overcome?

- Start by thoroughly checking the properties of your raw materials. Using pre-processing steps like milling can really help to make these materials more uniform.

- It's crucial to keep your tablet press in top shape. Regular maintenance and calibration, along with real-time monitoring, ensure it creates tablets with optimal hardness.

- Managing the temperature and humidity in your manufacturing space is another important step. Keeping these environmental factors stable supports uniform tablet hardness throughout your production process.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche