Getting to Know the Auger Filling Machine Design

When it comes to powder packaging, auger filling machines are one of the most common packaging systems used across the process industries.

What are auger filling machines and how do auger filling machines work? An auger filler is a packaging machine that uses an auger, or a screw-like device, to dispense an accurate dose of product into containers. They are typically used to fill products such as powders, granules, pastes, gels, and other similar products by many food and beverage, pharmaceutical, chemical, and cosmetic companies.

If it's your first time buying an auger type powder filling machine or you're just interested in this equipment, it will be better to get to know the auger filling machine design before making the investment.

This post will walk you through everything you need about the diagram, design, and major parts of the auger filling machine. Let's get started!

Auger Filling Machine Design

Auger filling machines can be divided into semi-automatic and fully-automatic systems. Though there is a difference in the level of automation, these machines are composed of similar major parts and components.

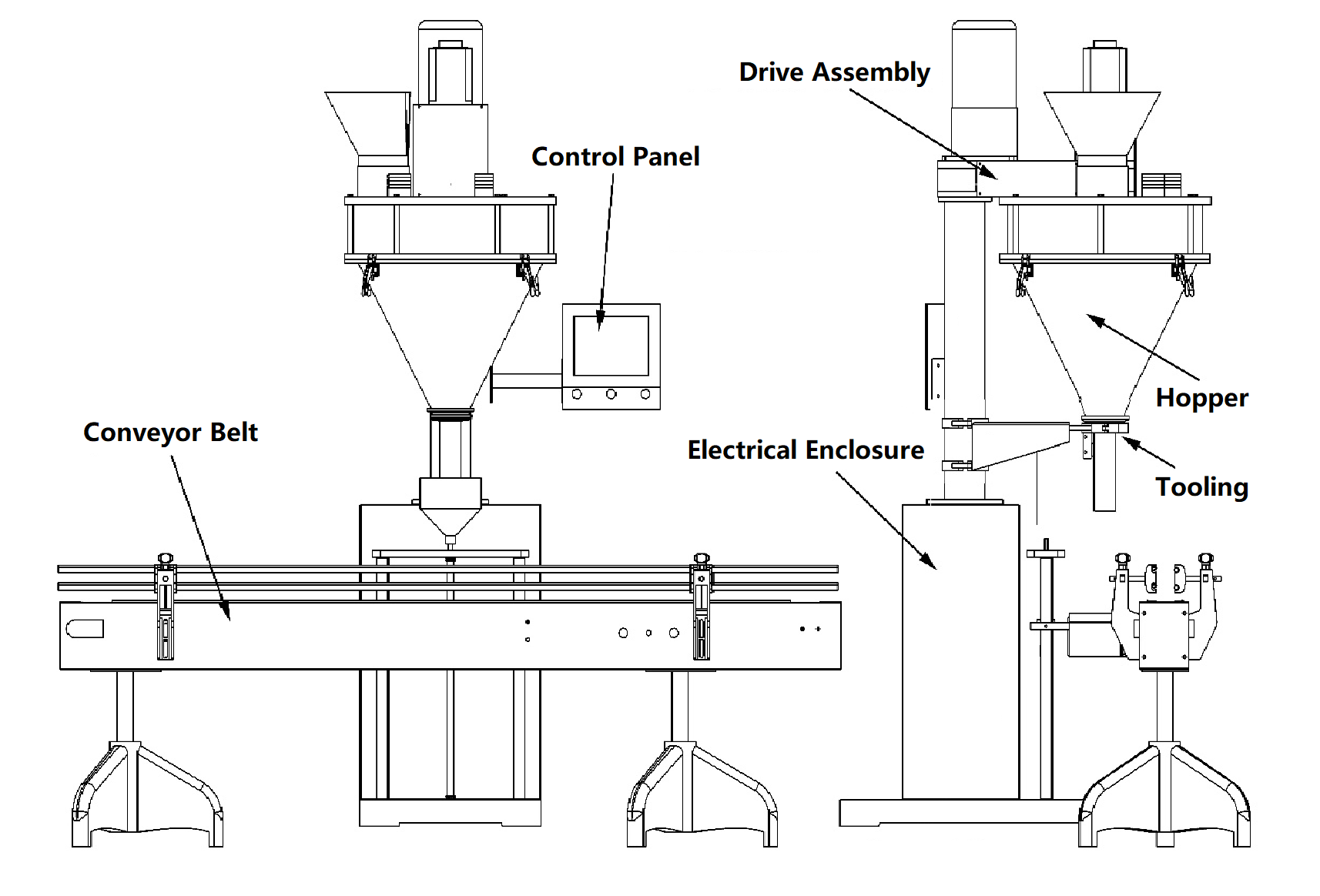

We can start with its structure when talking about the auger filling machine design. An auger filling machine typically comes in a rugged stainless steel construction. It's made up of a drive assembly, hopper, tooling, control panel, and electrical enclosure.

The semi-automatic type usually comes with a foot switch to control each fill cycle. Some semi-automatic auger fillers are upgradeable. They can be turned into fully-automatic ones by integrating with a conveyor and other support equipment.

Auger Filling Machine Diagram

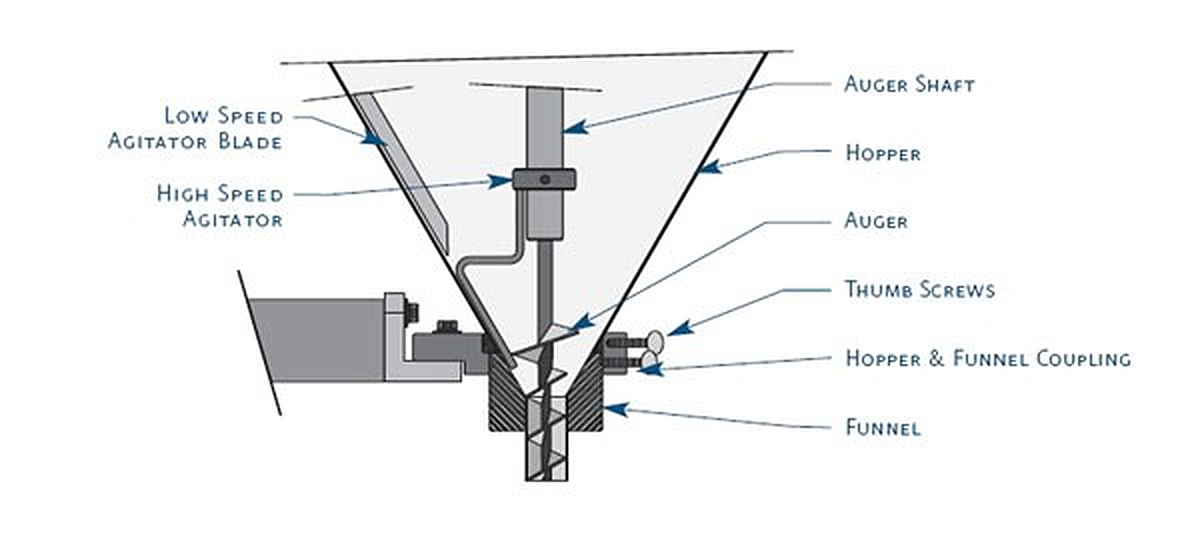

Let's now picture how these parts enable the auger filling machine to work. Below are an automatic auger filling machine diagram and a closeup diagram of the filling part. These drawings will help you get to know the auger filling machine design in a more intuitive fashion.

Powder stored in the hopper is fed into the auger tooling. The tooling consists of an auger, an agitator blade, and a funnel. Two motors mounted atop the filler offer separate precise control over the rotation of the auger and the agitator blade. The auger rotates to move the product down to the funnel, while the agitator blade works to prevent any product buildups or leftovers in the hopper.

The auger directs the product to the funnel, where it is dispensed into the container. The fill volume is controlled by adjusting the auger speed and the fill cycle. And then, the conveyor transports the filled container to the next station of the packaging line.

7 Critical Auger Filling Machine Parts

As you can see in the above auger filling machine diagram, this piece of equipment typically consists of the following parts:

1. Drive Assembly

The drive assembly of auger filling machines features two independent motors. These motors are responsible for rotating the auger and agitator blade while controlling their speed.

This assembly can be electric, pneumatic, or hydraulic, depending on the configuration of the machine. The drive assembly with precise control is helpful for reliable and efficient filling operations.

2. Hopper

The hopper is the storage area for the product that needs to be filled. This component is usually crafted from sanitary stainless steel because of its superior corrosion resistance and ease of maintenance.

The hopper comes in a split construction with quick-release clamps. This offers easy access to cleaning and maintenance. Some hoppers feature transparent viewing glass, allowing you to check the condition inside the hopper.

3. Auger + Agitator Blade + Funnel

The tooling part lies at the center of the performance of an auger filling machine. This assembly consists of an auger, agitator blade, and funnel.

- Auger

The auger is a screw-like component that moves the product from the hopper down to the container. The auger speed is adjustable to control the flow rate of the product.

Depending on your filling needs, this component can be fabricated from plastic or stainless steel. The auger must be made to handle the product's weight and roughness. Also, it should be easy to disassemble for cleaning and maintenance.

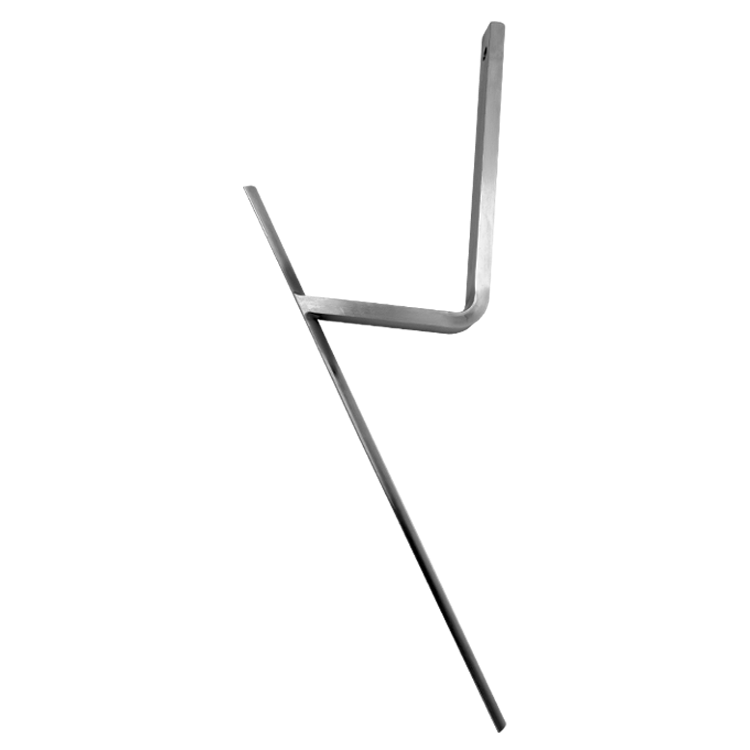

- Agitator blade

An agitator blade in an auger filling machine is a rotating component used to stir and mix the product to be filled. Using the agitator blade ensures a homogeneous blend. This helps dispense the product evenly into the auger flights, reducing the risk of waste or overfilling.

The agitator blade is typically driven by a motor. The speed and direction of rotation of the agitator blade can be adjusted to accommodate different formulations.

- Funnel

The funnel is one of the most important auger filling machine parts. It works to guide the product into containers. Depending on the product, the desired fill accuracy, and speed, this component can be customized.

Some funnels may also be equipped with adjustable gates or other flow-control devices to regulate the flow of product into the container.

4. Control Panel

The control panel allows operators to easily adjust and control various parameters of the machine, such as the auger speed, fill volume, and filling speed.

The control panel should be user-friendly and have clear displays and buttons for easy operation. Some machines are built with a PLC-based touchscreen, allowing operators to perform tasks faster and with fewer steps.

5. Conveyor

In order to facilitate the process of automated powder filling, the conveyor is used to carry containers such as bottles, jars, and pouches from the previous to the next station.

The conveyor is typically constructed with container holds, variable speed controls, adjustable guide rails, and photoelectric sensors.

As one of the major auger filling machine parts, the conveying system efficiently increases the machine's automation level. In the meantime, it enables the auger filler to be compatible with either a new or an existing manufacturing line.

6. Sensors

Most auger filler machines are equipped with sensors to monitor product level, container presence, and fill volume. These sensors can alert the operator by sending an audible or visual signal if detecting errors.

Also, the sensors are packed with various technologies to help enhance accuracy and productivity.

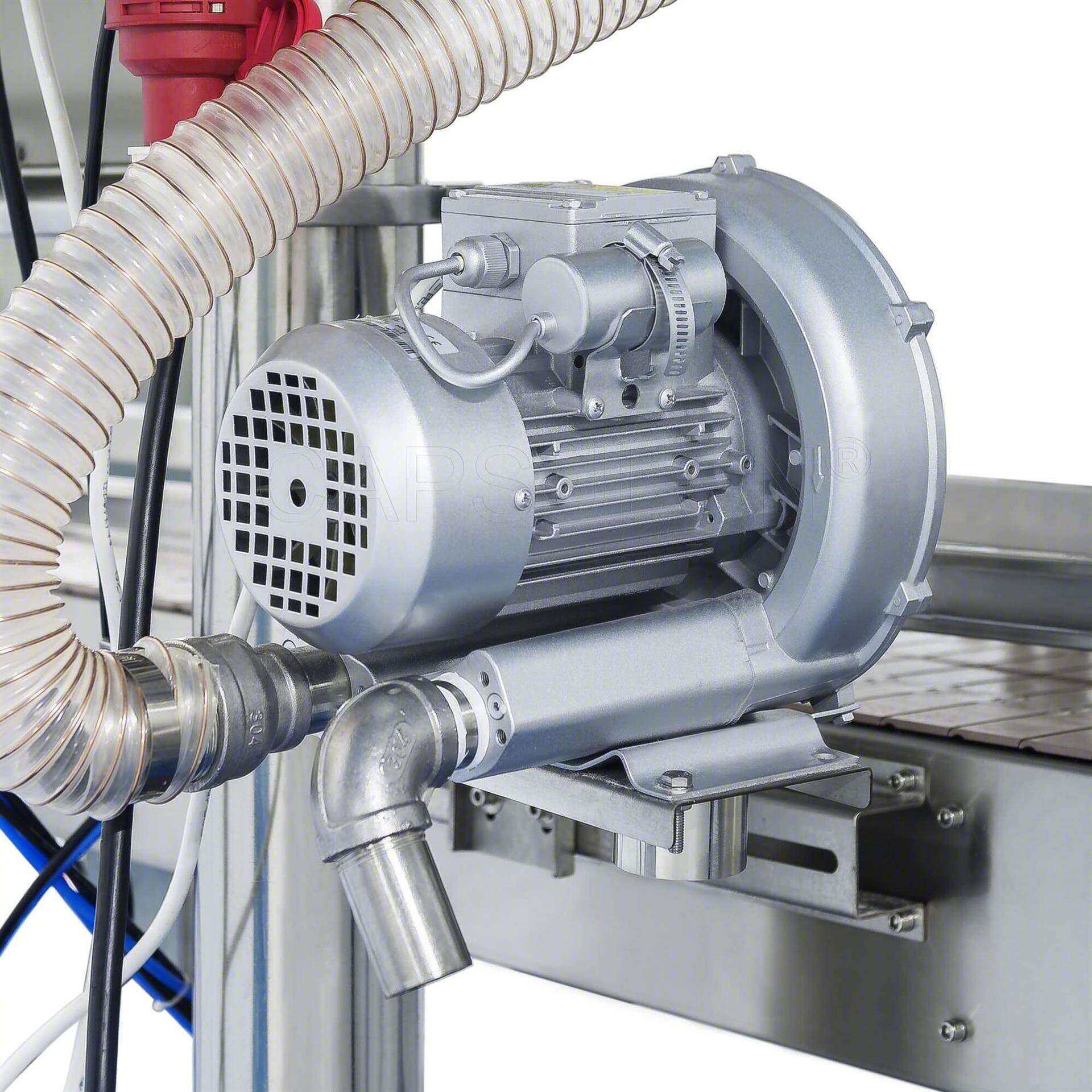

7. Compressed Air System

A compressed air system is also one of the critical auger filling machine parts. It's used to operate the pneumatic components of the machine, such as the drive system.

Further, this system is designed to control the flow rate of the product, allowing the operator to make fine adjustments to the fill volume.

The compressed air system must be carefully designed and maintained. This ensures reliable, accurate, consistent, and efficient filling applications.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche