Automatic Capsule Filling Machine NJP Series Operation Guide of the Touch Screen

Thanks for purchasing the full automatic capsule filling machine produced by our company.

This operation manual clearly introduced the working process, method and related cautions for the whole universal type automatic control system. Before you use this control system, please read this operation manual carefully to make sure you use it correctly.

Safety caution

Before installation, running, maintenance, inspection, please read this operation manual and its attached files in order to use it correctly. Also please use it after you have a good knowledge of the equipment details, safety information and cautions.

Attention:

- please install it on incombustible things like metal to avoid fire

- Please don’t get close to combustible things, and please put down gently when carry them.

- Connect the wire only when you make sure the power is off, and also please make sure the earth wire is connected. Please entrust the professional electrician to connect the wire and after that please also inspect ifthere is any error in order to avoid any electric shock or fire disaster.

- Please don’t operate the interface or button with wet hand, people who are not appointed are not allowed to do the maintenance, inspection or changing the parts. ( Before doing this, please take off the metal things like watch) Please use the insulated protective tools to avoid electric shock or any hurt.

- Please don’t change the electric control system at will, in case the machine can’t run normally. The machine can’t be operated in the open air .Also please pay attention to the water proof and dust proof.

- The machine should be operated and maintenance by the professional person, please don’t change the circuit at will.

- Before start the machine, please check the power supply circuit and if there is anything inside the machine.

- Machine should be earthed.

- The machine operator should be trained before operate the machine.

1. Turn on the power switch, enter the home screen as shown in Fig to choose the language

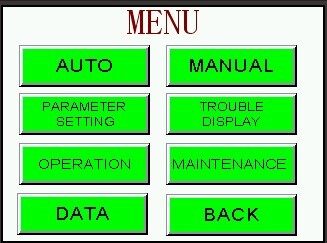

2. Press ENGLISH to enter operation menu as shown in Fig.

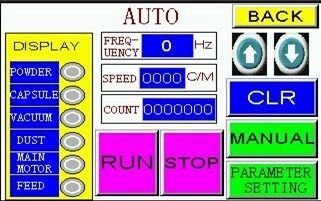

3.Press AUTO to enter Fig.

The operation steps are as following;

A-Press RUN/STOP button in Gig to realize the whole machine operation.

B-The UP/DOWN is to adjust FREQUENCY/SPEED to control the machine speed.

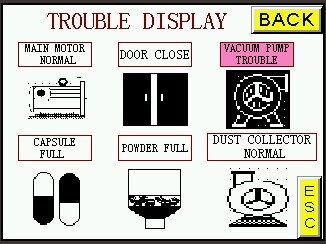

C-In Fig, when there is any failure, or the door is not well closed, it will jump to the display as following:

Check the failure and solve it, press ESC , then press BACK to come back to Fig to start new operation.

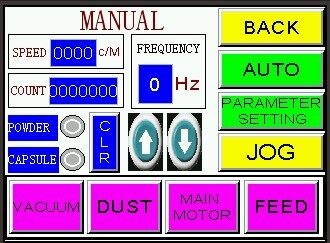

4. Press MANUAL in Fig to jump to this following display.

A- UP/DOWN in Fig is to adjust the main motor speed.

B-Keep pressing on JOG, the main motor start to rotate, loose it the main motor stop rotating.

C-Press VACUUM for once, the vacuum pump is turned on, press it again, vacuum pump is turned off.

D-Press DUST for once, the dust collector is turned on, press it again, the dust collector is turned off.

E-Press MAIN MOTOR for once, the main motor will start, press it again, the main motor is turned off.

F-Keep pressing on FEED, the feeding motor start to rotate, loose it the feeding motor stops rotating.

5. Press PARAMETER SETTING in Fig to jump to this following display

The AUTO TIMING shown in Fig is to control the feeding motor. When press AUTO, the FEED DELAY/STOP DELAY will work; When press TIMING, the FEED TIME/STOP FEED TIME will work. This is specially designed for different powder, the time can be set, and the detail setting is as following:

A-With automatic operation, in AUTO, the time in FEED DELAY refers to how much time the feeding motor will continue to run when the powder level sensor inspects there is enough powder. With the running of the machine, the powder will be less and less. When there is no signal from the powder level sensor, the feeding motor will start to rotate immediately to feed in the powder until the powder level sensor inspects there is enough powder, then the feeding motor will still run as per the time in the FEED DELAY, after this the feeding motor will stop the feeding. The time in. STOP DELAY means when the feeding motor runs the set time, but still the powder level sensor still has no signal, so this indicates there is no powder in the hopper, so the machine will stop. At the same time, the display will jump to the alarm display picture in FIG 4 to give alarm to the operator to realize feeding control.

B-When machine is in auto operation in TIMING, the feeding is realized by circulatory control for the feeding motor as following:

The feeding motor runs the time in FEED TIME, then stop the time in STOP FEED TIME, run again the time in FEED TIME, then stop the time in STOP FEED TIME.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche