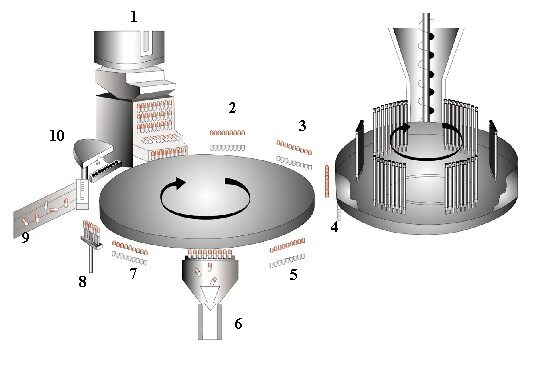

Automatic Capsule Filling Machine NJP Series Working Principle

Working Principle

NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly (quantity of die hole). It has 9 holes turning out a highest output of 1200 capsules/minute.

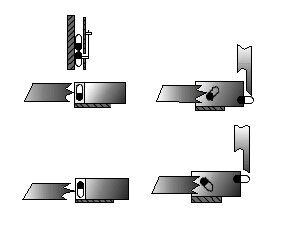

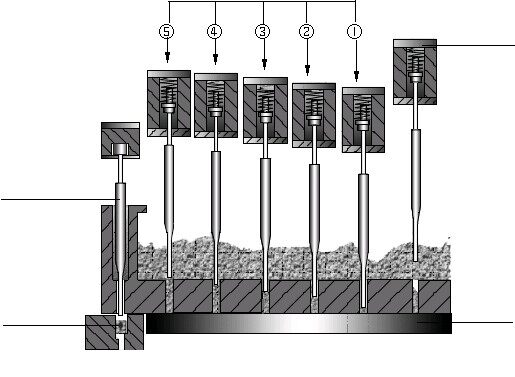

During the operation, the capsules in the charging hopper at the first station are fed through two hoppers vertically to capsule-feeding plate one by one. Then capsules are fed to the outside end of straightener by a horizontal fork and fed to the die assembly by vertical fork and pull of vacuum. Then split caps and bodies. At Station 2, the die assembly is lowered and moved outwards. At Station 3, pellet unit is installed for filling slow-released pellets. At Station 4, powder is filled (medicine powder is filled and pressed for five times and then fed into the body). Station 5 is left for station expansion. At Station 6, suction system cleans defect capsules (cap and body not split). At Station 7, the lower die assembly moves inwards and upwards simultaneously. At Station 8, locking pushrod moves upwards to join the filled capsules. At Station 9, the joined capsules are ejected and collected. At Station 10, the die holes are cleaned with dust collector to prepare for entering next cycle.

.jpg)

- Station 1: cap and body splitting

- Station 4: powder column filling

- Station 5: pellet and tablet filling

- Station 6: defect capsule cleaning

- Station 8: joining

- Station 9: lead-out of joined capsules

- Station 10: die hole cleaning

Air suction mechanism

The machine uses vacuum pump’s suction to open the empty capsule and uses dust cleaner to reject faulty capsule and clean mould.

Electric apparatus

The control system adopts the imported advanced & famous electric elements as the heart of this machine, with the tactile sensor as the operation panel and frequency conversion speed stepless adjust equipment, the machine is consummate and exquisite.

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche