Automatic capsule filling machine working principle

Automatic capsule filling machine can automatically finish capsule separation, filling and locking. So it can greatly improve production efficiency and reduce labor costs.

Automatic Capsule Filling Machine can be divided into intermittent motion machines and continuous motion machiens, and the intermittent motion type account for the majority of the market, so the following discussion will take this machine as example. The core part of the intermittent motion automatic capsule filling machine is the round filling stations in the center:

- Capsules rectification

- Separation of capsule caps from bodies

- Filling medication

- Wasted capsules rejection

- Capsule locking

- Filled capsuled ejection

- Cleaning

Read more:

What is Capsule Filling Machine

Best Capsule Filling Machine (Reviews & Guide)

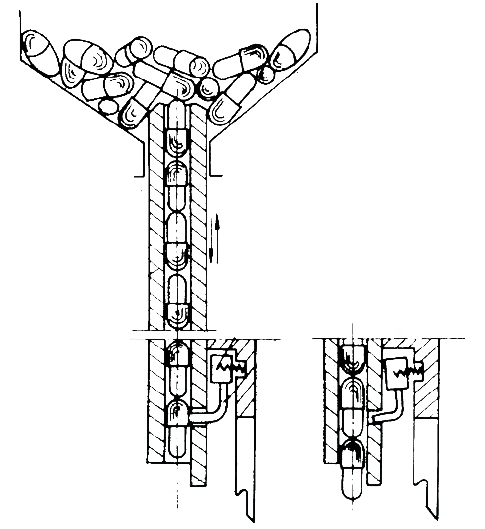

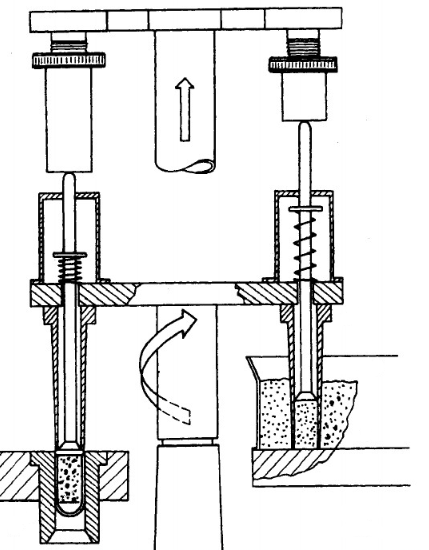

Capsules rectification

Most of factory-fresh empty capsules are joined capsules whose caps and bodies are joined together. Capsules need to be rectified for filling process. Capsules are randomly poured into the capsule delivery plate with a plurality of circular channels inside. These channels are suitable for a capsule to go through, and the lower part of each channel is equipped with spring pieces. During operation, the capsule delivery plate reciprocates up and down, and makes capsules enter holes and be stuck by the spring piece. Then the capsule delivery plate moves downward to make the spring piece releases the capsules, and then capsules falls. Capsules need further rectification as it may be body end downward or cap end downwards when falling.

The capsule falls in front of the horizontal fork. Due to the special structure, the horizontal fork always acts on the middle part of capsules bodies of which the diameter is smaller. Because of the different center of gravity, the capsule will be moved as the capsule body ahead, whether the capsule is capsule body end downward or cap end downwards. Then the capsule direction will be adjusted again by the vertical fork. So that all capsules enter the segment as capsule body downward. Now, the capsule rectification is completed.

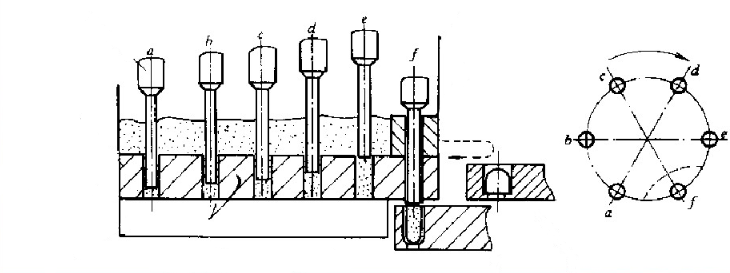

Generally, automatic capsule filling machine has different models available depending on holes on the capsule tray. Take our NJP series automatic capsule filling machine as an example: 6 holes for 9 holes for 1200C, 18 holes for 2000C, and 24 holes for 3500C. It shows how many capsules the machine can fill per time, and affect the maximum filling speed. Most automatic capsule filling machines can fill capsule of different sizes by changing mold.

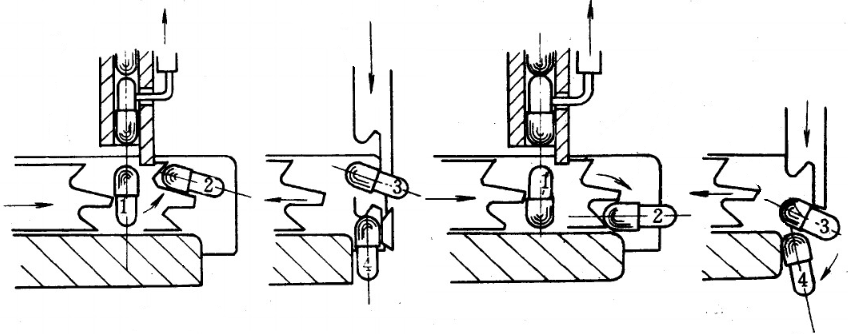

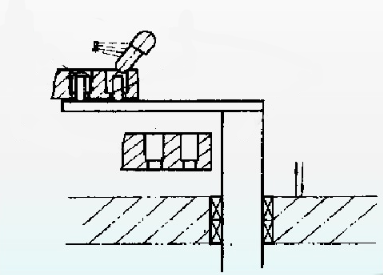

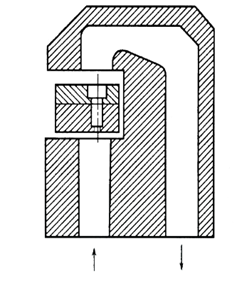

Separation of capsule caps from bodies

The capsule tray is transferred to the capsule separation station, and the vacuum divider raises to make its upper surface close to the lower surface of the lower segment without gap. The capsule will be separated by vacuum because of the difference of the diameter of capsule caps and bodies. Capsule caps will be stuck to the upper part of the capsule tray and capsule bodies will go downwards.

After separation, the upper and lower part of the capsule tray will be separated and be transferred to their respective stations.

Filling medications

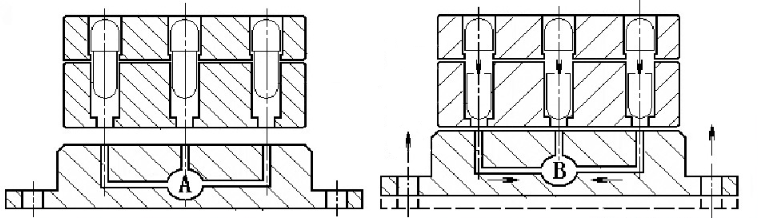

Capsule body will be conveyed to the filling station for filling medication. There are many ways of filling medication, mainly are the tamping filling and intermittent dosator filling.

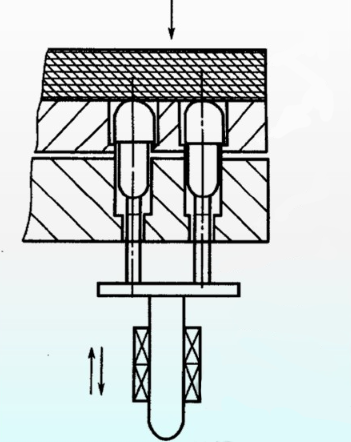

Tamping filling

Tamping pin capsule filling machine uses tamping punch to make powder compacted. The dosing disc will turn for once after taming to transfer the powder to next tamping punch and powder over the dosing disc will automatically fill the dosing disc holes. And after tamping, the powder will be filled into the capsule body.

With this method, the dosage is relatively accurate dosage, and the error is as low as 2%. And it is able to fine-tune the powder plug dose by adjusting the lifting height of the tamping punch. But this method is applicable to powder of good fluidity

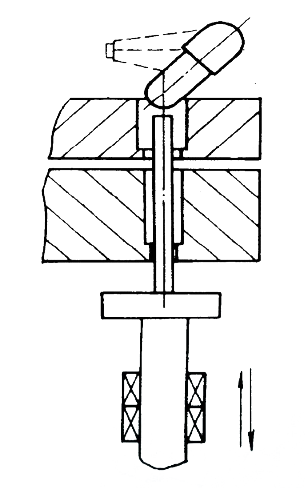

Intermittent dosator filling

Intermittent dosator filling method directly insert the empty dosage tube into the dosage hopper, and use the dosage punch inside the dosage tube to press powder. Then the dosage tube rotates for 180º. and press the powder plug into the capsule body to complete capsule filling.

This method could adjust the powder plug dose by adjusting the height of the powder in the dosage hopper and the stroke of the dosage punch inside the dosage. And the powder is required to have good fluidity. In addition, this method is time consuming, and it is better to adopt a continuous structure for capsule filling.

Wasted capsules rejection

A few empty capsules are not separated because of some reasons. There will be pins corresponding to the capsules. If the capsule cap is not separated from the capsule body, the pin will pull the capsule out of the mold, and the capsule will be blew to capsule collecting bags. The capsule caps and bodies that are separated will be transferred to the next station.

Capsule Locking

Upper and lower capsule tray rotate to the locking station at the same time, and at this moment, axis lines of the upper and lower capsule tray overlap. The baffle plate above the capsule tray and the pin below the tray begin to move to make capsule be locked.

Capsule Ejection

The capsule ejection device is similar to capsule rejection device, The pin will push the locked capsule out of the capsule tray, and then compressed air blows ejected capsules into the outlet.

Cleaning

Capsule tray will move back to the first station of capsule rectification after complete the whole filling process. But there could be powder or wasted capsule remaining in the capsule tray that need to be cleaned. Apply compressed air to blow the powder and wasted capsule into the dust collecting system form the bottom.

The above is the whole process of automatic capsule filling. Although it seems cumbersome, each step takes short time, and the reasonable circular structure makes these steps proceed simultaneously. So, with the highest speed, the automatic capsule filling machine can fill 12k-450k capsules per hour, and it is the best choice for large-volume capsule production. At iPharMachine, we offer a wide range of Encapsulators to meet various production needs.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche