Introduction

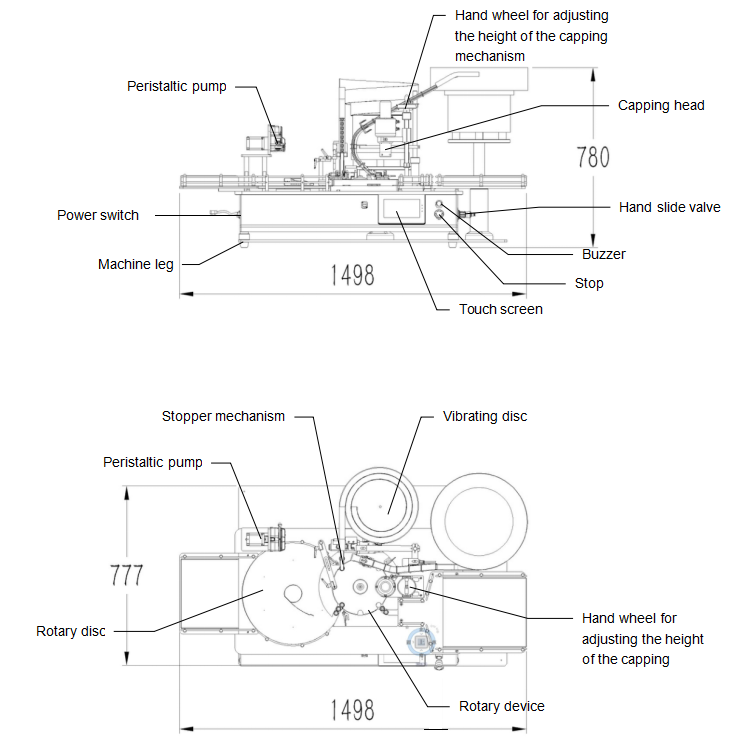

The fully automatic desktop vial filling and capping machine CGZ-20 is an automated equipment designed for the food, daily chemical, pharmaceutical and other industries. The equipment adopts a mechatronics design, with an advanced PLC programmable controller and a color touch screen control system, ensuring the ease of operation and stability of the process. The main work flow of the equipment includes bottle feeding, testing, capping, capping and bottle discharging, and it can complete these processes continuously, thereby improving production efficiency.

Simple display

In addition, the equipment has a production capacity of 15 to 20 bottles per minute (depending on the size of the bottle) and can be customized according to customer needs. The power requirement is 110V 50/60Hz single-phase power supply, the power is 500W, and a compressed air supply of 0.4 to 0.6MPa is required. The filling accuracy is ±0.5%, and it can be customized according to the bottle diameter and height to meet different needs.

Specifications

| Model | CGZ |

|---|---|

| Output | 15-20 bottles/minute (customizable based on bottle size) |

| Voltage and Power | 110V 50/60Hz Single Phase 500W |

| Compressed Air | 0.4~0.6MP |

| Filling Range | Based on the filling range of the pump head |

| Filling Accuracy | ±0.5% |

| Applicable Range | Customizable based on the diameter and height of the bottle |

Features

- Reasonable design, compact structure, suitable for fast capping, and high reliability.

- Simple operation, easy maintenance.

- The material contact part uses 316L stainless steel and high-purity ceramic pump, which has excellent acid and alkali resistance and corrosion resistance, and meets food hygiene standards.

- Different specifications of capping heads and turntables can be selected according to needs to adapt to bottles of different capacities.

- Easy to disassemble and clean, simplifying maintenance and maintenance work.

- The appearance is made of 304 stainless steel and aluminum, which is beautiful and generous.

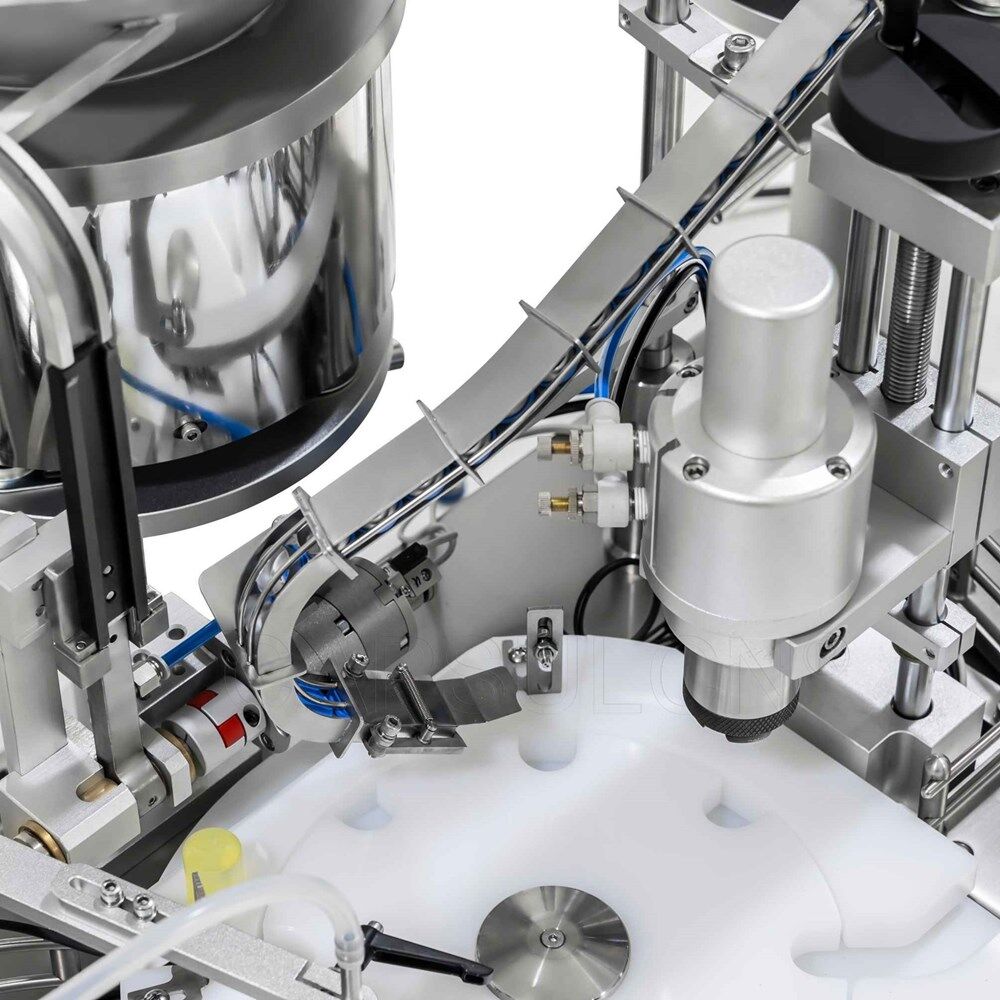

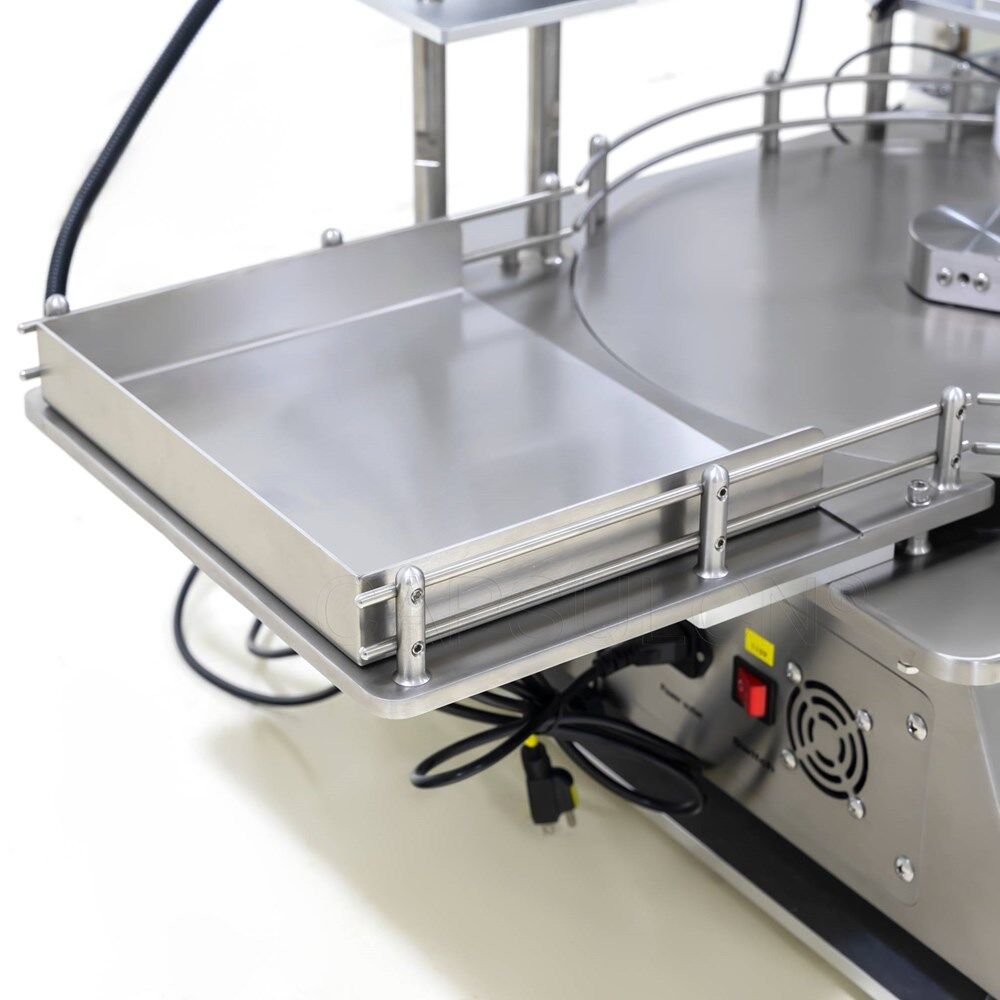

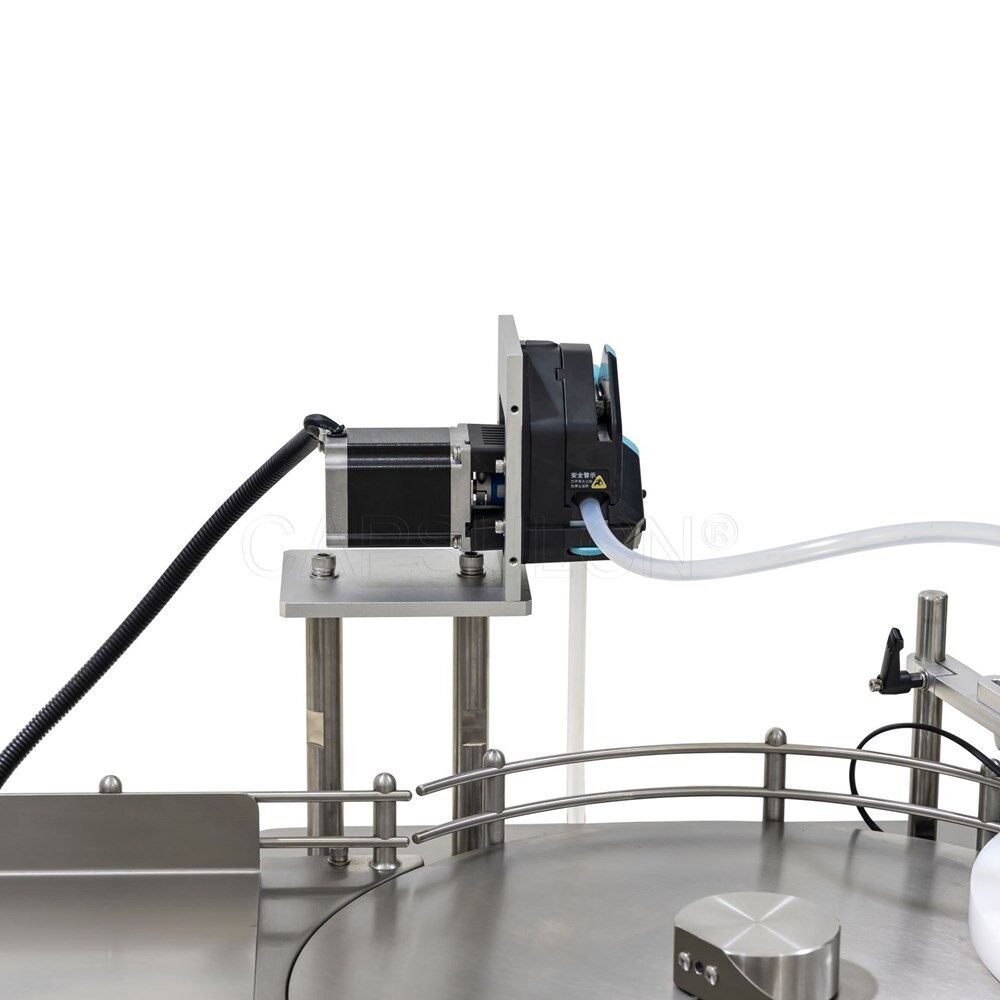

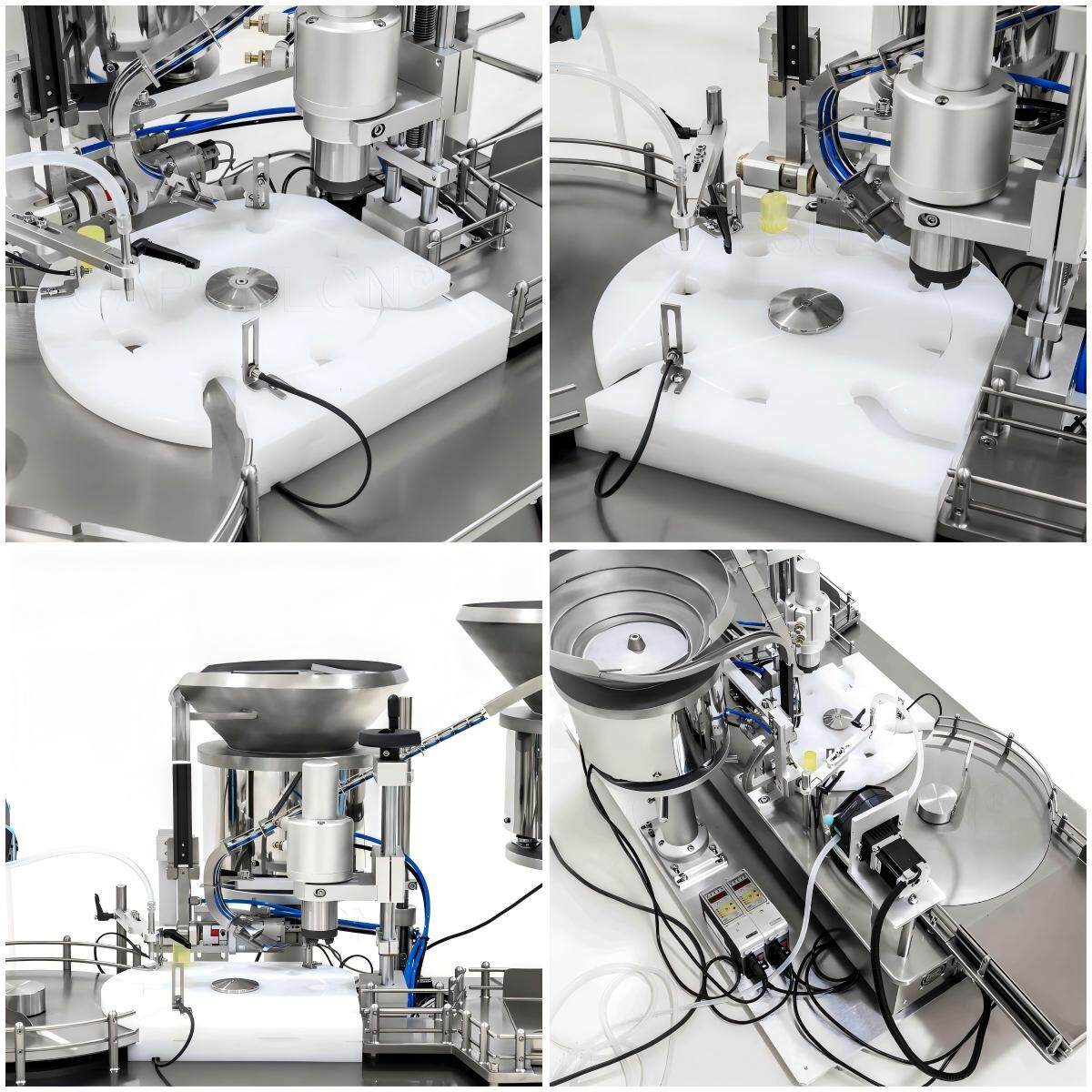

Detail image

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche