Video

Introduction

Automatic Capsule Liquid-Filling Machine

NJP-500 automatic capsule liquid-filling machine is by far the most advanced machine of its kind in international market. The machine has many strengths.

- High configuration. Reducer, vacuum pump, cam indexer, electrical components, the use of internationally renowned brand products.

- Quite stable performance. It has the advantages of good sealing, variable frequency stepless speed regulation, simple operation steps, good capsule loading effect, accurate filling, small volume, low energy consumption, high output, product standardization, serialization, low noise and small vibration. The main technical indicators are at the international level.

- Wide application. With corresponding molds, the machine can fill capsules from 00# to 5# and A- E safe capsules.

- The design of the fifth station is reserved for the expansion station in which the corresponding device is installed, which can be filled with slow-release pellets and tablets alone, or mixed with the liquid medicine in the same capsule. The machine can be optionally equipped with optical fiber sensors and high-speed panel-type micro-printers, which can be set to print automatically or manually; text descriptions of current output, cumulative output, cycle yield and yield can be provided at any time.

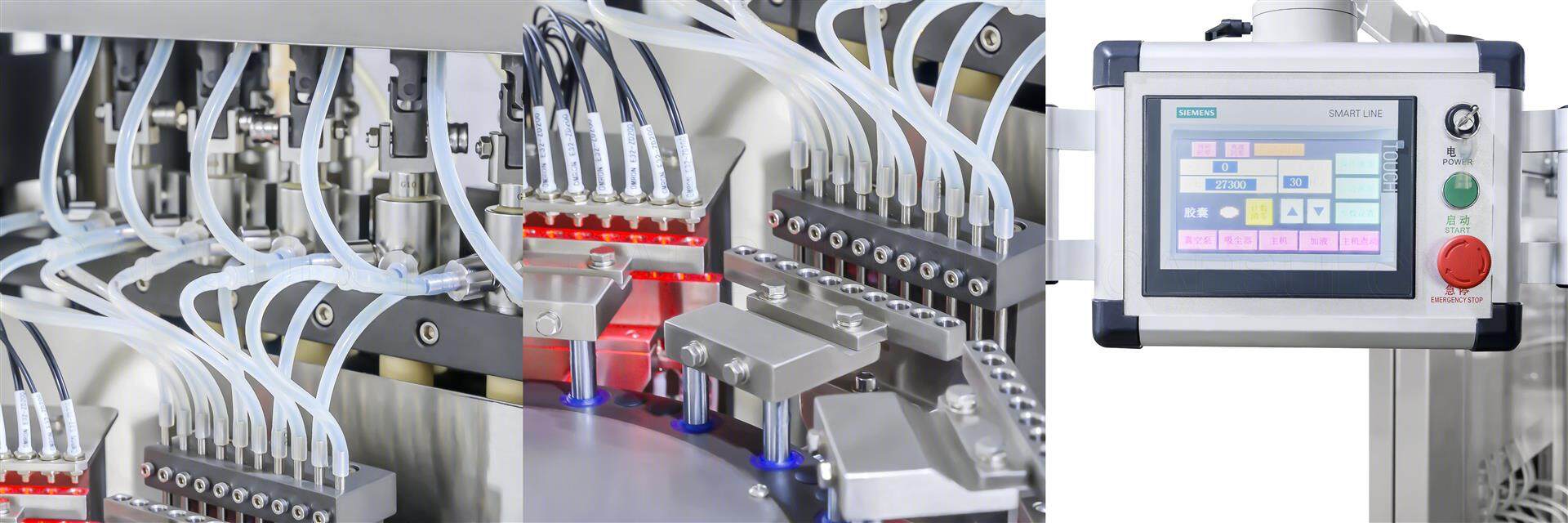

- Through the touch screen with alarm information, it prompts the working status of the main motor, vacuum pump, liquid stirring motor, door, etc., the capacity and position of the capsule hopper and the liquid hopper, the actual number of finished products, the yield, whether the capsule feeding channel is blocked, and whether the die hole is blocked. , whether the operator has any operating errors and other information.

Automatic hard capsule Liquid Filling & Sealing production line

Working Principle:The machine will automatically seal the capsules which have already been filled. The sealing solution contains Gelatin or HPMC. The sealing roller would apply solutions to the sealing part of capsules. Afterwards, the capsules would be conveyed to drying area with its sealing solution solidified by the air blown in so that the solution would not be stuck in the roller.

Features of the Machine:

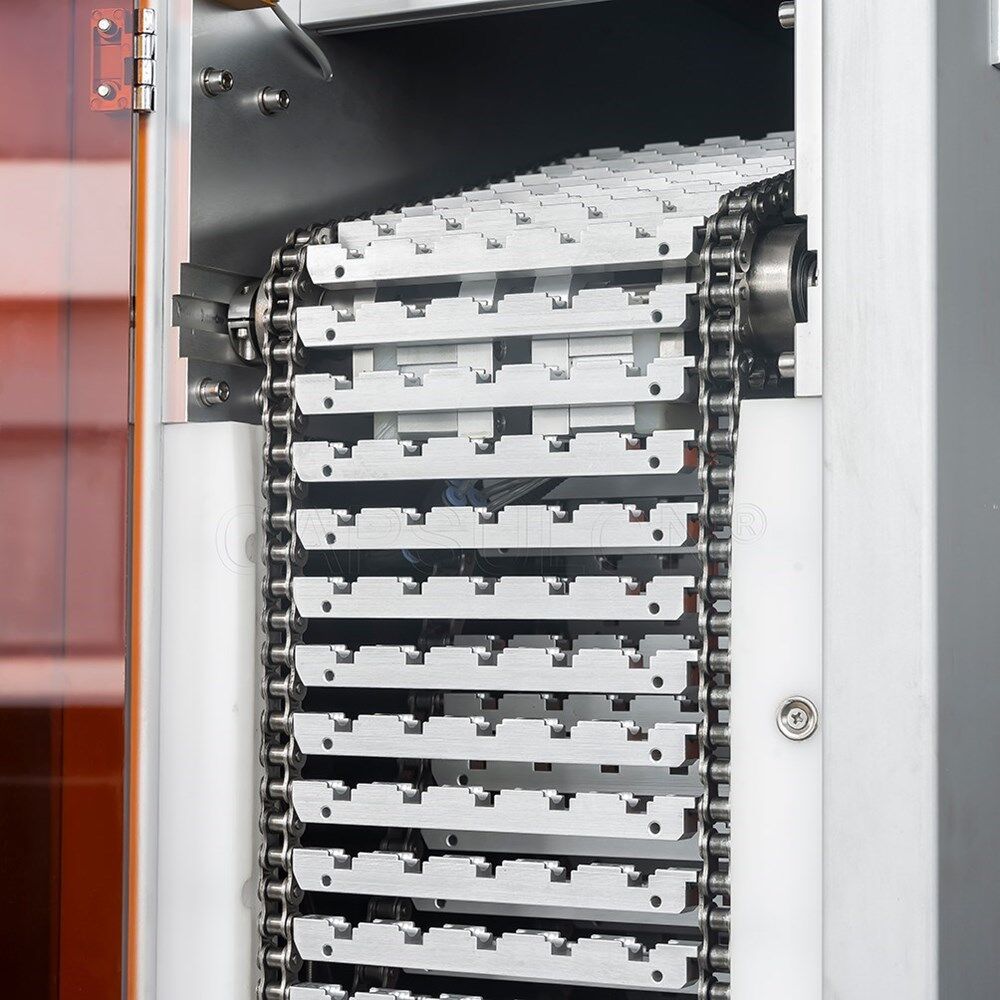

(1) Smooth Conveying

The machine adopts a position-rectifying mechanism with multiple rotary lines. Such mechanism avoids position diverting, wearing capsules and detachment of printing words, thus boosting the overall efficiency.

(2) Sealing Function

After capsules fill roller’s each hole, they will be conveyed to the transmission board plate within each hole. With the first sealing roller rotating, the capsule would be sealed. The second sealing roller would work the same, ensuring good sealing effect.

(3) Circulation of the Sealing Solution

The sealing solution would circulate between the sealing tank and the sealing box. When Gelatin is used for sealing, its temperature should be kept within the specified range. The state of the sealing fluid can be maintained by regularly adding sealing sol and hot water to the sealing tank.

(4) Drying

The sealed capsules are conveyed from the transmission plate to the drying unit where capsules can be dried until they are not sticky through the indoor filtered air.

(5) Capsule Size

The machine is available for capsules in different sizes through replacing relative spare parts. The capsules are from 000# to 5#

(6) Timely water-supplying function

This function can keep the concentration of the sealing solution constant by periodically adding hot water from the water supply tank to the sealing tank.

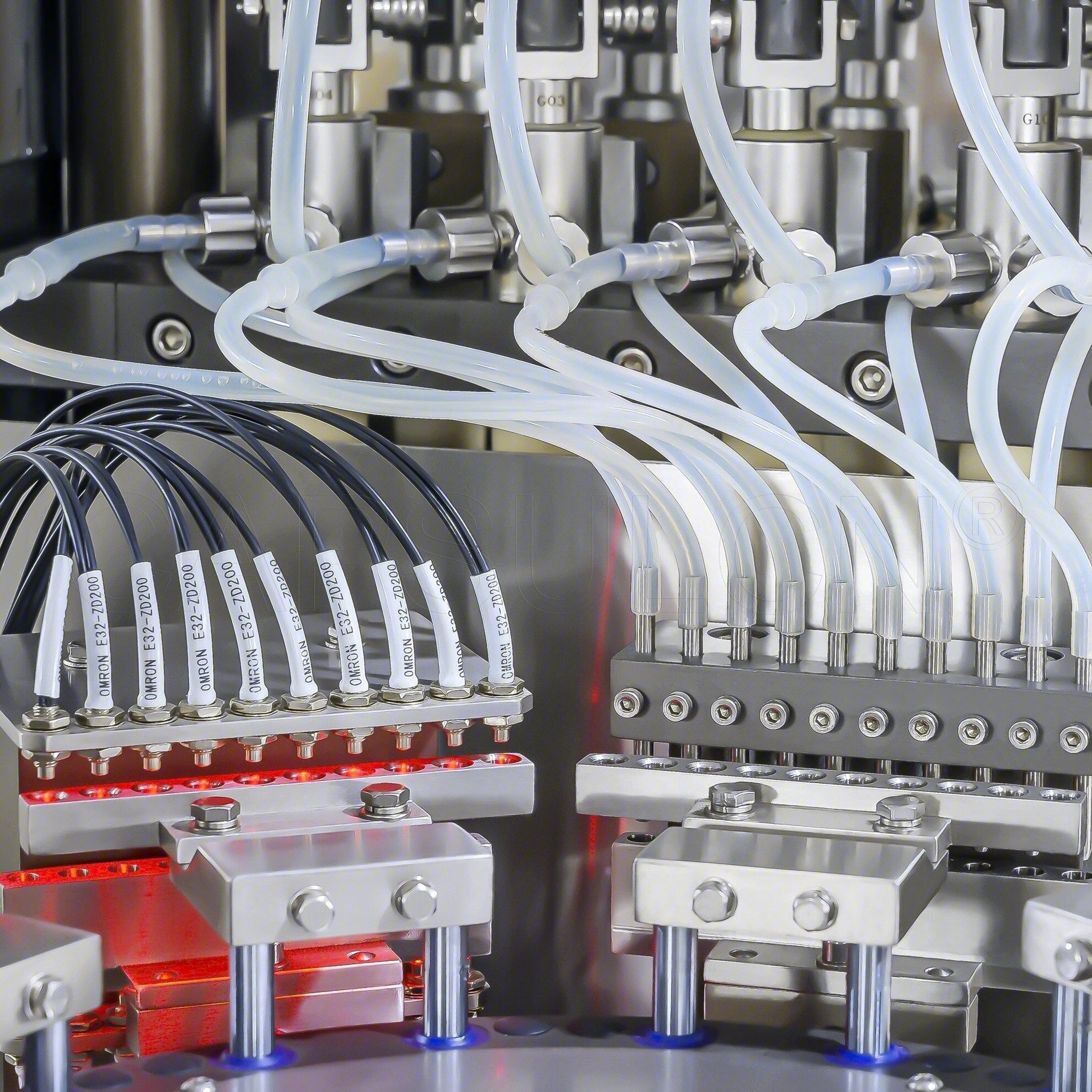

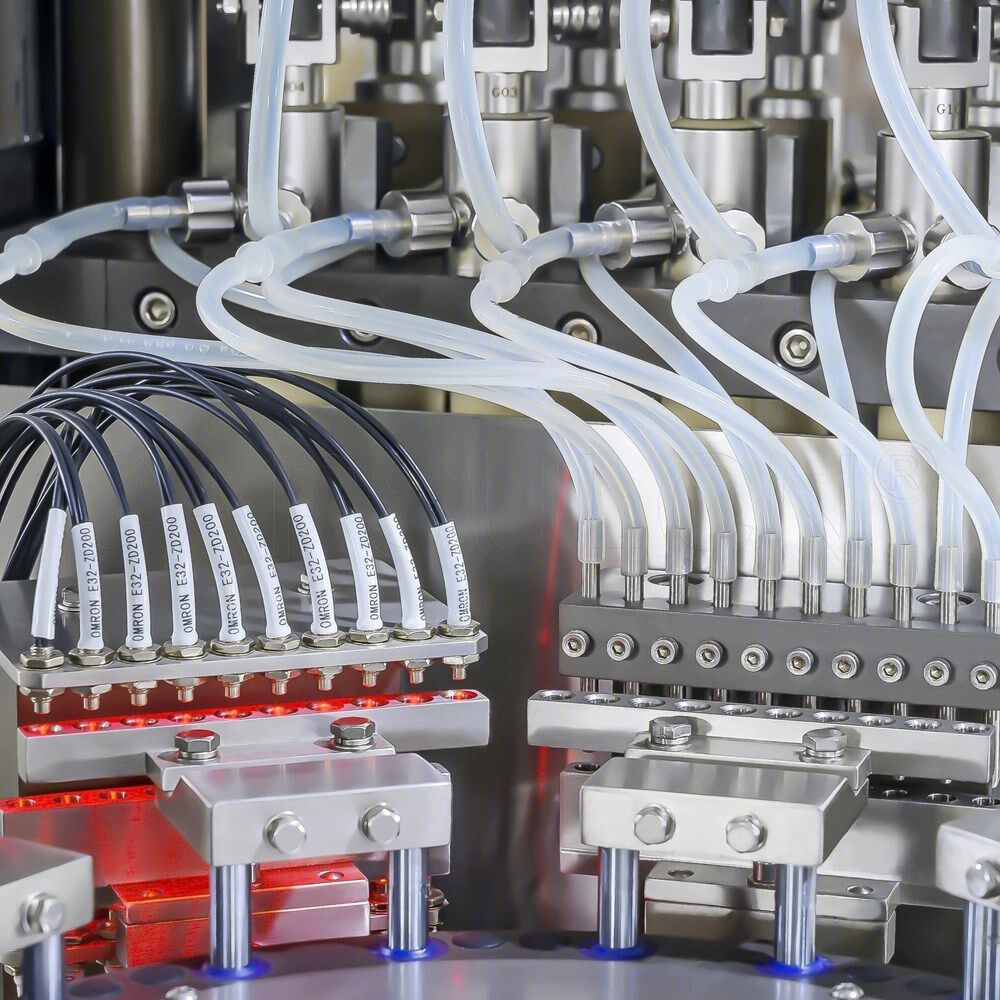

Detail Images

Specifications

| Machine | Liquid Filler NJP-500 | ||

|---|---|---|---|

| Suitable capsule size | 00#~5# | ||

| Capacity | 36,000pcs/hour | ||

| Power | 7.75kw | ||

| Power input | 380V 50Hz three-phase four-wire | ||

| Vacuum degree | -0.02~-0.06MPa | ||

| Water flow | 250L/h | ||

| Inner diameter of water inlet pipe | 15mm | ||

| Inner diameter of drain pipe | 20mm | ||

| Relative humidity | 40~55% | ||

| Temperature | 21℃±3℃ | ||

| Machine dimensions | 1335×1080×1900mm | ||

| Weight | 1000kg | ||

(Don't Worry! We have several Models. We can recommend you according to your requirement. )

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Automatic Capsule Filler & Encapsulation Machine NJP-1200C

Automatic Capsule Filling Machine NJP-3500C

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche