The Ultimate Guide to Buying An Automatic Tablet Counting Machine

The process of distributing drugs needs to be updated in the medical field. An automatic tablet counting machine is more of a technical fix for the issue. The machine uses a well-organized array of components to perform consistent and accurate counting.

With an automatic counting machine, counting pills, coated tablets, hard gelatin capsules, and softgels are simple. Additionally, it will spare you the trouble of counting and filling while enhancing efficiency using a dual nozzle design. This guide will help you choose an automatic counting machine that best suits you.

What is An Automatic Tablet Counting Machine?

You can count the pills or capsules you make with the help of an automatic tablet counting machine. Manually counting tablets and capsules can be difficult and time-consuming.

This might occur from having to spend the entire day standing still while counting the pills and capsules.

You can delegate all that work to an auto tablet counting machine. Counting and filling medications includes unique characteristics that work automatically.

The device counts all capsules without human intervention using a multitask vibrating mechanism.

What kind of products can an automatic tablet counting machine count?

This machine helps count all tablets, including coated and uncoated tablets and hard and soft gelatin capsules.

In addition to its application in the pharmaceutical and nutraceutical industries, this machine is crucial to the food business since it can count beans, chocolate balls, bubble gum, and candies for you.

What Are The Advantages of An Auto Tablet Counting Machine?

Now that you have understood what an auto tablet counting machine is from the definition, the following paragraphs will expand on the benefits of this automatic tablet counting machine.

Good and Optimal Performance

The automatic tablet counting machine's operation ensures that you will receive fantastic outcomes.

Since the counting method is highly accurate, you shouldn't anticipate any errors. This is one of the advantages of a good and optimal machine.

Improved Quality Control

Using the machine, you can lessen the chance of breaking the tablets or capsules. As a result, it improves the quality of the tablet or capsule that is finally counted.

Machines for pharmaceuticals should generally improve quality control, and an automatic counting machine is one of them.

Easy Maintainability

When it comes to maintenance, you will invest little time and money in an automatic counting machine.

It is simple to maintain because all you need to do is clean and grease it regularly.

Prevention of Contamination

The automatic tablet counting machine eliminates the risk of contamination, which raises the possibility of various illnesses that could endanger patients' lives.

As a result, in contemporary pharmacy, a tablet counter is an absolute necessity and the most economical and effective instrument.

This device counts the majority of tablets and operates with 100% efficiency using the Advanced Real-Time Image Processing concept.

Counting many things simultaneously, such as pills, capsules, and tablets, is another significant benefit

For this reason, "Bulk Counting" is permitted. As a result, in each cycle, you will have three to five times the total production.

Read More: 26 Benefits of Using Tablet Counting Machines

What Are The Parts of Automatic Tablet Counting Machines?

The parts of tablet counting machine are as follows. All contact parts are easy to clean and change over.

- Human-Machine Interface Touch Screen

Among the most essential components of a counting machine is an HMI (Human-Machine Interface) touchscreen. It offers operators an intuitive interface to monitor and control the tablet counting and filling process. Additionally, it sends out warning or alert signals whenever a mistake happens.

- Feeding Funnel

The tablet counting machine has a funnel as a filling nozzle. It directs the tablets counted to a bottle or other packing container. To release the tablets, the funnel lines up with the bottleneck finish. Depending on the needs, the funnel can be made of stainless steel or plastic. Depending on the bottle neck finish size, its mouth can be altered.

- Feed Hopper

A tablet counting machine has a hopper that holds and feeds the tablet to be counted into the device. The component is the starting point for the tablet counting procedure. An automatic loading device or a manual loader can be used to load the tablets into the hopper. The design of the hopper is vibration-feeding. Additionally, the design avoids bottlenecks and ensures a seamless flow of tablets to the subsequent level.

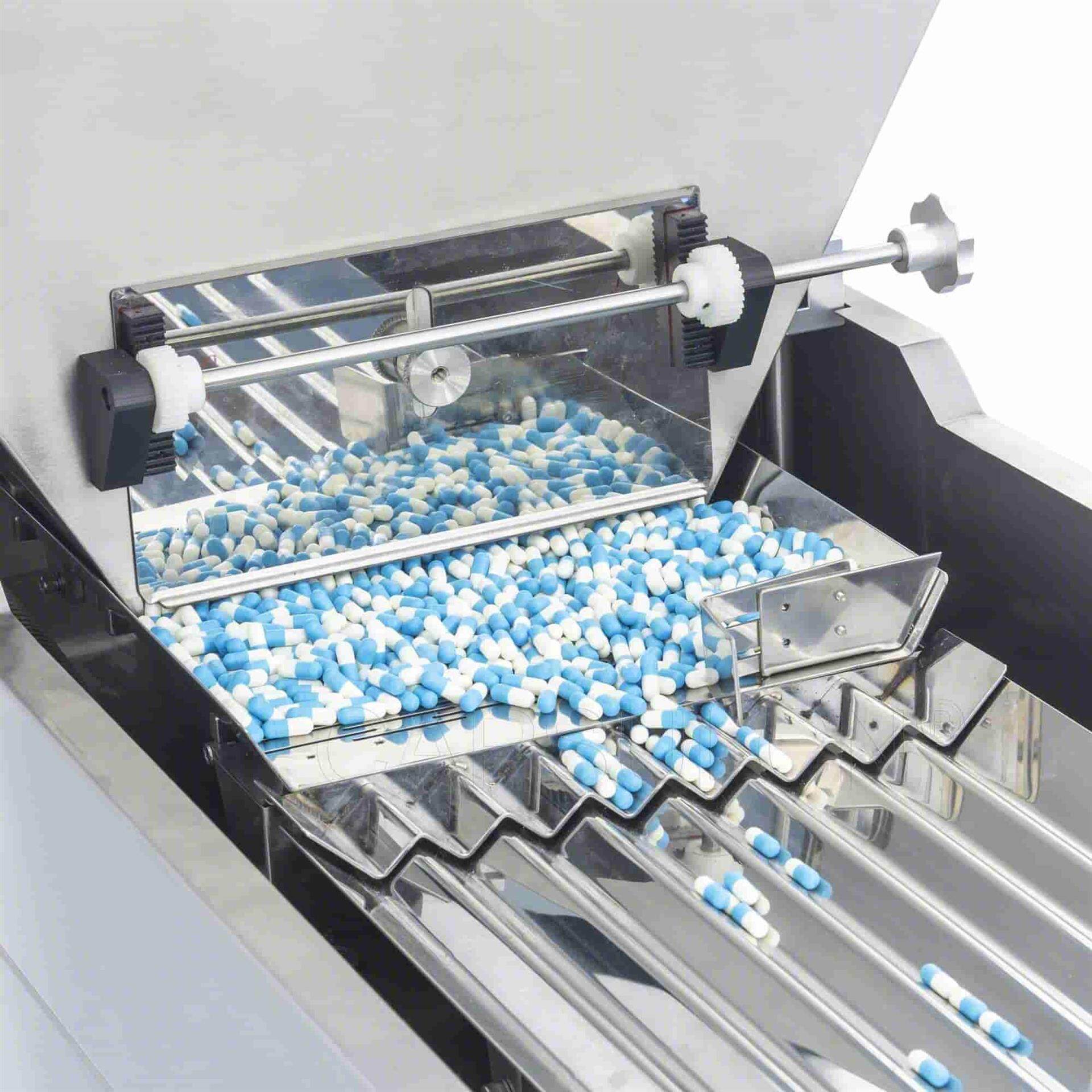

- Vibratory Plates

Vibratory plates are critical parts of automatic tablet counting machines. They typically have multiple channels to accommodate tablets running out of the feed hopper. These plates use a vibration system to keep the tablets organized and separated for accurate counting. Controlled vibrations transfer the tablets to the counting mechanism.

- Counting Sensor

The core components of a tablet counting machine are counting sensors. There is a row of square holes where these crucial parts are situated. These square holes align with the plate's channels and are located beneath the final vibratory plate. They are accustomed to collecting the fallen tablets and tallying them. This part guarantees precise tablet counting by "seeing" each tablet as it passes through the counting process.

- Electrical Enclosure

Every electrical part of a tablet counting machine is kept inside an electrical enclosure. It is responsible for shielding these parts from the elements and keeping operators safe from electrical risks. Often, you can lock the enclosure to stop unwanted access.

How Does The Automatic Tablet Counting Machine Operate?

Remember it was stated that one of the parts of an automatic table counting machine is the touch screen? With the touchscreen control system, you may modify the machine's operating time and pace to suit your needs.

Utilizing an automatic tablet filling machine simplifies your work by filling the tablets automatically after they have been loaded. Tablets are fed into the counting device using multi-channel vibratory plates. The channels guides the tablets automatically all along the way to the counting mechanism.

The machine is equipped with a range of sensors to detect the the level of tablets in the hopper. Infrared rays will count the tablets as they pass through the holes at the end of vibratory plate. The photoelectric sensors are also mounted along the conveyor belt to detect bottles.

Subsequently, the broken tablets are detected and rejected; the apparatus is engineered so that fractured tablets migrate to a different side from fine tablets. Once the tablets have been successfully counted, you can turn the machine off and clean it.

With these steps, you have successfully operated an automatic tablet counting machine. Thumbs up!

Besides, there is a blog post that specifically discusses the working principle of tablet counting machines. Hopefully, this post will provide enough information to help you understand how an automatic tablet counting machine works.

Things To Take Note Before Buying An Automatic Tablet Counting Machine

You need to consider a few things before rushing to get an automatic pill counter machine, automatic capsule counting machine, or automatic tablet counting machine.

Quality and Performance Compliance

Verify the machine's stability before using it; a slower, more reliable machine will be more beneficial to you than a quicker, less reliable one. Maintaining an unreliable machine will be a waste of effort and money. Every machine you plan to use must meet the required quality standards. Ensure any machine you plan to buy satisfies the required quality requirements. This is very important.

Production Capacity

Ensure you are aware of your activities' precise output capacity. As a result, choose a device that can accurately count the number of medications you manufacture. That is the reason you need to consult iPharmachine now for guidance.

Type of Drugs You Produce

There are tablet and capsule counting machines in the market. You will choose a tablet or capsule counting machine depending on the kind you produce.

If you are still trying to figure it out, contact a professional who deals with either or all of these machines - an automatic pill counter machine, an automatic capsule counting machine, or an automatic tablet counting machine.

Budget

Always seek the best deal; avoid cutting corners on quality instead, do your homework in advance, and then bargain for the lowest price with the original equipment manufacturer.

The kind of machine you choose to buy will depend on your operating budget. The automatic counting machine gets better the more money you have.

Conclusion

An automatic tablet counting machine has been a crucial component of the pharmaceutical industry since it makes it easier for pharma manufacturers to boost production efficiency and generate significant profits. The machine will therefore prove to be a wise investment for your company.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche