How to Choose the Best Label Applicator Machine in 2024

No matter what industry you're in, labeling has become a crucial and necessary part of the production process. Labels display important product information for branding and marketing. Can't all this information be directly printed on the packaging? Many people may ask. Of course, it can. But what if information changes are required or the packaging material is difficult to have the information printed on?

That's when you need labels. However, labeling by hand can be time-consuming. A label applicator machine would be an excellent addition to your production process. How do you find the perfect labeling machine for your business? This simple guide is meant for you.

Different Types of Label Applicator Machines and Their Advantages

Prior to looking for the best label applicator machine, it's better to understand what types are available in today's market. Labeling machines are classified into several types based on different factors. Here, we will skip the most common factor - the level of automation. Let's explore the machines using different label application methods.

1. Top & Bottom Labeling Machine

Top and bottom labeling machines, as the name suggests, apply labels to both the top and bottom surfaces of the packaging at the same time. They work well with flat packaging like jars, cans, boxes, and clamshells. These label applicator machines dispense and apply labels horizontally. They can also be used as a top or bottom label applicator to offer flexibility to meet different production needs.

Key Advantages:

- Efficiency: Affixes labels to both the top and bottom surfaces simultaneously.

- Handling Flat Packaging: Suitable for jars, cans, boxes, and clamshells with relatively flat surfaces.

- Flexibility: Available as top labelers and bottom labelers, providing flexibility based on specific needs.

- Automation: Often automated and integrated into existing production lines.

2. Side Labeling Machine

Side labeling machines are pretty straightforward. They stick labels onto the front, back, left, or right side of a product or packaging. These machines usually dispense labels in a vertical way. They work best with square and flat bottles, boxes, and cartons. These label applicator machines are versatile enough to handle both flat and curved surfaces.

Key Advantages:

- Versatility: Can label various sides (front, back, left, right) of a product.

- Customization: Adjustable to label one, two, or three sides of the product.

- Container Compatibility: Labels containers that stand upright, including square and flat bottles, boxes, and cartons.

- Automation: Often integrated into packaging lines as automated systems.

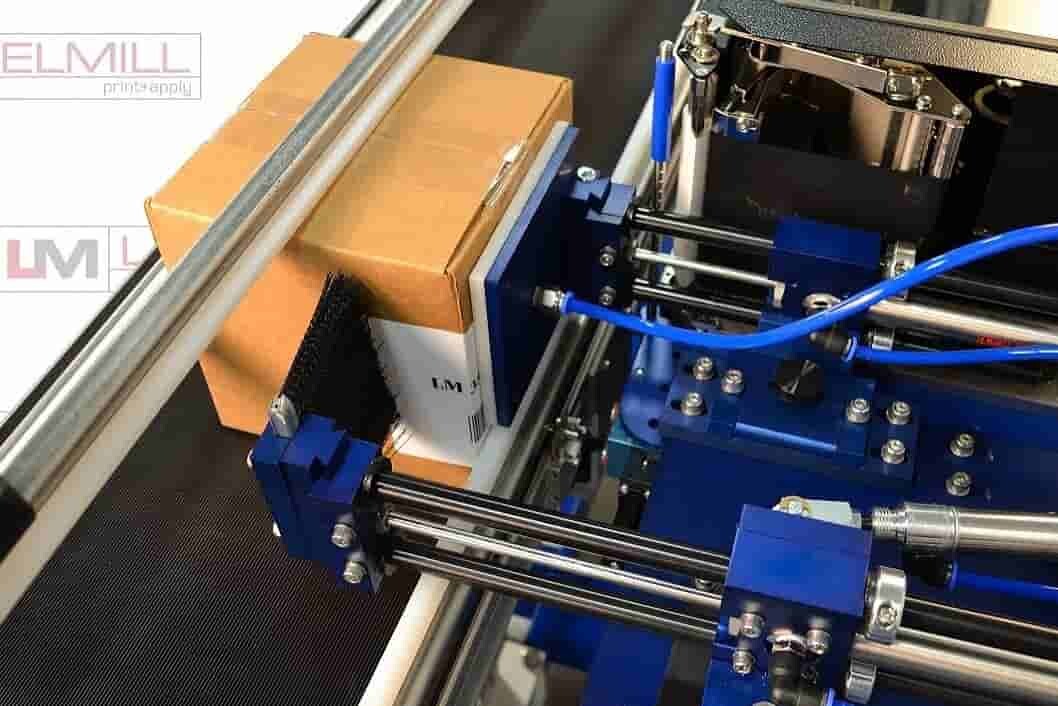

3. Corner Wrap Label Applicator

Corner wrap label applicators use a swing arm with a tamp pad to first apply part of the label to the front panel. Then, they wrap the rest around the corner and adjacent surface. Corner wrap label applicators are perfect for cartons and boxes that need tamper-evident labeling.

(Image Source: LabelMill)

Key Advantages:

- Specialized Tamper-Evident Labeling: Ideal for cartons and boxes requiring tamper-evident labels.

- Unique Application: Applies labels to adjacent panels using a swing arm with a tamp pad.

- Product Safety: Provides evidence of whether the product inside the packaging has been tampered with.

- Specialized Use: Designed specifically for tamper-evident labeling.

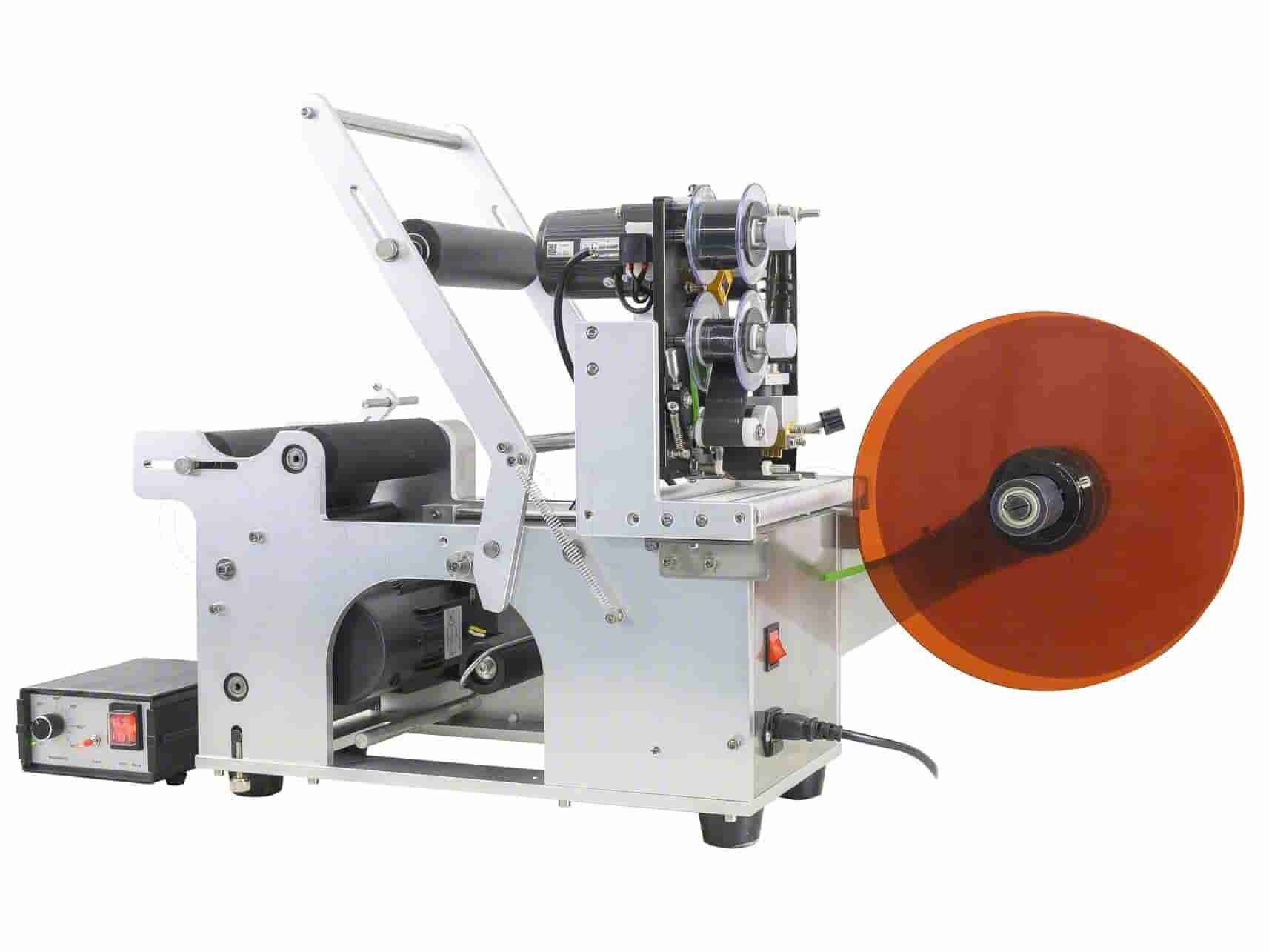

4. Wrap-around Labeling Machine

If you want to label round bottles, go for wrap-around labeling machines. This machine applies a label that offers 360-degree coverage to your product. Wrap-around label applicator machines are suited to cylindrical containers. They can also handle packaging materials like plastic, metal, and paperboard.

(Image Source: ALTECH)

Key Advantages:

- Ideal for Round Containers: Well-suited for handling round bottles and jars.

- 360-degree Coverage: Applies labels to the circumference of the product for complete coverage.

- Material Compatibility: Can work with a broad range of packaging materials, including plastic, glass, paperboard, and metal.

- Popularity: Widely used in the cylindrical container market.

Best Label Applicator Machines 2024

Choosing the best label applicator machine is more than just finding the most affordable model. Labeling machines widely vary in type and feature. We've rounded up our top picks for the best labeling machines of 2024.

Best Automatic Labeling Machine: PBTB-160

$14,966.00 / 3-Year Warranty

Specifications

— Labeling Speed: 120 bottles/min

— Container Size: 50-500 ml

— Label Size: Length 25-200 mm Width 25-90 mm

— Dimensions (L*W*H): 2000 × 1150 × 1650 (mm)

— Weight: 300 kg

Product Highlights

- Efficiently labels a diverse range of packaging formats

- Adjustable production volumes for versatile production planning

- User-friendly interface for ease of operation and simplified maintenance

- Advanced photoelectric sensors for precise printing and label feeding

- Incorporates robust safety measures for operator and machine protection

- Seamless integration into packaging lines for enhanced operational flow

- Manufactured in strict adherence to GMP standards

Best Flat Surface Labeling Machine: T30114

$2,231.00 / 3-Year Warranty

Specifications

— Labeling Speed: 15-30 pcs/min

— Labeling Accuracy: ±0.5 mm

— Flat Surface Size: Length 20-200 mm Width 20-150 mm Thickness 20-120 mm

— Label Size: Length 15-100 mm Width 15-110 mm

— Dimensions (L*W*H): 920 x 470 x 500 mm

— Weight: 41 kg

Product Highlights

² Comes in a durable build crafted from high-grade stainless steel and aluminum alloy

² Capable of manual and automatic labeling operations

² Features a PLC-controlled stepper motor for precise labeling

² Maintains consistent label web tension with a built-in brake

² Ensures accurate labeling with a deviation of ±0.5mm

² Boasts a customizable labeling head to handle flat and curved surfaces

² Uses the tamp-blow labeling technique

² Can integrate a print-and-apply system for more efficient labeling

Best Label Applicator Machine for Beginners: MT-50M

$969.00 / 3-Year Warranty

Specifications

— Labeling Speed: 20-50 bottles/min

— Labeling Accuracy: ±0.5 mm

— Bottle Diameter: Φ20-120mm

— Label Size: Length 30-280 mm Width 20-130 mm

— Dimensions (L*W*H): 670*370*520mm

— Weight: 29 kg

Product Highlights

- Crafted with 304 stainless steel and aluminum profile construction

- Capable of labeling bottles of various sizes for diverse applications

- Adopts hot stamp ribbon to eliminate concerns about ink contamination

- Can print on a variety of packing materials, including PP, PE, OPP, CPP, aluminum foil, and paper

- Adjustable photoelectric sensor sensitivity ensures accurate labeling

- Identifies label liners with different transmittance for optimal adjustments

- Rust-proof, pollution-free, and compliant with GMP standards for assured quality

What to Look for When Choosing the Best Label Applicator Machine

Choosing the best label applicator machine can be overwhelming. Here are some factors to consider when looking for your best fit.

1. Type of Labeling

Determine whether your needs lean towards side labeling, top & bottom labeling, wrap-around labeling, or a specialized solution like corner wrap labeling based on your product and packaging.

2. Packaging Shape and Size

Choose a label applicator machine based on the shape and size of your packaging (round, flat, square). Evaluate if the machine is capable of handling the surface of the packaging effectively, whether flat or curved.

3. Labeling Speed and Throughput

How many products are you going to label in one minute or hour? Determine your need for production volume before opting for a machine. This is because different label applicator machines feature different capacities and speeds.

4. Labeling Accuracy

The best label applicator machine can offer high accuracy of label application. Ask your potential supplier for a video demo of the machine in operation. Verify if the machine can label properly as required.

5. Automation and Integration

Label applicator machines are available in different degrees of automation. Determine the desired level of automation based on your production scale. Automated machines are often better options if you're looking for a perfect addition to your existing packaging line. Of course, they will cost you more.

6. Ease of Operation and Maintenance

The purpose of using a machine is to make work easier. Opt for a label applicator machine with a user-friendly control interface. Machine design also matters. Choose a well-designed machine that offers easy access to cleaning and maintenance.

7. Compatibility with Other Functions

A printing system is essential in the labeling process. It prints product information such as barcodes, use-by dates, batch numbers, and other details onto the labels. Even though most label applicator machines come with a print-and-apply system, it's better to make sure that the selected machine has such functionality.

8. Future Scalability

Think ahead! Do you need a label applicator machine that can handle your future business growth? If so, go for a scalable machine to meet increased production needs.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche