Top 4 Best Semi-Automatic Capsule Filling Machines

If you're reading this blog post, chances are you're looking for a better solution to enhance capsule-filling productivity. Let me guess - You might be struggling to keep up with today's high demand for dietary supplements. And you want to improve your production efficiency and output without compromising on quality. If so, it's time to invest in the best capsule filling machine.

Of course, you might feel overwhelmed when faced with too many options. Don't worry. This blog post will give you a tour of the best semi-automatic capsule filling machines on the market. And then, we will show you what to look for when choosing the right equipment. So, let's dive right in!

Let's take a look at the best semi-automatic capsule filling machines!

If you haven't a clue about what kind of equipment best suits you, let's introduce you to some models you shouldn't miss out on.

At iPharMachine, we offer an array of capsule filling machines, including manual, semi-automatic, and fully automatic models. Among them, the semi-automatic capsule filling machines have received a lot of good reviews from customers. Below are the best four iconic models that might be what you've been looking for. For your selection, we also include the details of semi-auto capsule filling machine parts, parameters, their highlights, as well as the videos of how semi-auto capsule filler works.

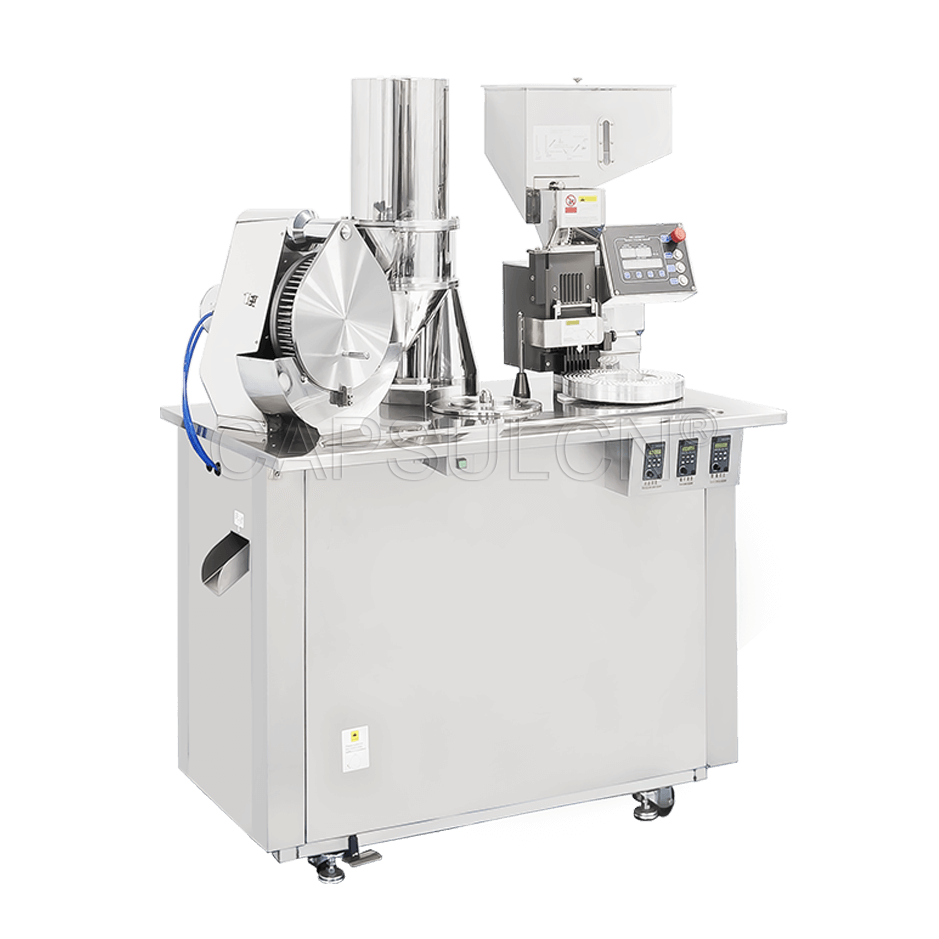

1. JTJ-V Vertical Type Semi-automatic Capsule Fller

Features:

- Variable frequency drive system for precise dosing

- Pedal-controlled capsule closing and locking

- Vertical peg ring for capsule closing

- Robust, high-quality stainless steel build

- All contact parts with GMP-compliant design

- Machine surface with a non-paint finish to avoid stripping and cross-contamination

- Simple design with minimal downtime

- Ease of operation and maintenance, low noise

Technical Data:

|

Model |

JTJ-V (Vertical Type) |

|

Production Capacity |

10,000-15,000 capsules per hour |

|

Applicable Capsule Size |

000#, 00#, 0#, 1#, 2#, 3#, 4#, 5# |

|

Fill Material |

Powders, pellets |

|

Total Power |

2.12 kW |

|

Compressed Air |

0.03 m3/min, 0.7MPa |

|

Vacuum |

40 m3/h |

|

Dimensions (L*W*H) |

1140 mm x 700 mm x 1630 mm |

|

Weight |

380 kg |

2. JTJ-V Horizontal Type Semi-automatic Capsule Filler

Features:

- PLC control system, HMI touchscreen

- Upgrade button-controlled capsule filling and closing

- Horizontal peg ring for capsule locking

- Automated capsule separation

- High-quality, hygienic stainless steel construction with cGMP-compliant design

- Simple design with minimal downtime

- Less labor intensive, easy to operate and maintain, super low noise

- 10-minute operator training

- Quick-changeover within 30 minutes for various filling formats

- Hard oxidized filling ring option

Technical Data:

|

Model |

JTJ-V (Horizontal Type) |

|

Production Capacity |

10,000-15,000 capsules per hour |

|

Applicable Capsule Size |

000#, 00#, 0#, 1#, 2#, 3#, 4#, 5# |

|

Fill Material |

Powders, pellets |

|

Total Power |

4 kW |

|

Compressed Air |

0.03 m3/min, 0.7MPa |

|

Vacuum |

40 m3/h |

|

Dimensions (L*W*H) |

1130 mm x 700 mm x 1600 mm |

|

Weight |

400 kg |

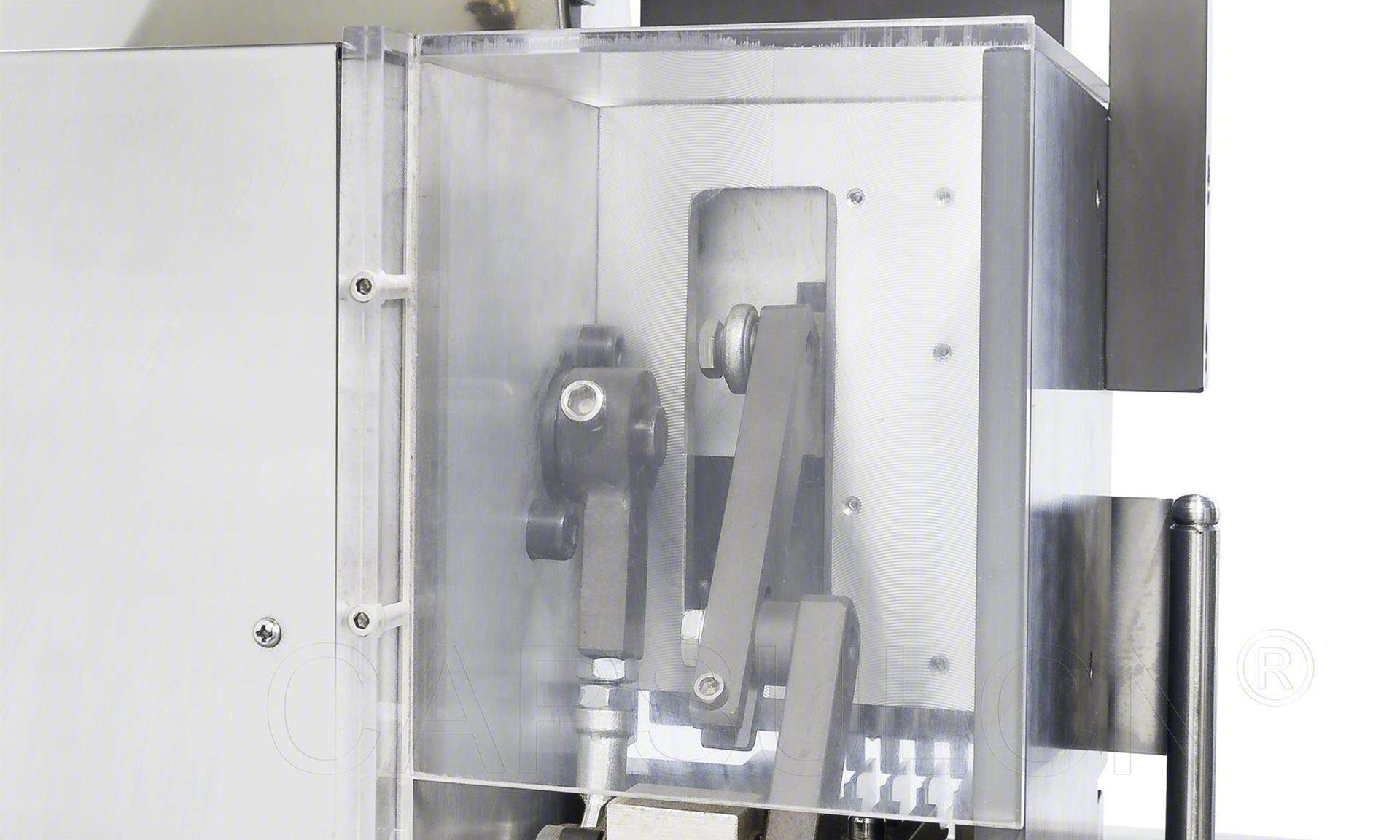

3. JTJ-V Pro Drawer Type Semi-automatic Capsule Filler

Features:

- Solid stainless steel construction

- External hex head screws for no chance of clogging or cross-contamination

- Hard oxidized filling ring for ease of cleaning and extra durability

- Main power switch for the immediate machine stop

- Easy access to the emergency stop button

- Drawer-type detachable discharge port for easy cleaning

- Reinforced tabletop with rounded corners

- 12-second capsule closing operation

- Double-head capsule feeding mechanism

Technical Data:

|

Model |

JTJ-V Pro (Drawer Type) |

|

Production Capacity |

42,000 capsules per hour |

|

Applicable Capsule Size |

00#, 0#, 1#, 2#, 3#, 4# |

|

Fill Material |

Powders, pellets |

|

Total Power |

4 kW |

|

Compressed Air |

0.03 m3/min, 0.7MPa |

|

Vacuum |

40 m3/h |

|

Dimensions (L*W*H) |

1140 mm x 700 mm x 1630 mm |

|

Weight |

400 kg |

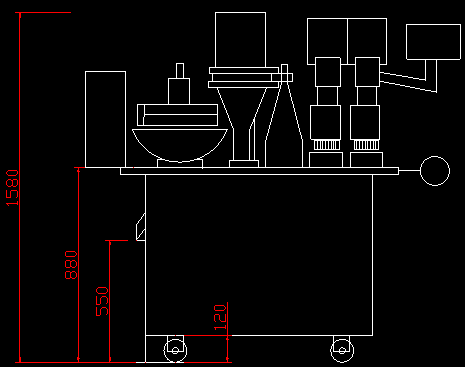

4. JTJ-V Pro+ Semi-automatic Capsule Fille

Features:

- cGMP-compliant design

- Dual loading system

- Quick-changeover within 15 minutes for various filling formats

- Hard oxidized filling ring with over 4-year lifespan

- Easy access to the main power switch and emergency stop button

- Horizontal capsule closing system without damaging capsules

- Rotatable discharge chute

- Hard oxidized tabletop with rounded corners

- Flexible swivel casters for easy movement of the equipment

Technical Data:

|

Model |

JTJ-V Pro+ |

|

Production Capacity |

30,000-50,000 capsules per hour |

|

Applicable Capsule Size |

000#, 00#, 0#, 1#, 2#, 3#, 4#, 5# |

|

Fill Material |

Powders, pellets, granules |

|

Total Power |

4 kW |

|

Compressed Air |

0.03 m3/min, 0.7MPa |

|

Vacuum |

40 m3/h |

|

Dimensions (L*W*H) |

1140 mm x 700 mm x 1630 mm |

|

Weight |

380 kg |

Factors to consider when choosing the best semi-automatic capsule filling machine

There are many common considerations, such as capsule sizes, production capacity, ease of operation, maintenance, filling accuracy, flexibility, and cost, for picking the right equipment for your product needs.

Since most semi-automatic capsule filling machines are designed with these considerations in mind, in this article, we'd like to share with you some factors that might be overlooked.

1. Compatibility with fill materials

Not every machine can handle various materials at the same time. If you're using a liquid material to fill capsules, you need to ensure that the machine can handle the viscosity of that liquid without causing it to leak or spill. In addition, If the material is too dense, it may not fill the capsule evenly.

So, make sure the machine is compatible with your fill material. This ensures the filling process is accurate and efficient without waste or contamination.

2. Integration with other equipment

Integrating a semi-automatic capsule filling machine with other equipment allows for a more streamlined manufacturing process.

If you plan to integrate your semi-automatic capsule filling machine with a conveyor belt or a packaging machine, make ensure that the machine design fits well with other equipment.

3. Safety features

Since semi-automatic capsule filling machines need manual intervention, safety is a priority when selecting a machine. Here are some safety features you should keep in mind: guards, sensors, and certification.

Guards prevent access to moving parts. This helps keep operators safe while the machine is in operation.

Sensors can detect when something goes wrong. They can trigger automatic shut-offs to prevent accidents or injuries.

A semi-automatic capsule filling machine certified by organizations like CE or UL meets safety standards for manufacturing environments.

4. Customization options

Customization is an important factor to consider when choosing a machine if you have unique production requirements that aren't met by standard machines. When considering these options, working with experienced semi-automatic capsule filler manufacturers in capsule filling is important. They can provide tailored solutions that meet your specific needs.

5. Footprint

The footprint refers to the space the machine occupies on your shop floor. So, before making the purchase, check the specifications for the machine dimensions to ensure it will fit in your facility.

In addition to the semi-automatic capsule filling machine, you may need other equipment, such as a conveyor or a packaging machine, to complete the manufacturing process. Make sure your facility has enough space to accommodate all the equipment.

Further, make sure there is enough space around the machine. This allows for easy access to cleaning, maintenance, and repairs.

6. Service and support

The best semi-automatic capsule filling machine should also come with comprehensive service and support. They should include on-site training, technical support, maintenance, repairs, and any necessary upgrades to the machine. Look for a manufacturer that is responsive and easy to work with.

7. Warranty and reputation

The manufacturer's warranty is also very important when choosing the best equipment. The warranty stands for the manufacturer's promise to cover problems with your machine. Moreover, make sure to ask about the reputation of the manufacturer you plan to work with. Check the customer feedback on the machine and the manufacturer.

8. Environmental impact

Environmental impact is a hot topic these days. The best capsule filling machine consumes less energy to operate, uses eco-friendly materials, and reduces its carbon footprint. Selecting a machine that is designed to lower its environmental impact is a practical way to give back to society.

Final Word

The above considerations will help you navigate the best semi-automatic capsule filling machine. But honestly, the quickest way to choose the best equipment is to work with a reliable manufacturer or supplier. As a professional capsule filling solution provider with nearly 30 years of industry experience, iPharMachine is here to help.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche