Introduction

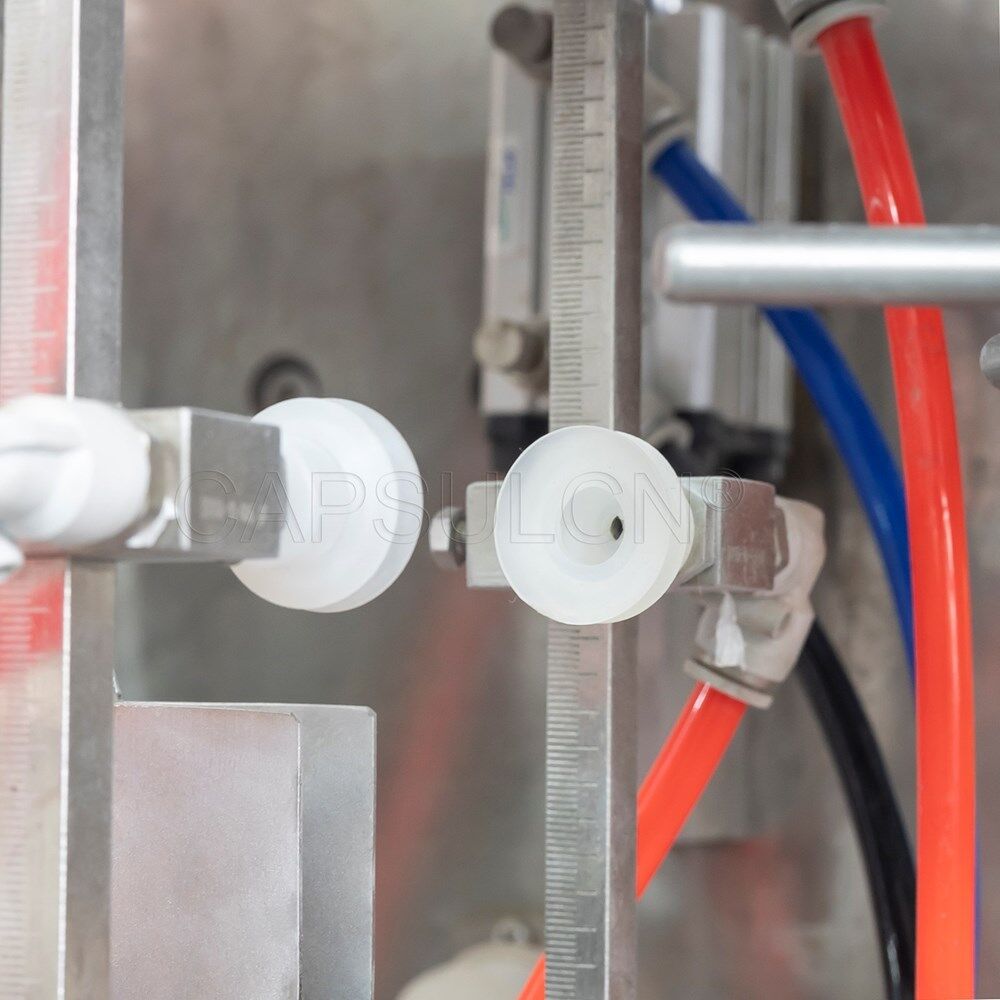

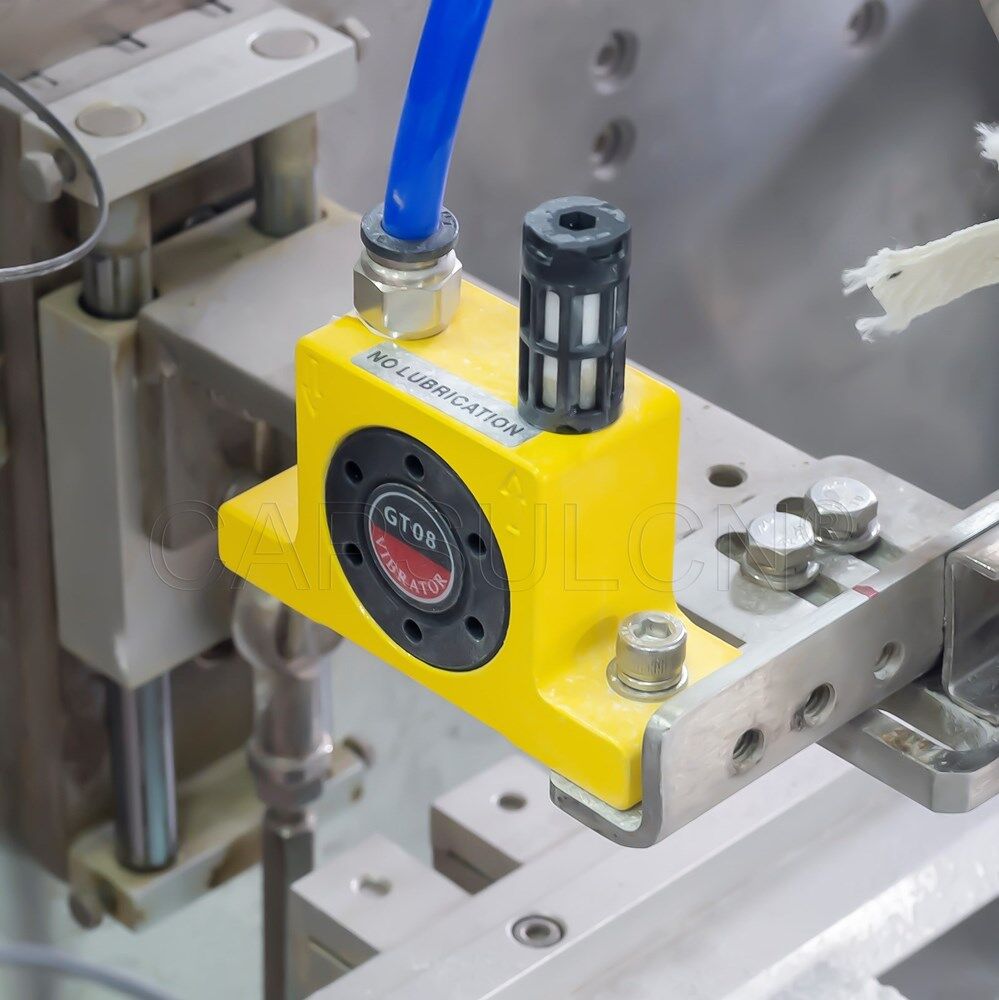

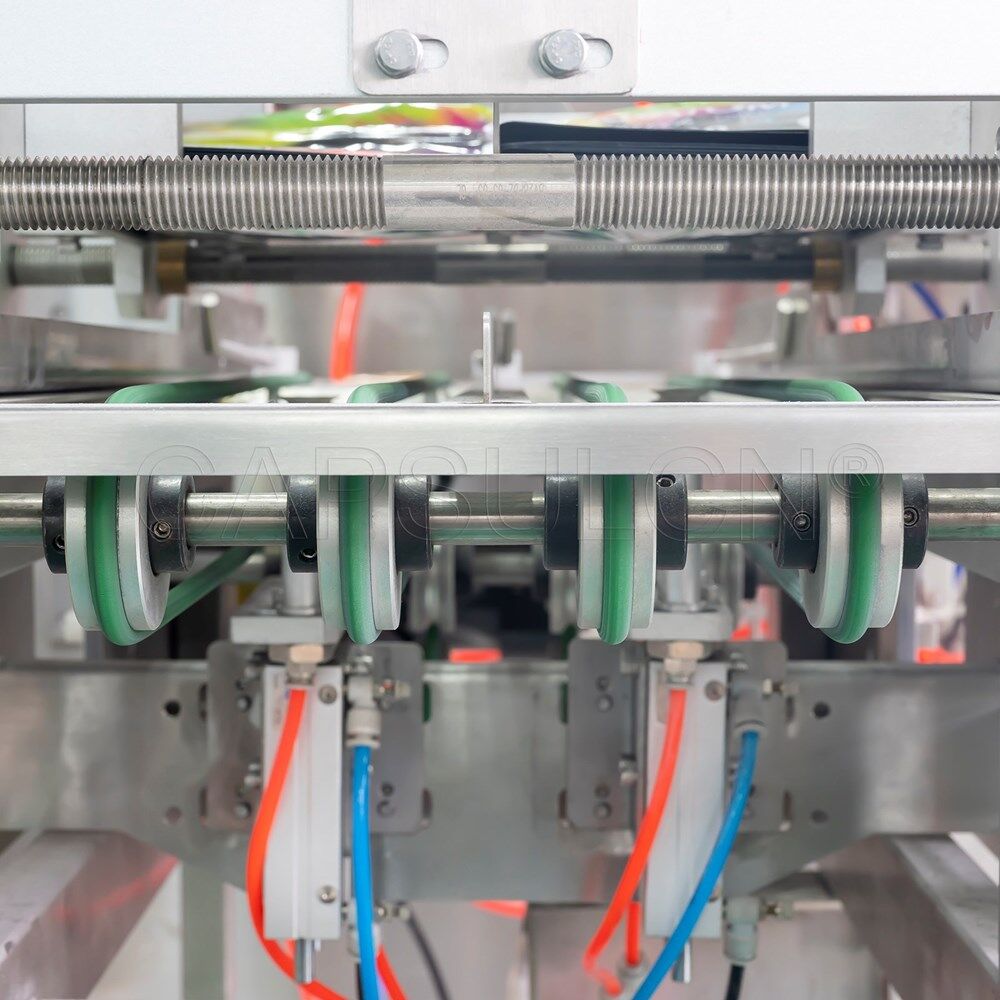

BHP-280D is a highly integrated machine, consisting of three parts: mechanical device, electronic control system and pneumatic control system. The mechanical device completes some mechanical actions under the synergy of electricity and gas, such as sealing, filling, bag transport, bag opening, bag unfolding and other actions. The electronic control system consists of multiple electrical components, including main motor, frequency converter, servo motor, servo driver, transformer, heating device, PLC, touch screen, photoelectric sensor, encoder and proximity switch. The pneumatic control system mainly controls and drives certain actuators to complete actions to simplify the mechanical structure. The machine has high integration of electrical components, strong control capabilities, and the use of touch screen technology is convenient and reliable. Pneumatic components have high reliability and stable operation. It is recommended to use dried compressed air to ensure the service life of the components.

Specifications

| Model | BHP-280D |

|---|---|

| Maximum Bag Size | 140 mm(width)×250 mm(height) |

| Minimum Bag Size | 90 mm(width)×110 mm(height) |

| Maximum Filling Volume |

600 ml |

| Maximum Packing Speed* | 100 kit/min |

| Net Weight | 2150㎏ |

| Relative Humidity | ≤85% |

| Voltage | 380(±7%) 50HZ VAC(Three-phase five-wire power supply) |

| Air Pressure | 0.6 MPa |

| Gas Consumption | 0.25 m3/min |

Packaging Principle

On the main shaft of the main shaft transmission device, there are a series of cams with different shapes. When the main shaft rotates, the action of each cam drives the corresponding device to complete the corresponding action; at the same time, when the cam rotates, the angle of rotation is transmitted to the PLC by the encoder connected to the main shaft, and the PLC controls the corresponding device to complete the corresponding action according to the set phase angle of the corresponding action.That is, the main shaft cam and PLC work together to ensure the coordination and unity of the actions of each device. Every time the main shaft rotates, the whole machine completes a complete bag-taking, filling, sealing and bag-out process

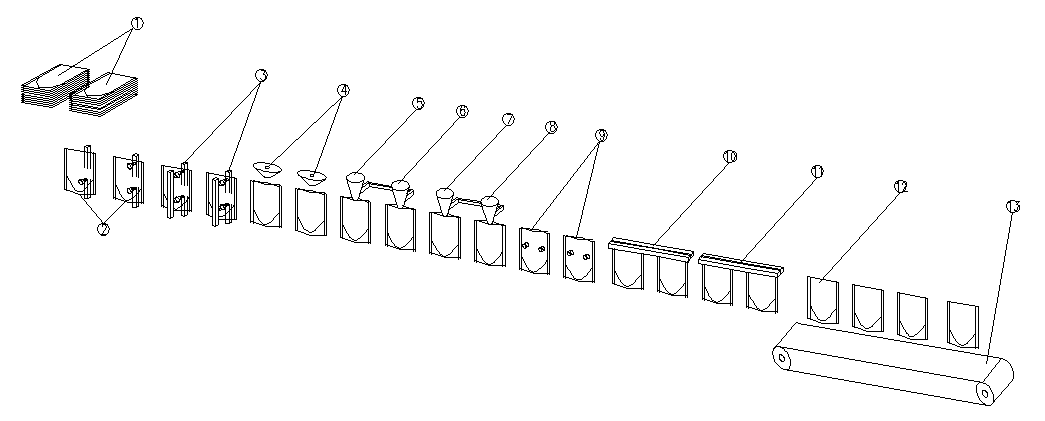

This machine automatically completes the packaging process of bag feeding, taking, opening, opening detection, filling, unfolding, sealing, output, etc., as shown in Figure 3-3. The process flow can be subdivided into

1bag feeding→2bag taking→3bag opening→4bag opening detection→5filling6filling→7filling8filling→9bag unfolding→10sealing→11seal cooling→12output13output

Remark

- Regularly clean the machine according to the nature of the product packaged by the user.

- Use a fine wire brush to clean the surface of the heat sealing block at any time to keep the surface of the sealing block clean.

- The horizontal and vertical sealing joint shaft and other rotating shafts should be kept clean for once a day.

- The scissors of the packaging machine are made of special alloy materials, which have the advantage of good sharpness. In order to maintain its sharpness and durability, the following points should be paid attention to in use:

(1)Keep the surface of the scissors clean and remove debris every day; apply anti-rust oil on the surface of the scissors after shutdown.

(2)Empty carts should be driven as little as possible to prevent the service life of scissors from being shortened due to idling in use.

(3)The abrasion of the blades of the scissors will cause uneven cuts in the bag. At this time, do not change the cutting angle at will. Use fine oil stone and lubricating oil to grind up and down along the pair of opposed friction surfaces of the scissors until they are sharp. - Check the coincidence of each pair of sealing blocks frequently and adjust if necessary.

- Discharge the sewage from the compressed air filter regularly, as shown in Figure 5-3, turn off the knob on the sewage outlet, drain the sewage into the prepared container, and then turn on the knob on the sewage outlet.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche