Blister Packaging Machine Working Principle - How Is Blister Packaging Made Step By Step

Blister packaging is a widely used packaging form. For different blister packaging, the blister, cavity, and box are different, as well as the shape, it will be different based on different products to be packed. Also, there are various substrates, materials and heat-sealing method for blister packaging.

You can find more information in “What Is Blister Packaging - Different Types Of Blister Packaging”, if you are interested in the blister packaging. The following will discuss the Working Principle of blister packaging. Although there are some differences in details, it shows a general process of the blister packaging:

- Unwinding

- Film forming (drum type / flat type)

- Filling products

- Heat-sealing (drum type / flat type)

- Trimming, printing, and rejecting scrap

The plastic film, such as PCV, on the uncoiler is conveyed forward, heated with a suitable temperature, and then smooth blisters are formed on the soften plastic film. Then, the PVC blister will be filled with materials, and meanwhile, the PVC blister will be pressed into the mold to be check the formed blister and the filled material. After that, the aluminum foil and the PVC are heat-sealed together. If necessary, the batch number and date, etc. can be printed on the back side of the aluminum foil. Finally, the blister is cut based on the request, and the waste products are removed according to the signals stored in the memory device.

In the above process, among machines, the biggest difference is based on blister forming device and the heat-sealing device. The blister forming is divided into drum type and flat-plate type. Flat-plate type of blister forming device generally performs better than the drum type. Heat-sealing is also divided into drum type and a flat-plate type. Regarding the heat-sealing effect, the flat-plate type is better than drum type, while drum type has advantages in speed and reliability.

The above process can be completed by manual operation, semi-automatic operation or automatic operation. For large production volume of blister packaging, relatively fixed variety, and the demand for safe and sanitary, it is advisable to use automatic packaging line for production. In addition, automatic blister packaging machine can be connected with automatic printing machine, manual inserting machine, boxing machine and others for a fully automated blister packaging line, to save labor and time.

We will introduce the Working Principle of the automatic blister machine with an example of aluminum-plastic packaging. These contents may help us know How Is Blister Packaging Made.

Unwinding

PVC plastic and aluminum foil need to be put on the foil coiler, and there will be difference in the operation and the way of placing the film. Generally, driven by the motor, the bearing rotates and take the clamped film to the forming station by guiding roller and positioning roller.

Film forming

Owing to the thermoplasticity of the plastic film, the PVC can be shaped as request when it is transferred to the forming mold. The heating temperature shall be adjusted according to the PVC, and for the rigid PVC the temperature needs to be 110-130 Celsius. The temperature of the heating element is much higher than that.

The heating method is divided into radiant heating and conduction heating. The conversion rate of radiant heating is higher. Most of the thermoplastic packaging can absorb the energy of 3.0-3.5μm wavelength infrared ray Therefore, it is better to use radiant heating method to heat the PVC. For conductive heating, also known as contact heating, the PVC will directly contact the heating source, the heating roller or the heating plate.

The PVC needs to be molded into a required shape after heated. The forming process is the most important part of blister packaging, and usually there are several forming methods as followings:

Blister forming: also known as negative pressure forming, there are vent holes at the bottom of the mold, and the softened PVC is sucked into the mold by vacuuming for forming. Usually the mold are rollers, and the finished blister is with small size, a simple shape, an uneven overall stretch, and a thin top.

Blow molding: also known as positive pressure forming, compressed air is used to blow PVC into the mold from above. Contrary to blister forming, this type of molding generally uses a plate mold, and the formed blisters are with more uniform wall thickness and a larger size.

Punch-assisted blow molding: the softened PVC is compacted with a punch, and then compressed air is introduced to make the PVC fit with the mold. This type of method is similar to blow molding, the blister edges are more distinct and can be used for making more complex blister. However, the punch needs to be designed well, and the pushing speed and distance need to be well calculated.

Cold stamping of convex and concave molds: no heating needed, and two corresponding concave and convex molds are used for direct cold forming. And there are holds in a bottom of the mold for discharging extra air. This is generally used for some of the more rigid special packaging materials.

Filling products

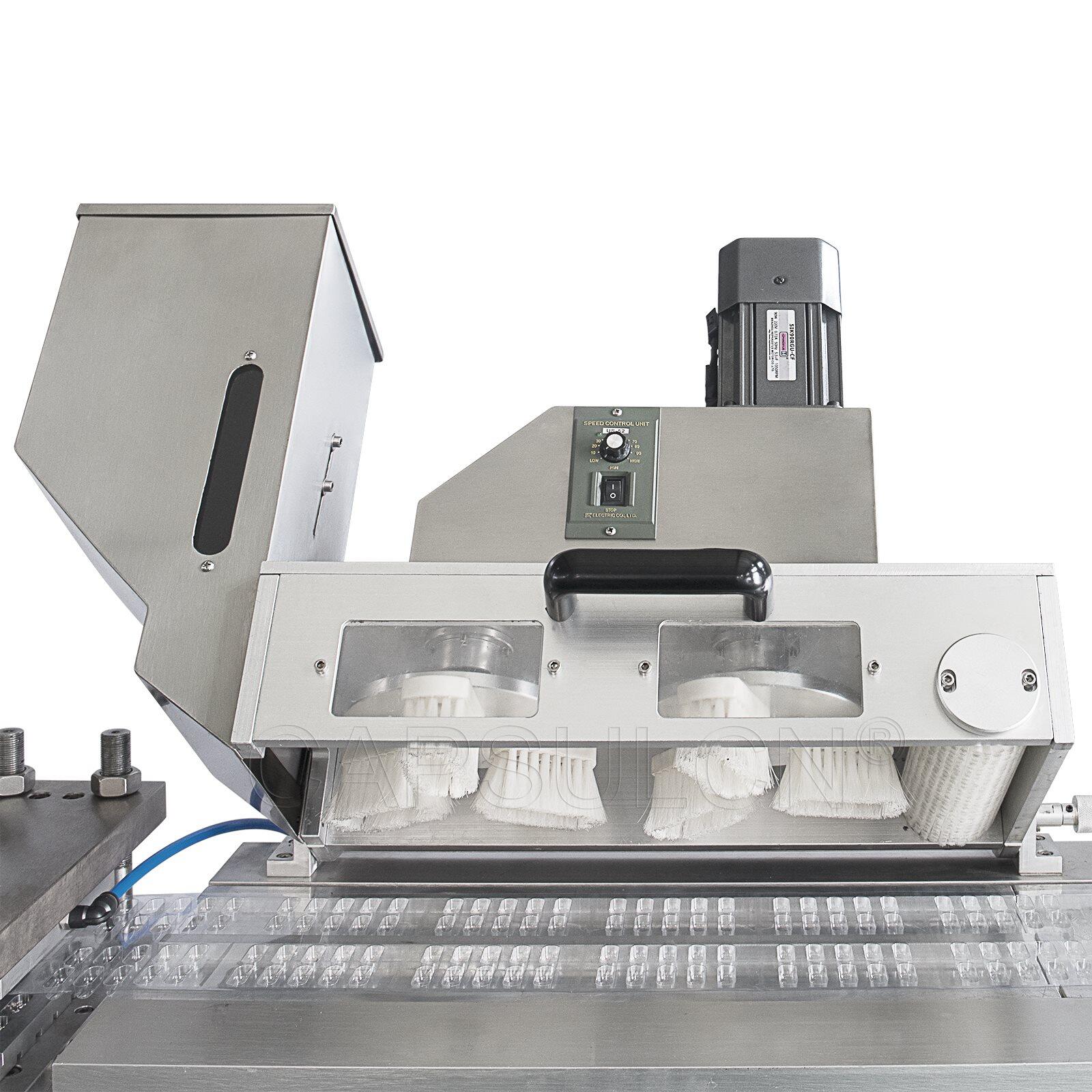

After the PVC is formed, it is transported to the filling station by a driving device. The filling is controlled by the machine with a constant speed, and accuracy. For pill generally spreading type is adopted. The feeding speed shall be constant to the forming speed. the accuracy of different machines was quite different. After filling the product, check manually or by sensor, and adjust manually if necessary. However, it is more common to use a rotating soft brush to sweep while the PVC is stepping, - extra pills will be pushed to the bottom, and then the soft brush pushes the pills to fill the empty blisteres.

Heat-sealing

Immediately after filling the product, it needs to be sealed by the substrate. In the case of packaging Pill, aluminum foil is generally used as the material, and there are generally two kinds of heat-sealing:

Rolling type: PVC tape and aluminum foil are heat-sealed by the mutually parallel heat-sealing roller and the anilox roller under the action of a certain temperature and pressure. The time is extremely short when the material passes through two rolls, thus, to obtain a qualified heat-sealing effect, the speed of the rolls shall be very slow and need to be fully preheated before.

Plate pressing type: use the heated sealing plate and the lower template to press the blister and the substrate for sealing. With this method, the blister packaging is flatter and the pressure required for sealing is bigger.

There are generally bit a bit shape or a mesh texture on the surface of the heat-sealing plate (roller). This is the texture we will see on the finished aluminum foil. It is used to stretch the material sealed, eliminate the wrinkles, improve the sealing effect, make aesthetic appearance and increases friction.

Trimming, printing, rejecting scrap

Gone through above steps, the product packaging has been roughly completed, and then trimming, printing, and scrapping of the waste work are needed. At this time, the blister is still integrated, and it is transported to the trimming station for trimming, and the corners are usually shaped to be round. In some cases, a fragile intermittent short mark is punched on a blister for manual splitting.

After that, necessary information such as the date of manufacture, lot number, etc. is printed on the blister through the printer, and finally the unqualified blister is removed. In addition, some machines can also directly pack the blister.

Through the above steps, the blister package can be completed.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche