Video

Introduction

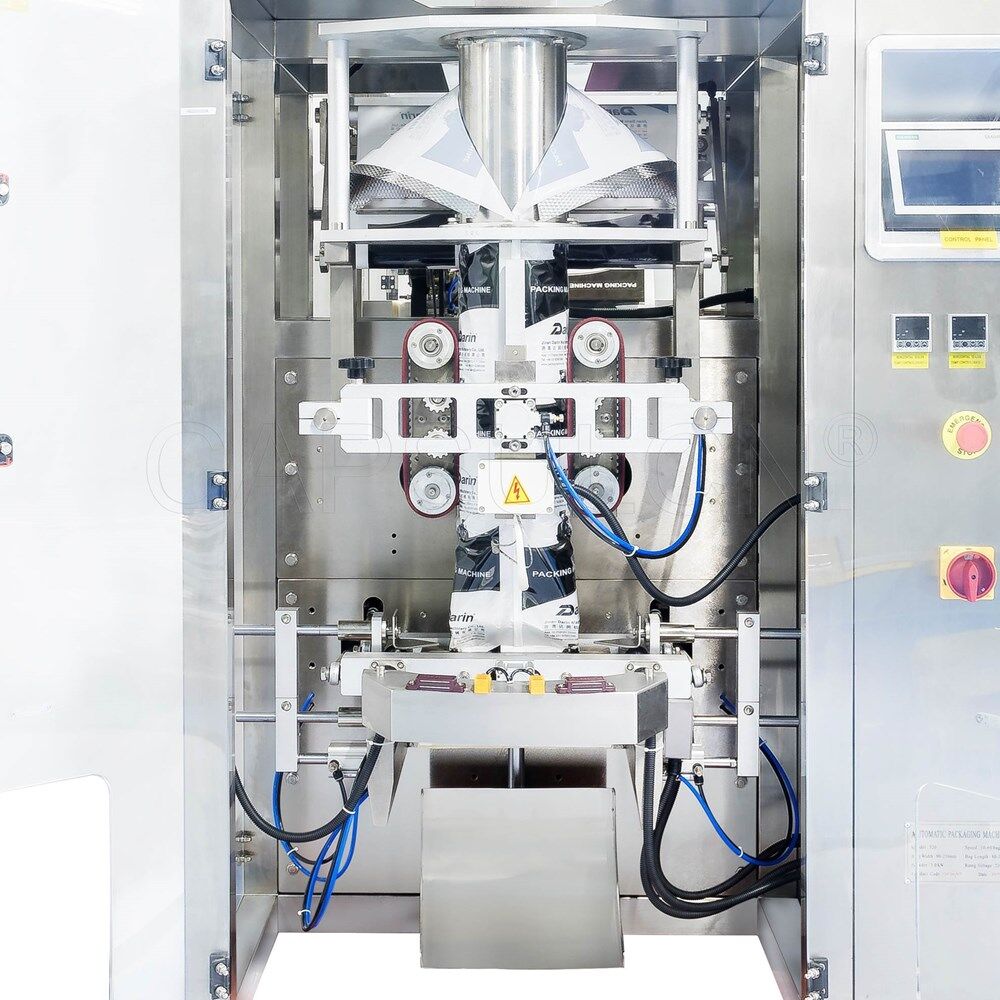

Vertical bagging systems essentially refer to a specific kind of vertical packaging machine also known as a vertical form fill seal machine. This particular piece of bagging machinery and equipment is a type of automatic packaging unit that is commonly used in the food packaging industry.

Specifications

| Model | BVL-520 |

|---|---|

| Packing film | OPP/CPP、CPP/PE ,etc composite materials can be hot sealing, require to use in roll. external diameter≤400 mm,inner shaft diameter 75mm;The surface of packing film must smoothly, Not have wavy on the edges, within 10mm of edge can not print words and figure, the mark and packaging film base color contrast to sharp. |

| Making bag size | (W) 90-250mm; (L) 80-360mm,the length can up to 450mm after pushing the belt second time. |

| Packing speed | 5-70bags/min |

| Thickness of packing film | 0.05-0.10mm |

| Powder | 3.2 KW |

| Air consumption | 0.7Mpa 300L/min |

| Dimension | W118*L150*H153 (cm) |

| Weight | 650kg |

Feature

- The structure is compact, electrical components, pneumatic components used in the factory of products, to ensure long-term stable working machine

- The PLC program control, full Chinese / English touch screen operating system, clearly show the working state and operating instructions

- Adopts high precision servo film transporting system, transport membrane smooth, combined with photoelectric automatic tracking location system, high positioning precision.

- The intelligent digital temperature control system, temperature control and stability, sealing device with tooth, ensure firm sealing.

How it work?

- Film Transport & Unwind: the film is usually pulled off the roll by film transport belts

- Film Tension:During unwinding, the film is unwound from the roll and passes over a dancer arm which is a weighted pivot arm located at the rear of the VFFS packaging machine. The arm incorporates a series of rollers. As the film transports, the arm moves up and down to keep the film under tension. This ensures that the film will not wander from side to side as it is moving.

- Printing:Printers may be thermal or ink-jet type. The printer places desired dates/codes on the film, or may be used to place registration marks, graphics, or logos on the film.

- Film Tracking and Positioning:Once the film has passed under the printer, it travels past the registration photo-eye. The registration photo eye detects the registration mark on printed film and in turn, controls the pull-down belts in contact with the film at the forming tube.

- Bag Forming:From here, the film enters a forming tube assembly.

- Bag Filling and Sealing:formed bag can receive its vertical seal. The vertical seal bar, which is hot, moves forward and makes contact with the vertical overlap on the film, bonding the layers of film together.

Information we need before order

- What product will you pack?

- How many gram and volume in each bag?

- What bag shape you want to get?

- What is bag width and bag length?

- What bag material do you want to use?

review(s)

GOOD

The whole machine has advanced design, reasonable structure, automatic correction, automatic alarm protection function, and minimize loss.

From: Davis | Date: 3/1/2021 4:23 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Small Volume CH Type Powder Mixer Powder Blender CH10-CH50

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche