What Are Capping Machines And How Do They Work?

In our daily lives, fastening a bottle cap sounds like an easy task. However, for the pharmaceutical industry, capping is a critical job. Because of its nature, medicine has strict requirements on container sealing performance. So, purely manual capping may be difficult to fulfill that. At this point, we need a professional capping machine. It can seal the container tightly, so that the product will never be contaminated or leaked.

Well, do you know how the capping machine works? Without further ado, let's reveal the secret about the working principle of the capping machines!

What Is A Bottle Capping Machine?

Simply put, a bottle capping machine is used to put and tighten caps into bottles. By design, it is a simple and safe device. However, it offers advantages in terms of accuracy and speed over purely manual capping. So, it has become an integral tool for the pharmaceutical and food industries.

How Do Different Types Of Capping Machines Work?

Whether you're an expert or just starting out in the packaging industry, understanding the working principle of capping machines can be beneficial. With this knowledge, you can increase productivity on your own and even cut a lot of labor costs.

If you've done your research, you've probably found that there are many different types of capping machines on the market. Just like liquid filling machines, capping machines come in manual, semi-automatic and fully automatic versions. Here's a closer look at how each type works!

How Does A Manual Capping Machine Work?

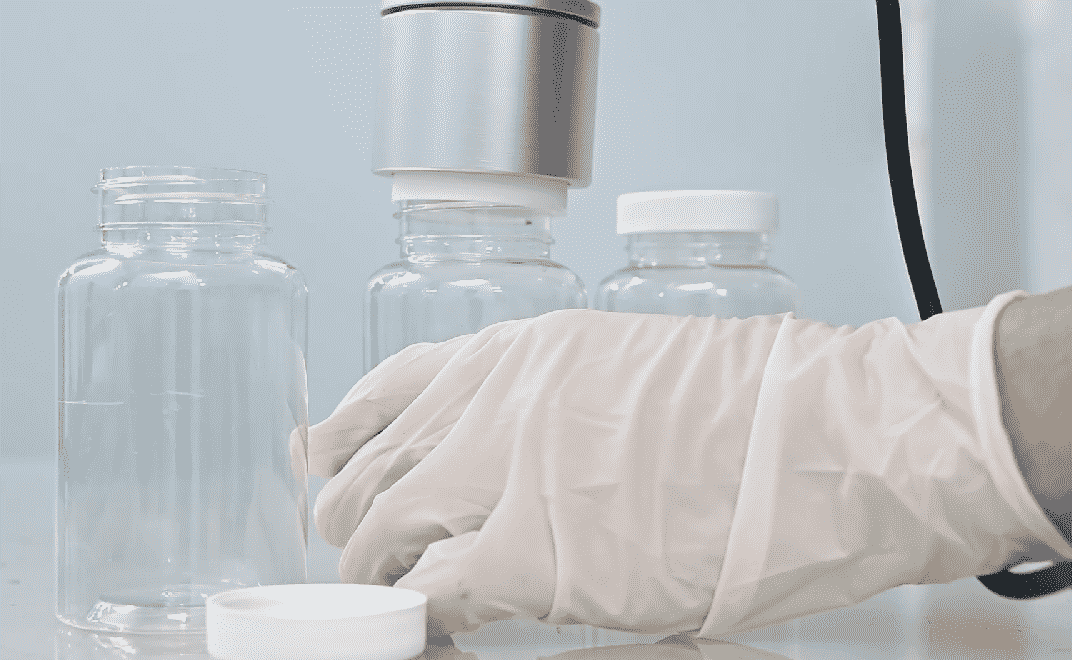

Manual capping machines are portable devices used to manually cap bottles. They are often applied in small scale production.

Below is the working principle of a handheld capping machine:

Step1: Placing the bottle

For the very first step, place the bottle on a level surface. Please make sure the bottle is placed vertically and steadily, which is to prevent it from tipping over during the capping process.

Step2: Putting the cap on the bottle

In this step, you may fix the bottle cap to the bottle's mouth, and you should note that the cap must be aligned with the bottle's mouth.

Step3: Clamping the cap

The capper is now out of the box. Align the gripper of your handheld capper with the bottle cap. It will then apply pressure to grip the cap tightly. This step is to stop the cap from falling off during the screwing process.

Step4: Tightening the cap

Press down firmly on the handle of the manual capper, and the chuck starts spinning to tighten the cap. You can then release the handle and let the chuck release the cap. That's how a complete capping process comes to an end.

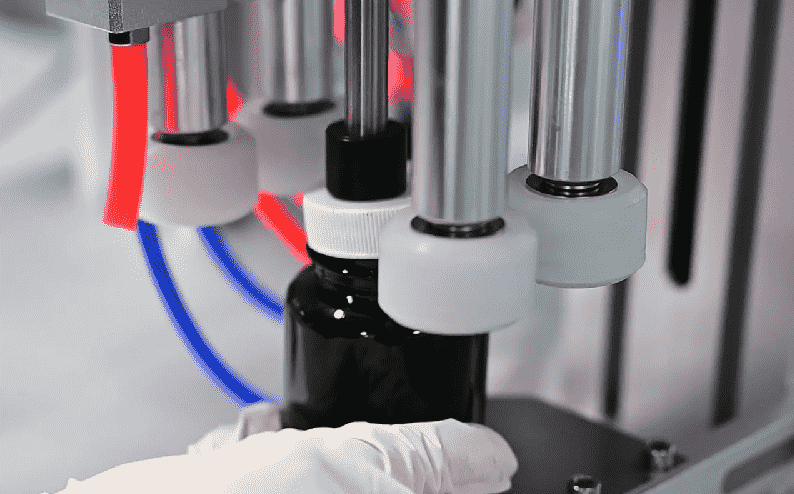

How Does A Semi-Automatic Capping Machine Work?

The workflow of the semi-automatic capping machine consists of manual operation and machine automation. This device is ideal for medium-scale pharmaceutical packaging. Let's find out how it works!

Step1: Applying the bottle cap

First of all, you need to manually place the cap on top of the bottle, and then move the bottle to the machine base. Remember to keep the bottle stable here. Now that the bottle is perfectly in place, it's ready for capping.

Step2: Turning the switch on

For the second step, you only need to press the foot pedal switch gently. It controls the cylinder, which in turn drives the motor to move up and down. Once the switch is on, the cylinder will lead the chuck down to the cap you want to tighten.

Step3: Tightening the cap

When the chuck touches the cap, a force pushes the chuck to connect with the motor, which will start working. This will tighten the cap in a few seconds and then stop automatically. In this way, the tightening of a cap is roughly done.

Step4: Taking away the bottle

At last, you can turn off the foot pedal switch. The chuck will release the bottle cap and go back to where it started. Now you are free to take the capped bottle away.

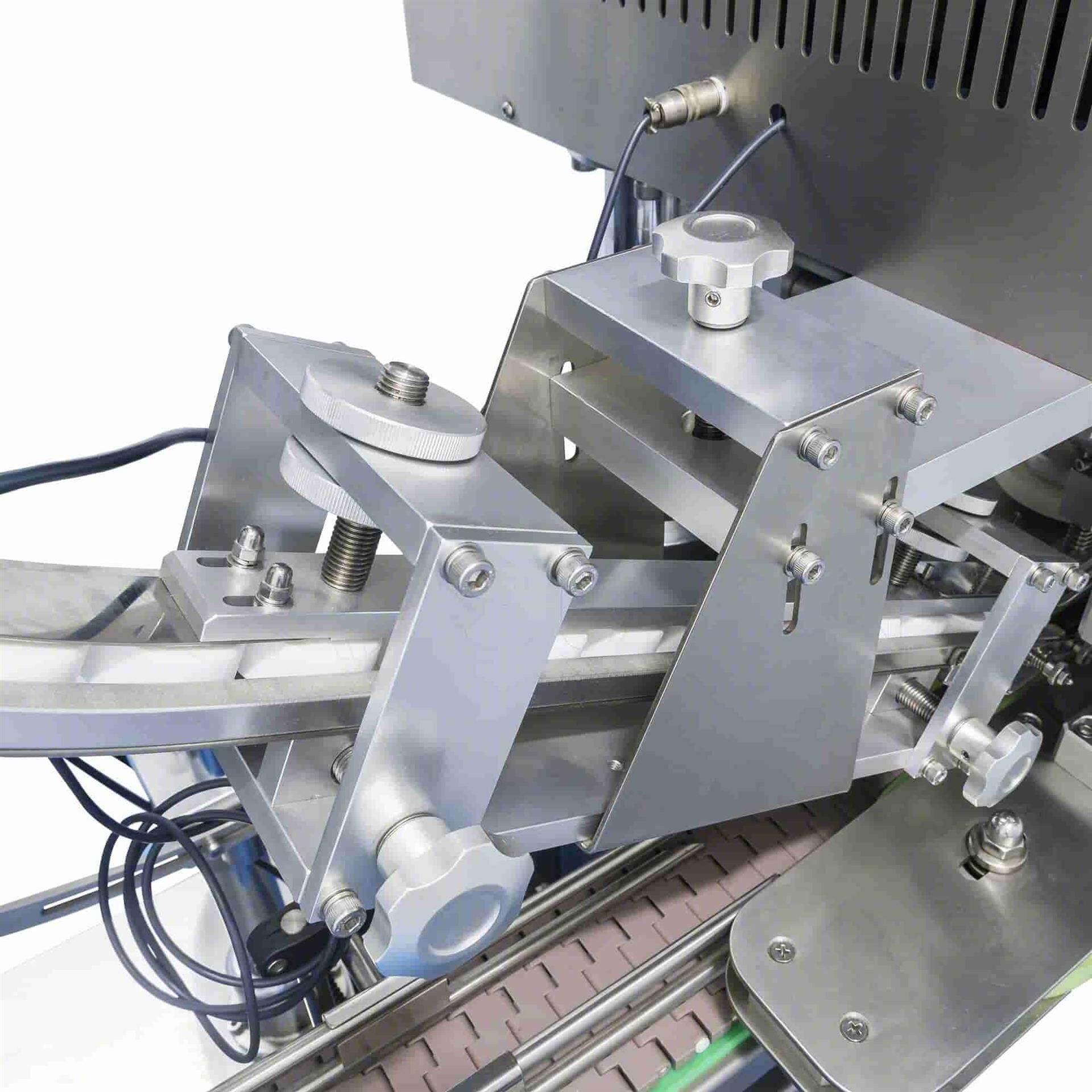

How Does An Automatic Screw Capping Machine Work?

The automatic screw capping machine is so smart that it can complete the whole capping process without manual intervention. So, it is a good option for pharmaceutical companies who demand high productivity and efficiency. Its ability to efficiently and accurately cap bottles depends on the synergy of the capping machine's key components.

Have you ever noticed that automatic screw cappers usually come with two capping methods? The chuck capping and the spindle capping. In this section, we'll use the spindle capper as an example to break down its working principle.

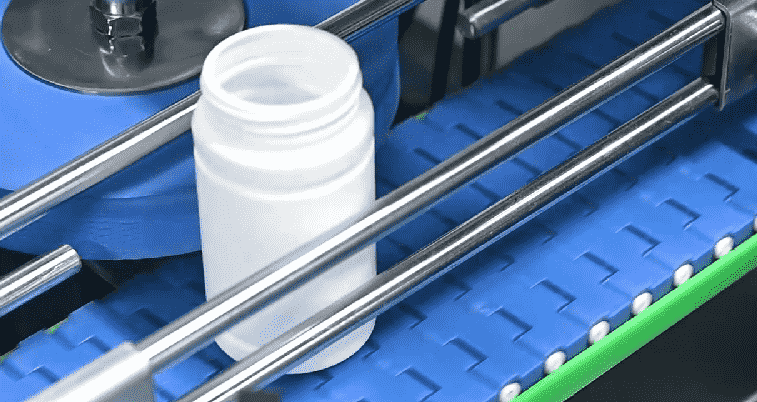

Step1: Transporting bottles

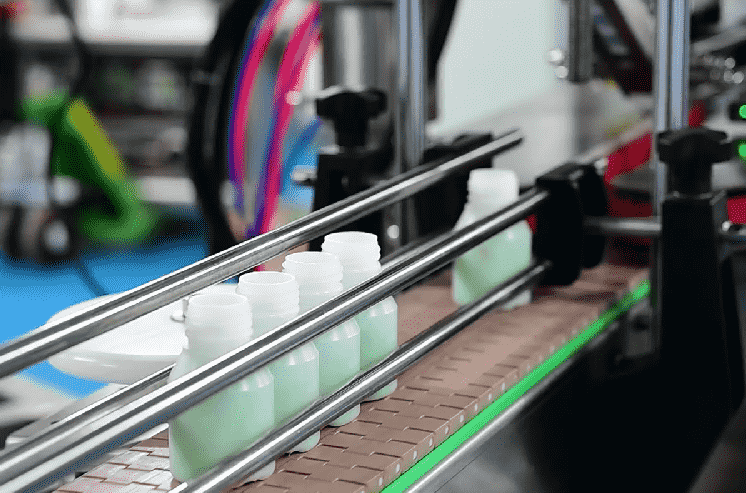

The very first step is placing the uncapped bottles on a conveyor belt, which will then automatically transport these bottles to the capping station.

Step2: Feeding caps

At this stage, pour all the caps into a hopper. The caps are then delivered to the cap dropping part, ready to start the next process. The automatic screw capper typically has a cap sorting function. So, if a cap is upside down, it will be sent back to the hopper.

Step3: Keeping the bottle stable

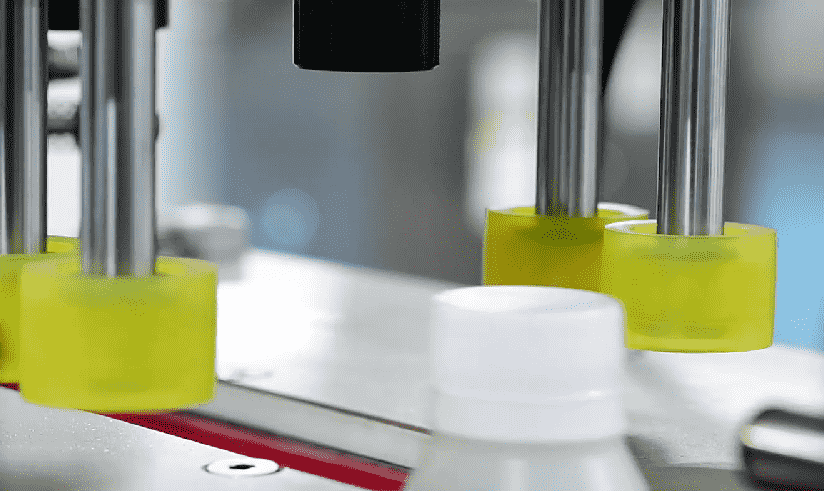

After the caps have dropped onto the bottles, they will soon leave for the screwing station. Normally, automatic screw capping machines are equipped with a holding system to protect the bottle and the cap. Also, there are two important components in this system: one is the gripping belt, which keeps the bottle from tipping over. The other is the cap stabilizer, which prevents the cap from falling before entering the screwing station.

Step4: Screwing the caps

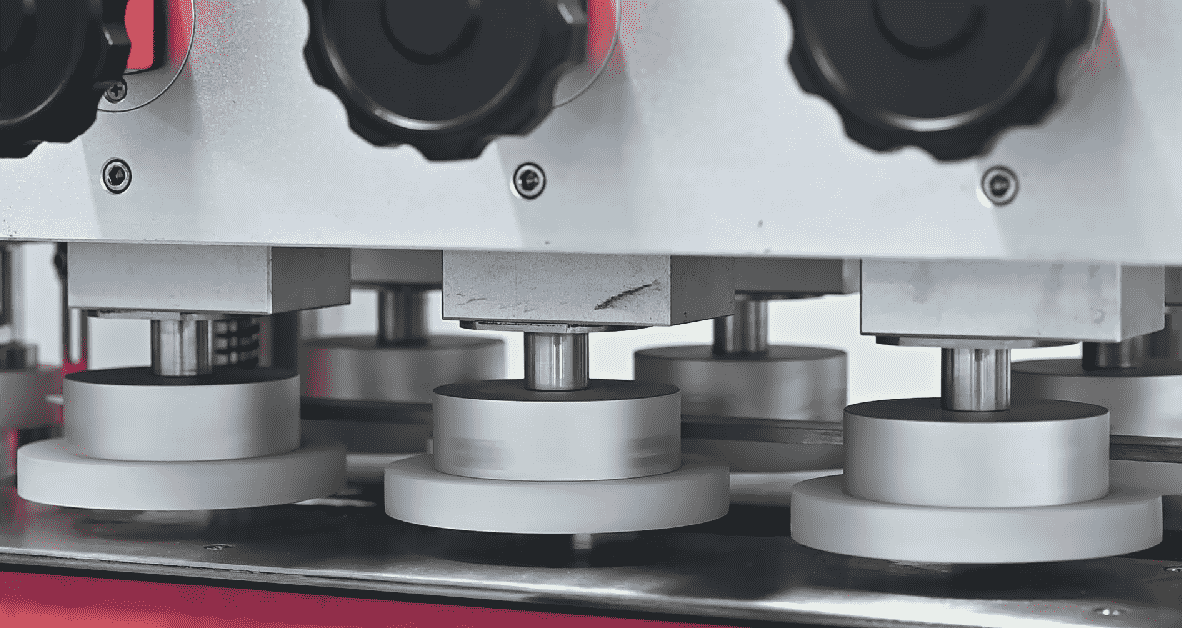

When a bottle enters the screwing station, the auto capping machine typically has six spindle wheels to apply torque to the cap. Then they slowly tighten the caps onto each bottle. For your information, you can adjust the spacing between these wheels according to the cap size and bottle height.

Step5: Releasing the caps

Like the two types of cappers mentioned earlier, the final step in an auto screw capper is also releasing the cap and sending the bottle away. Once the bottle is capped, it leaves the capping station and travels on a conveyor belt to another packaging station.

After reading through this guide, you probably have mastered how each type of capping machine works. In the long run, this can help you improve your efficiency and product quality.

Ipharmachine is one of the top capping machine manufacturers who can also offer you expert pharmaceutical packaging solutions. If you have any questions about capping machines, please feel free to contact ipharmachine.

IPharMachine Systems For All Your Bottle Capping Needs

iPharMachine is a global leader in the manufacture of capping machines. With 30 years of experience in the packaging industry, we can offer you a wide range of bottle capping systems. In addition to supplying single packaging machines, we can customize a packaging solution for you. Whether you need a manual capper for small-scale operations or a fully automatic capping system for mass production, iPharMachine has you covered.

Looking for a reliable bottle capping system? Contact us today for more information and find the perfect capping solution for your company.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche