11 Equipment in Capsule Filling Line: From Raw to Final

A capsule filling line is also known as a capsule production line. It can automate or semi-automate the process from powder processing to bottle packaging. There is a series of machines involved to complete the whole process. In this post, I want to introduce you to the 11 most important machines in the filling line. Then you may have a basic understanding of how it works.

Powder Grinder Machine

The fineness of the powder affects the accuracy of capsule filling. The powder used is not in such a fine state at the beginning. The raw material needs to be ground by a grinder machine at first.

The machine can make big materials like particles into very small pieces. Also, you can change the settings to make the powder finer or coarser, just like grinding coffee beans in a coffee machine.

The powder grinder machine can process a wide range of materials to meet your needs. It also comes in all sorts of sizes. Whether you want to use them in a small workshop or big factories for high volume, you can find the type you want.

Powder Sifter

A powder sifter is used to separate powders from other materials like pellets or tablets. It also lets you choose different sizes of powder. Then, you can get it in the size you need.

The powder sifter works mainly with a vibration motor and has many layers of screens. You can choose the size and number of the screens based on your needs. This tool plays a big role in making sure the materials are all the same size. This way, the amount filled in each capsule can be more accurate. This machine can be used in different industries, like making medicine or food, cosmetics, etc.

Automatic Capsule Filling Machine

The automatic capsule filling machine is the main device in the capsule filling line. It's made to fill capsules with the same amount of stuff automatically. It can be filled with all kinds of powders, granules, and pellets. Moreover, it can work with different sizes of capsules and can be adjusted to fill different amounts of powder.

This machine can significantly increase the speed and accuracy of capsule production. It is widely used in pharmaceutical manufacturing, as well as in industries that produce dietary supplements, herbal supplements, etc.

Semi-automatic Capsule Filling Machine

Compared to automatic one, the semi-automatic capsule filling machine needs some things to be done by hand. For example, you need to pour empty capsules into the capsule hopper by yourself, or separate the capsule bodies and caps.

Other functions are pretty much the same as the fully automatic capsule filler. It can also fill capsules of different sizes, and you can adjust how many capsules you want to fill.

This machine suits small to mid-size businesses needing automation, not high-volume production.

The four machines above are used for handling the raw materials and filling the capsules in the filling line. The next machines we'll talk about are mainly for processing and packaging filled capsules.

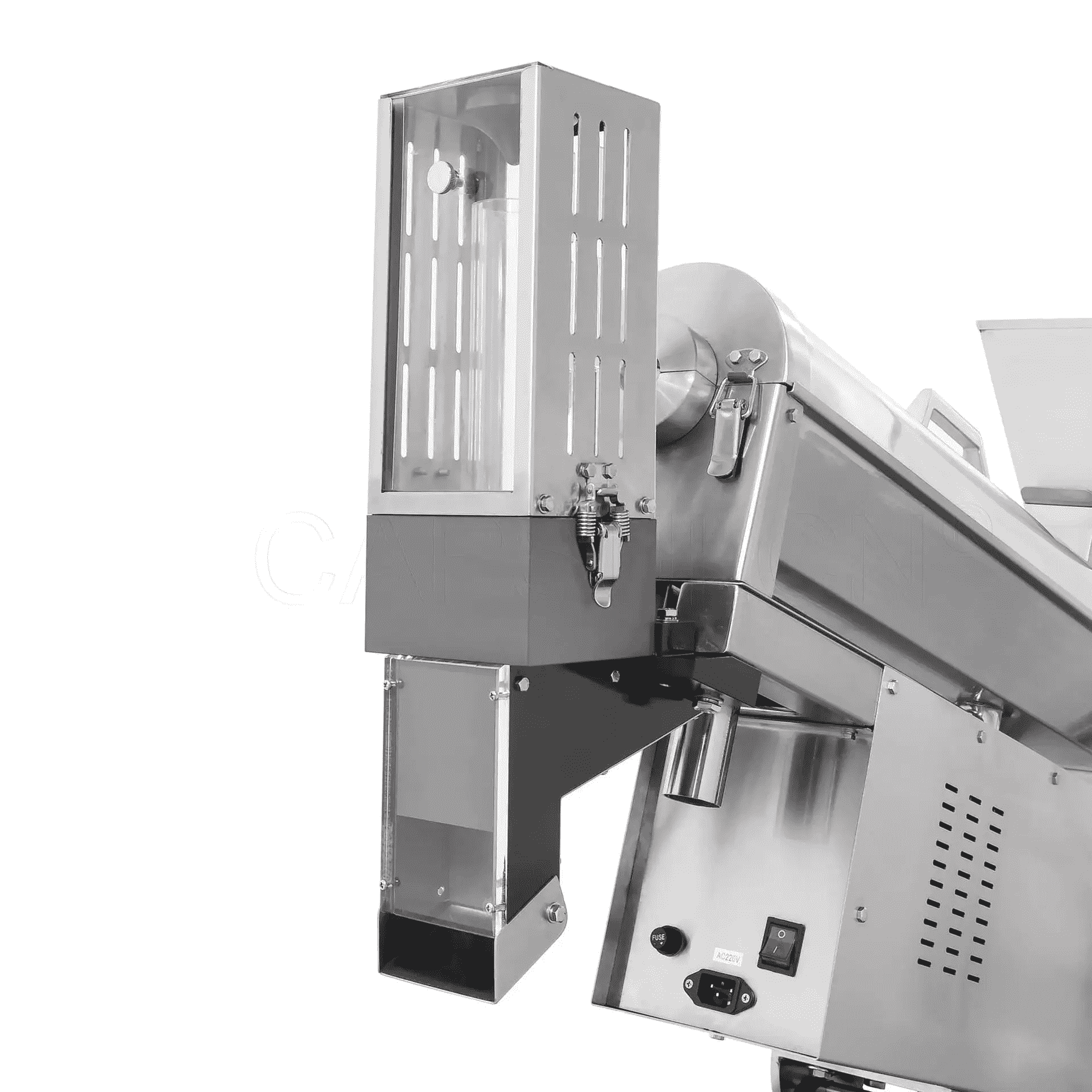

Capsule Polishing Machine

Because finished capsules might have dust or dirt on them, they need to be cleaned by a polishing machine. The capsule polishing machine can get rid of dust and small pieces on the capsule's surface, making them clean and shiny. It ensures the capsules are clean enough to meet health standards and make them look more appealing.

In addition, the capsule polishing machine can also get rid of static electricity for capsules.

Capsule Sorter

This machine is used to separate capsules that meet the standards from those faulty capsules. Common problems include empty capsules, separated capsule bodies and caps, and broken or deformed capsules. This ensures that only high-quality products reach the consumer.

You can set up a separate capsule sorter on the production line. Or you can choose a capsule polishing machine with sorting capabilities. It is able to directly solve polishing and sorting in one go.

Metal Detector Machine

This metal detector is part of capsule quality control. It can check if there are any metal things, like iron or steel. It can also find tiny metal pieces or wires embedded in the products. If there is something metal in the capsule, the machine usually makes a noise and light to warn us. And it will automatically get rid of the bad product through baffles while it's falling.

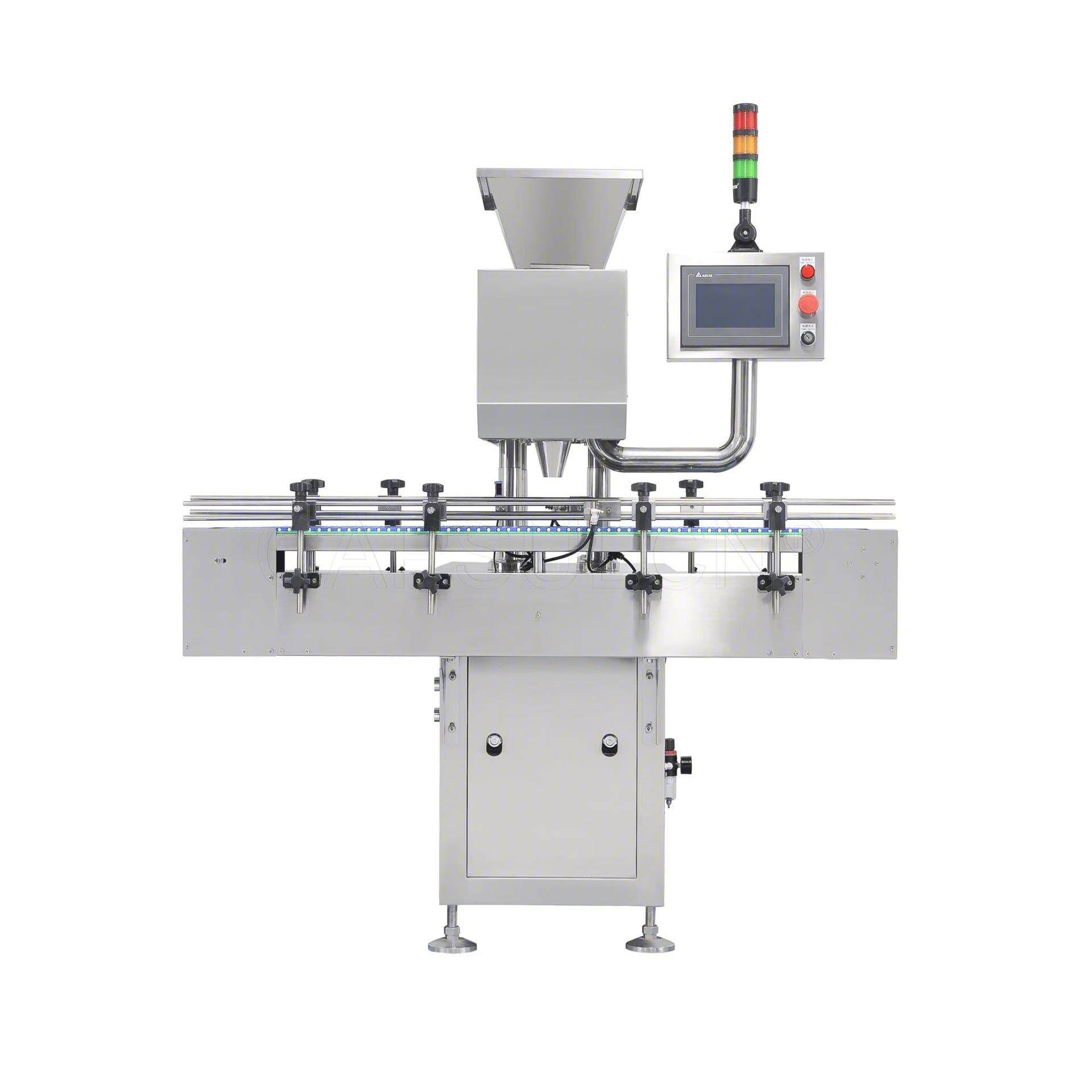

Capsule Counting Machine

In the medicine-making business, counting capsules correctly is important to make sure the right amount and keep patients safe. So, we need a machine that counts capsules in the capsule filling line. It can count different types of capsules, whether they are soft or hard.

Most of capsule counting machines use visual sensing technology. The sensors can detect and count each capsule as it falls into a container. When the number of capsules reaches the set amount, the bottle they are in is moved to the next step. This machine works fast. Also, it is easy to use and take care of.

Bottle Capping Machine

This machine is used for tightening the caps on the bottles. It makes sure the caps are put on safely and consistently, ensuring product quality. For capsule bottling, common ways are screw capping and press capping.

Bottle capping machines can work with various types and sizes of bottle caps, such as round, rectangular, irregular shapes, etc. You can also customize the cap-twisting part to fit the size of the cap you need.

Bottle Induction Sealer

This machine is used to make sure the medicine is sealed well. Usually, we use aluminum foil to seal the bottle, and that's when we need induction bottle sealers. It uses a thing called electromagnetic induction to heat up and melt the aluminum foil. Then it sticks to the bottle opening. This helps keep the medicine dry, stops it from leaking and mold, and makes it last longer.

Besides the medicine-making business, the bottle induction sealer is also used a lot in the food business and the makeup business.

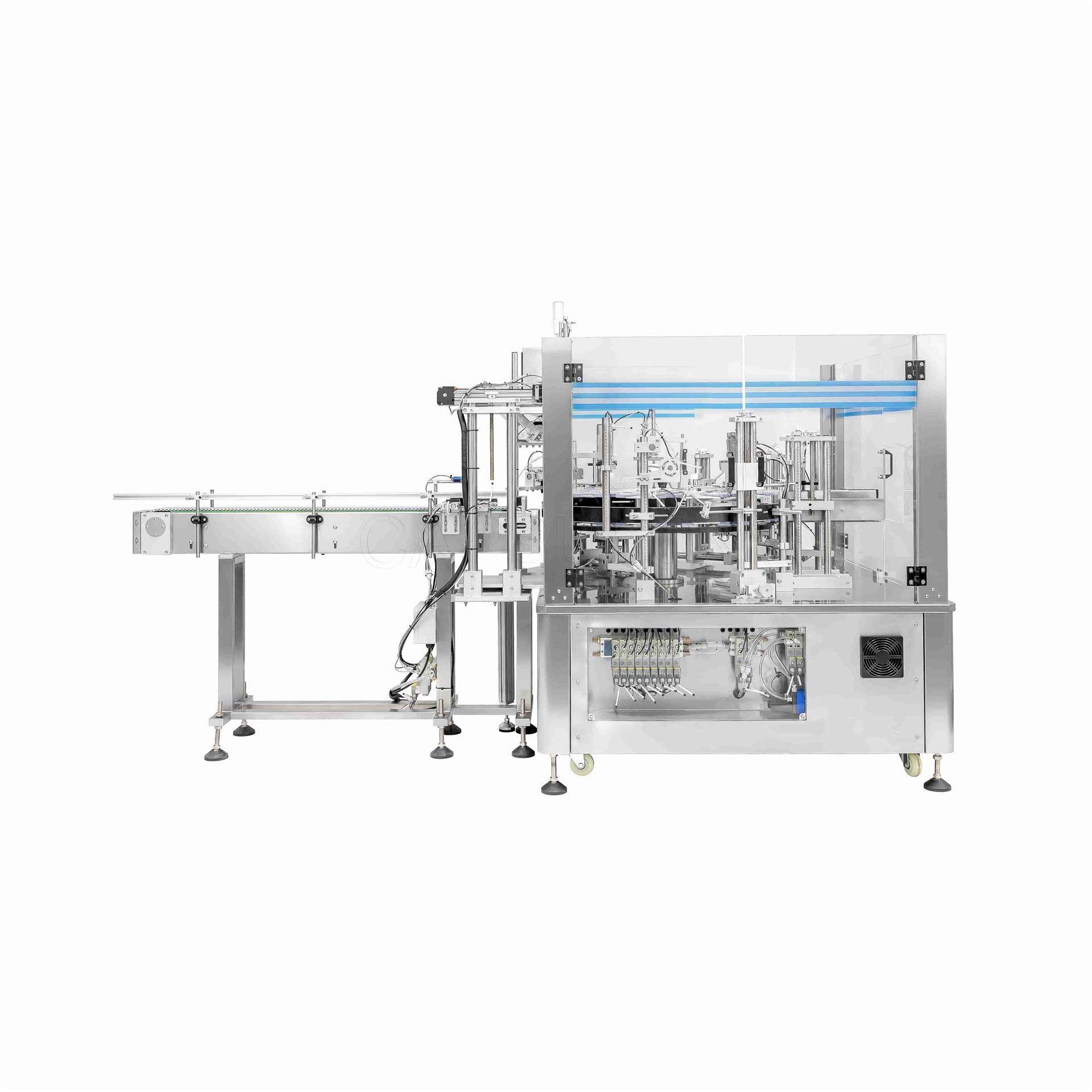

Carton Packaging Machine

This machine is for packing medicine bottles. The whole process includes automatically putting the finished product into a paper box and sealing it. This makes sure every box is packed and sealed in the same way, giving a consistent look and quality.

Most of carton packaging machines can handle paper boxes of all shapes and sizes.

The End

Besides the machines mentioned above, some capsule filling lines might also include machines like a powder granulator and a dust extractor. You can change the arrangement of machines on the production line based on your production needs.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche