A Look at the Critical Stations of an Automatic Encapsulation Machine

Automatic capsule filling machines are at the heart of the pharmaceutical industry. These machines are widely used to produce high-quality capsules for countless medications. Complex and sophisticated, each piece of capsule filling equipment comes with many different parts. These capsule filling machine parts work together to create accurate and consistent doses.

Every manufacturer aims to achieve fast, efficient capsule filling. Yet, did you know what parts of the machine are critical? The entire capsule filling process is done by multiple critical stations. Each station performs its own functions to deliver a homogeneous final product.

In this blog post, we'll explore the important stations of an automatic capsule filling machine and their functions. So, whether you're new to the world of pharmaceutical engineering or simply want to learn more about capsule filling, keep reading.

6 Stations of an Automatic Capsule Filling Machine

If you want to figure out the entire capsule filling process, let's break it down into several machine functions. These functions are performed at separate stations. They include orientation & separation, dosing & filling, faulty capsule ejection, closing, discharge/ejection, and cleaning stations.

1. Capsule Orientation & Separation Station

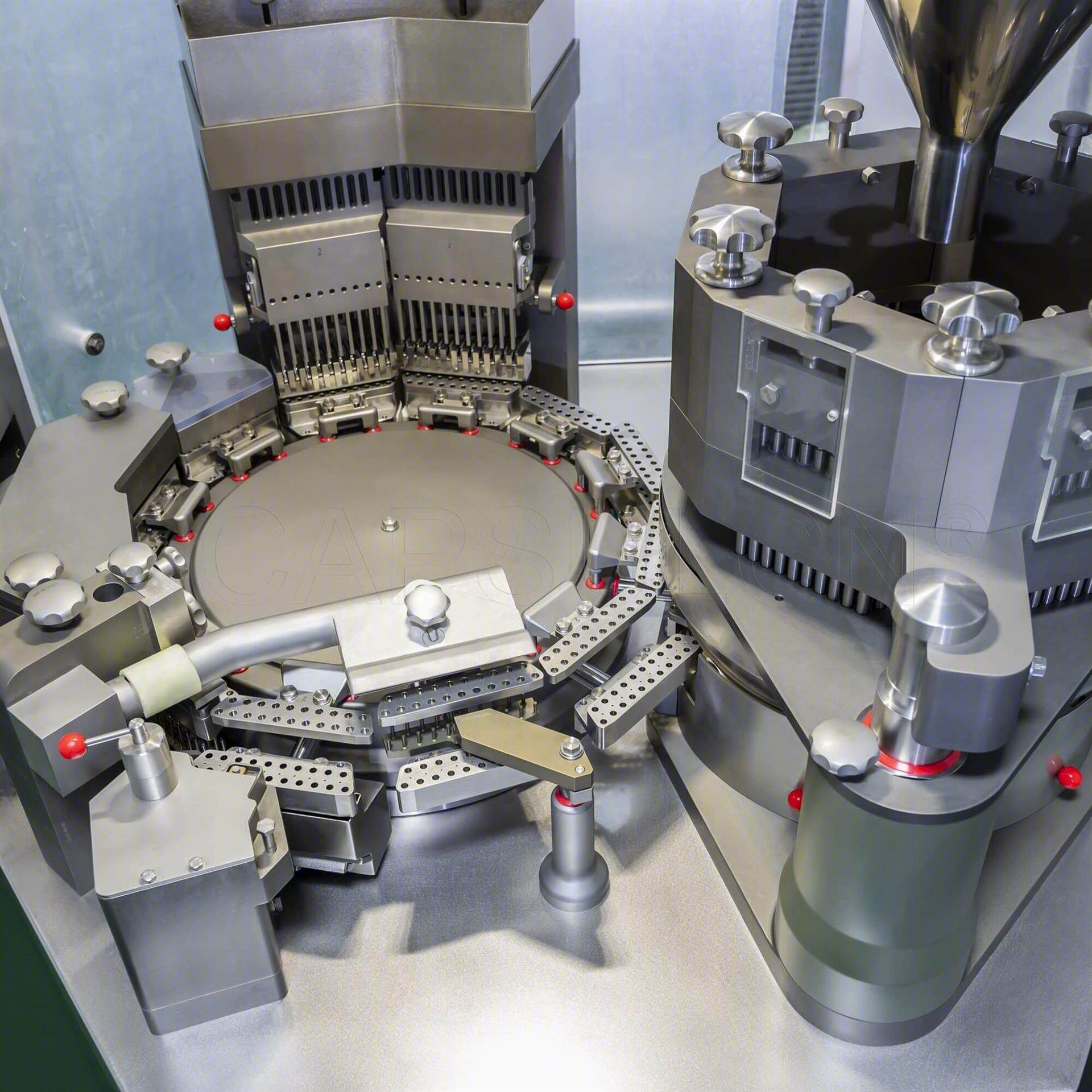

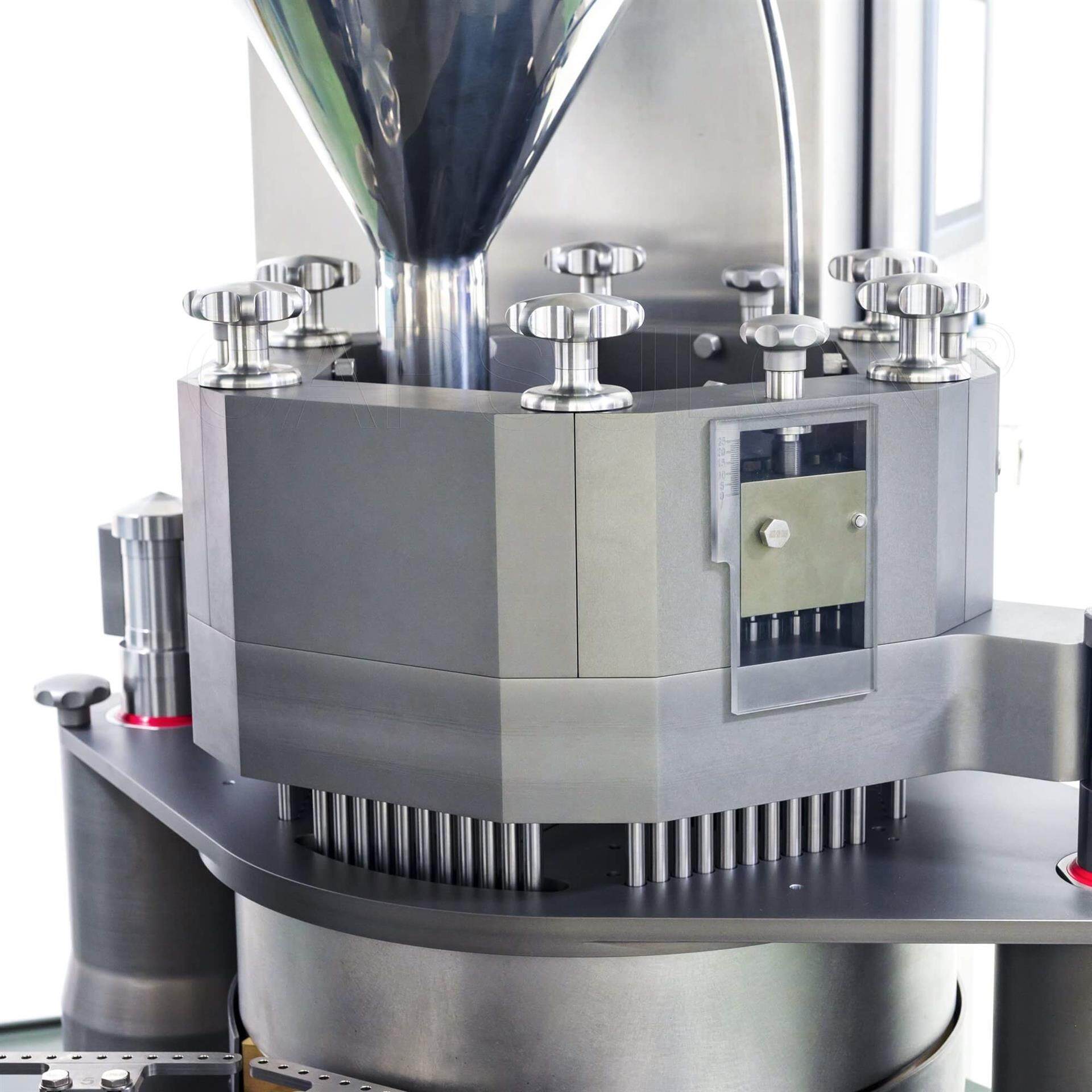

As the name implies, this station is designed to complete two tasks. It consists of multiple major parts, such as the capsule feeding unit, capsule tooling, and vacuum system.

After empty capsules are loaded into the machine, they move downward along the magazine channels of the capsule feeding unit. These capsules might not be lined up in the same direction during this stage. So, the orientation needs to be done first. The empty capsules gently deposit into the sorting block with the caps at the top and the bodies at the bottom. And then, the vertical fingers push them into the segment bores.

The tooling separates into two halves as soon as the capsules sit in the segment bores. At this moment, the vacuum system pulls the bodies loose to open the capsules. When both caps and the bodies are securely positioned in their respective upper and lower segments, the separation process is successfully completed. After that, the tooling moves to the filling station.

The orientation and separation station is capable of handling a wide range of capsule shapes and sizes. This can be achieved through tooling changeover and adjustable settings. The tooling can be customized to meet the specific needs of each production run.

This station plays a critical role in ensuring the accuracy and efficiency of the automatic capsule filling machine at the very beginning.

2. Dosing & Filling Station

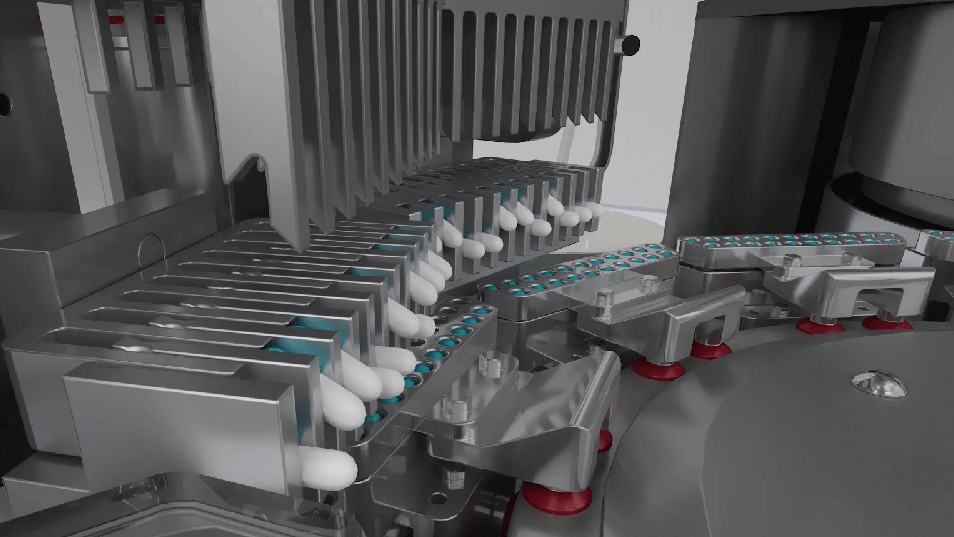

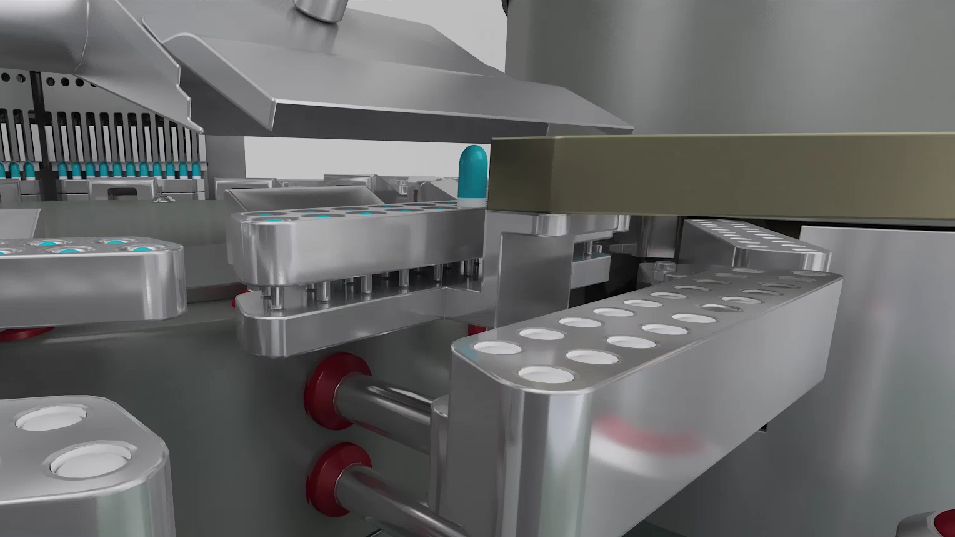

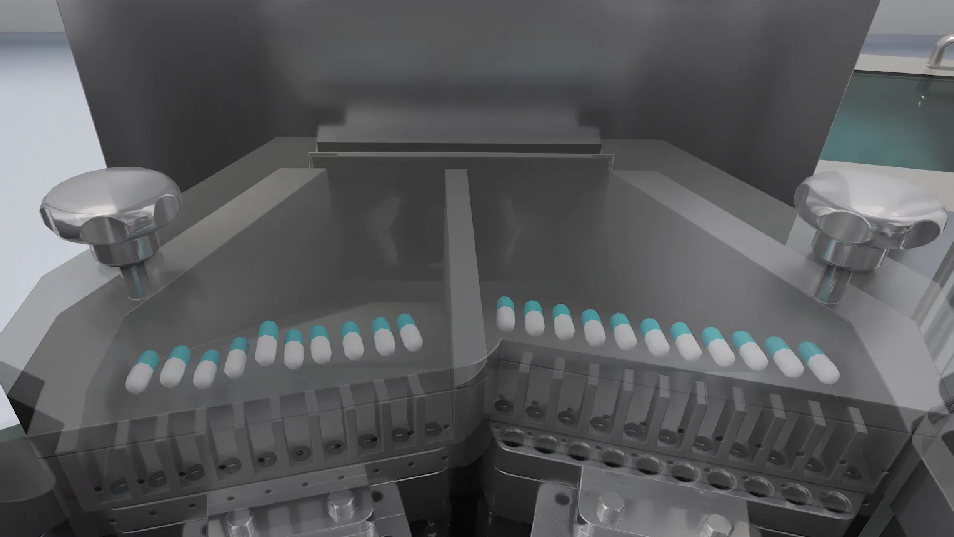

This station differs depending on the filling system. As shown in the above picture, the dosing disc system is widely used for most automatic capsule filling equipment.

This system uses tamping pins for dosing and filling powders, also called a tamp filling system. It consists of a powder bowl, a dosing disc with six groups of holes, a tamping ring, and multiple tamping pins. The system has five stations for tamping and one station for transferring.

After the powder is fed into the station, these tamping pins move up and down through a powder bed. The powder is tamped five times to form a uniform plug inside the dosing disc hole. When the system rotates to the transfer station, the pins force the powder plugs out of the holes and push them into the capsule bodies.

Aside from the dosing disc system, there are other options like dosator filling, vacuum filling, and more. It's worth mentioning that the dosator system is a solid choice for micro-dosing operations. It's capable of filling capsules used in dry powder inhalers.

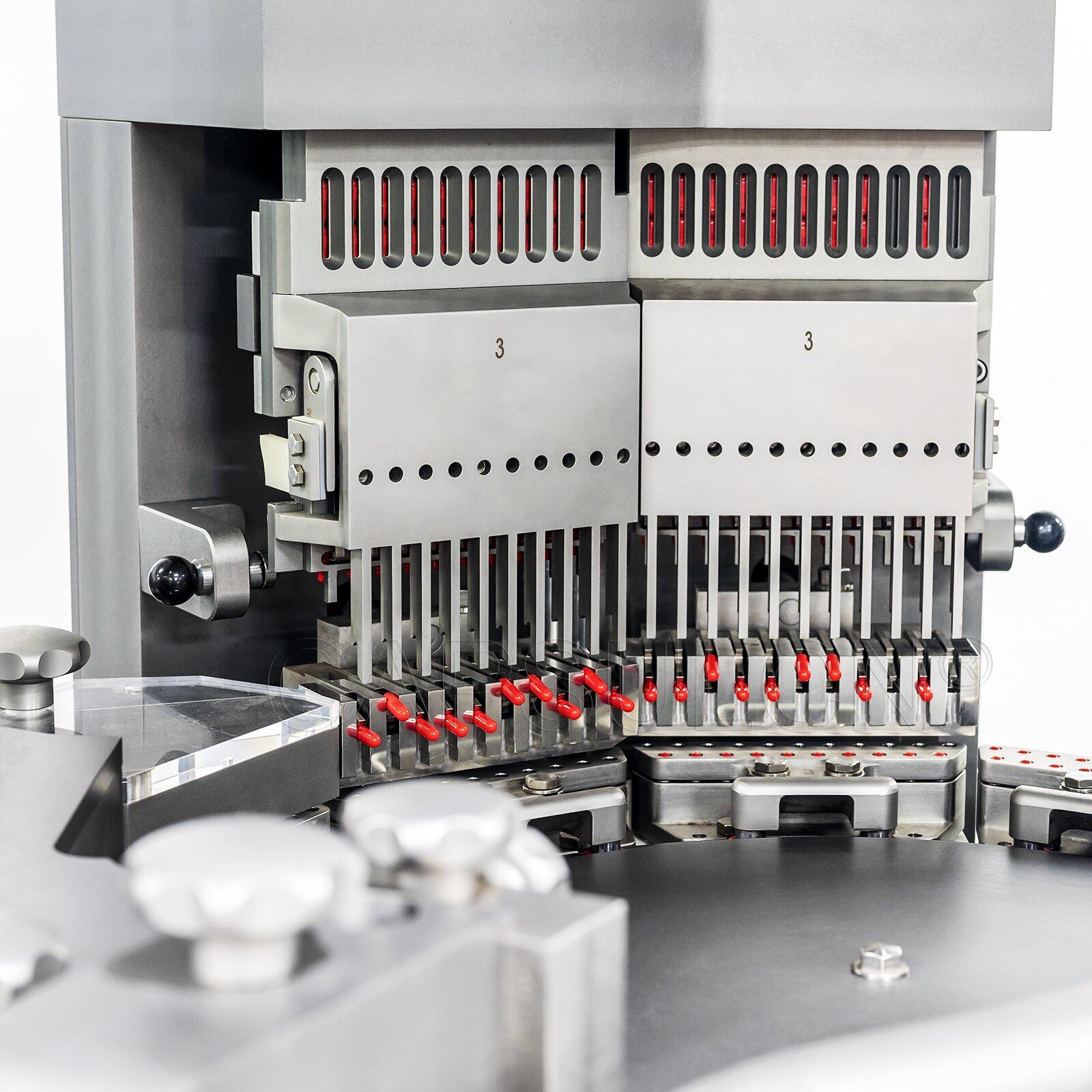

3. Faulty Capsule Ejection Station

Most medium or large-sized automatic capsule filling machines are built with two ejection stations. The first ejection station is generally located following the dosing and filling station.

The faulty capsule ejection station works by using sensors to detect any improperly inserted capsule cap or non-separated capsule. Once any fault is detected, the cap or capsule is automatically ejected out of the segment bore. And then, the faulty capsule is rejected from the production run using an air blast.

The rejected capsules are usually collected in a separate container for disposal or further inspection. This ensures that only high-quality capsules are used for the final product. It is important for maintaining product safety and efficacy.

It's worth noting that the specific design and functionality of a faulty capsule ejection station may vary depending on the model of the automatic capsule filling machine.

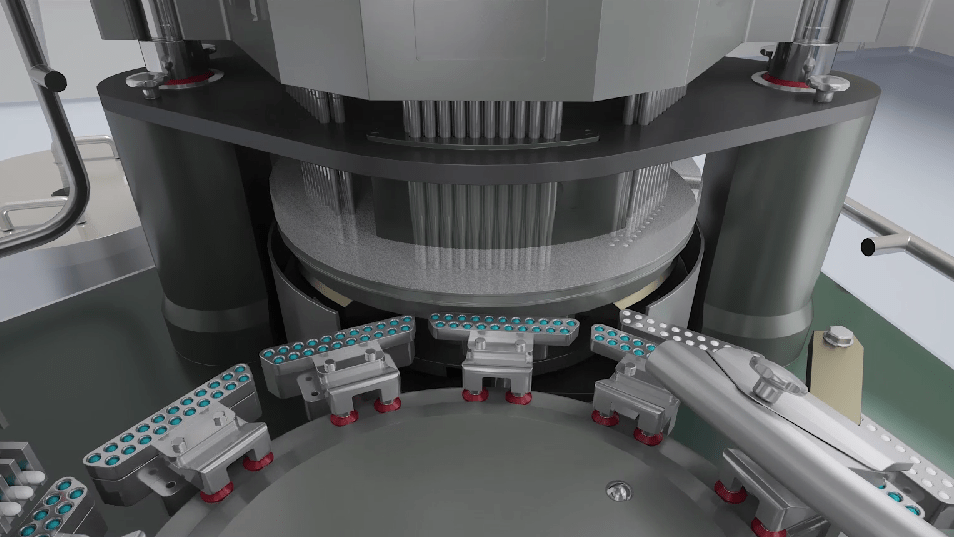

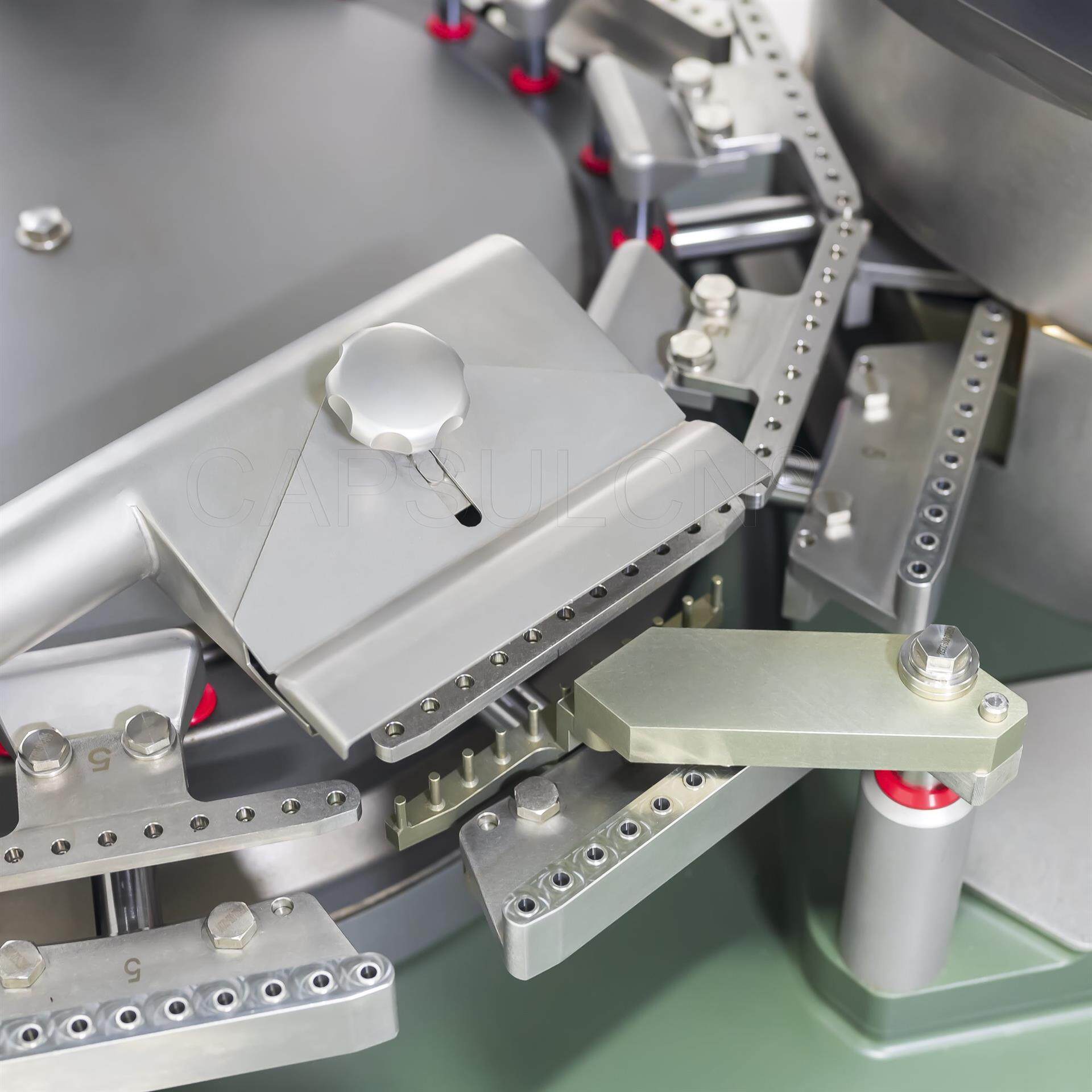

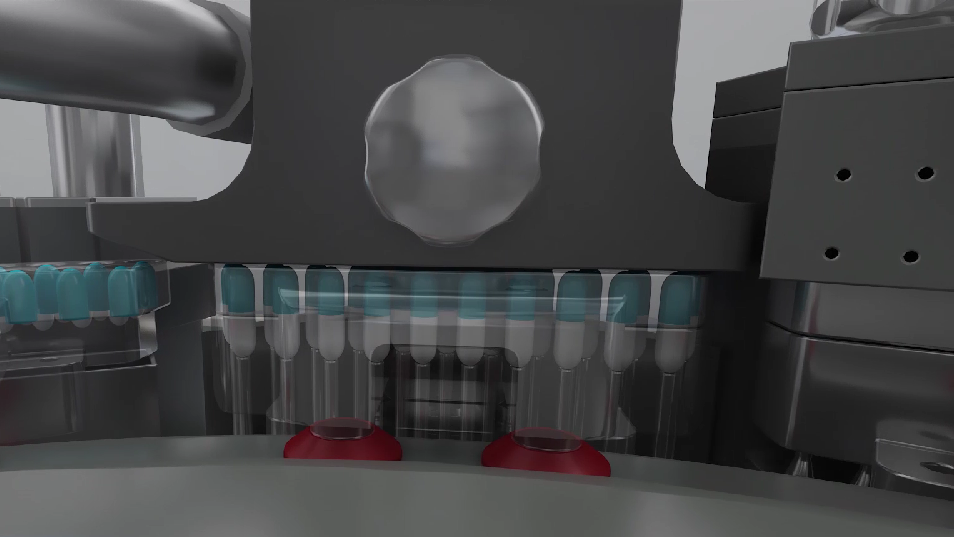

4. Closing Station

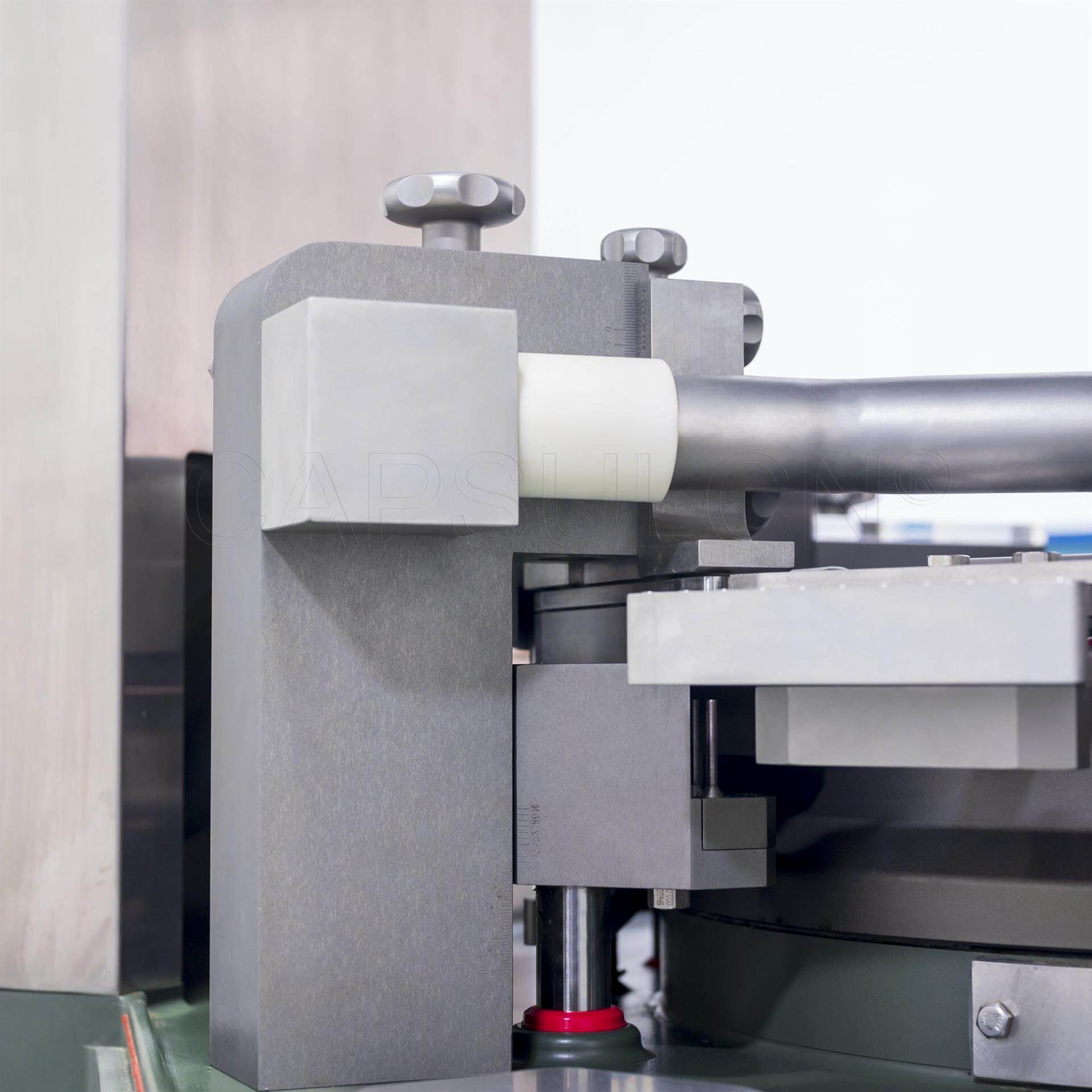

After faulty capsules are rejected, the segments move to the closing station. The capsule closing station consists of a counter bearing and closing pins. The counter bearing is located over the upper segment. The closing pins are oriented upward and installed at the bottom of the lower segment.

The closing station is responsible for locking the two halves of the filled capsule. This is done to prevent any leakage of the contents. During closing, a gap between the cap dome's top and the counter bearing's bottom surface should be adjusted appropriately. The gap ensures the capsule cap is vertically retained in the upper segment bore.

In the meantime, the closing pin moves upward to push the filled capsule body into the empty cap. The station uses concave-shaped pins to perform the function. The closing pins with concave tips prevent damage to the capsule bodies. This ensures the integrity and quality of the final product.

5. Discharge/Ejection Station

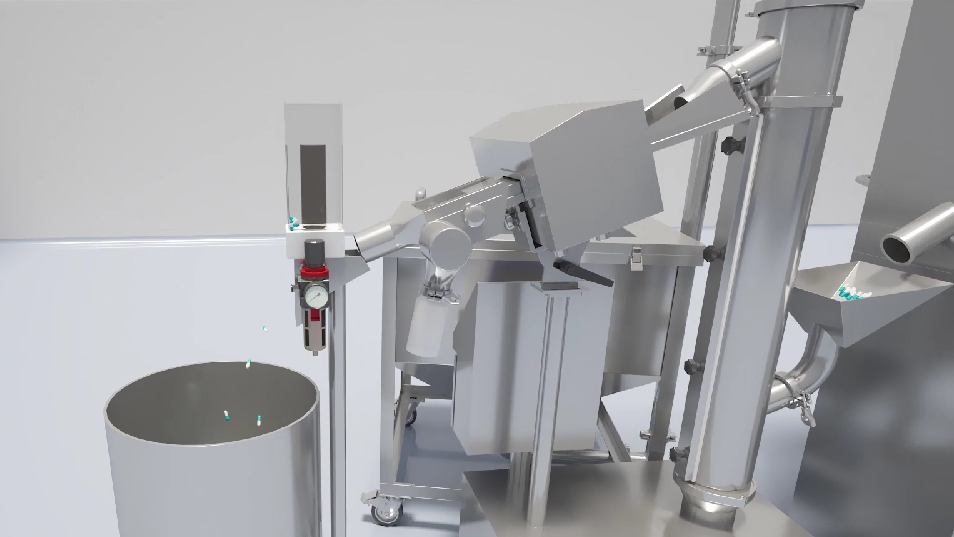

It is the second ejection station of an automatic capsule filling machine. After the filled capsules are closed and locked, the tooling carrying these capsules moves to this station.

The finished capsules then leave the machine through a discharge chute. After getting ejected from the machine, these capsules fall onto a collection box or conveyor belt for further processing.

The speed of the capsule discharge process can be adjusted to match the production speed of the filling machine. This ensures that the capsules are released at a consistent rate and do not pile up to cause jams or other issues.

Some automatic capsule filling machines may connect to a capsule polisher and metal detector after the discharge station. These devices work to detect and remove any excess powder or unwanted substances from the surface of the capsules before they are collected for packaging.

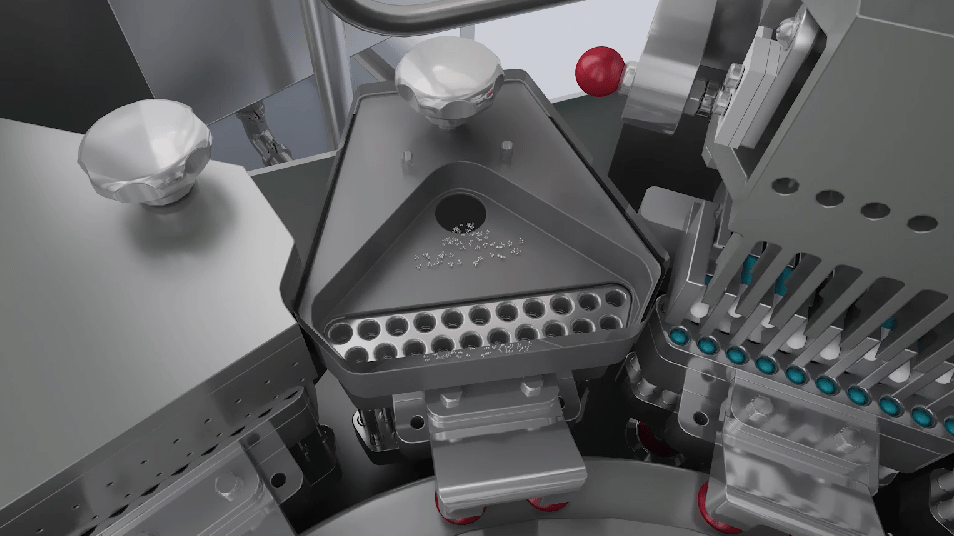

6. Cleaning Station

The cleaning station lies at the end of the capsule filling process. The station is equipped with a transparent acrylic dust cover. This allows you to observe what's going on in the station. It uses the vacuum system to remove any powder or debris from the segment bores.

The cleaning operation takes place before the next filling process. This ensures the capsule tooling is free of any leftover residue. Also, it helps minimize the risk of cross-contamination in future batches of empty capsules.

It's worth noting that not every automatic capsule cleaning station comes with a cleaning station. So, consult the capsule filling manufacturer or supplier before making the purchase.

Final Word

The above six stations play an important role in ensuring an accurate and efficient capsule filling process. From the orientation of empty capsules to the final cleaning operation, each station is designed to perform a specific task. They ensure that the capsules produced by your machine meet the highest standards of safety, efficacy, and purity.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche