Video

Introduction

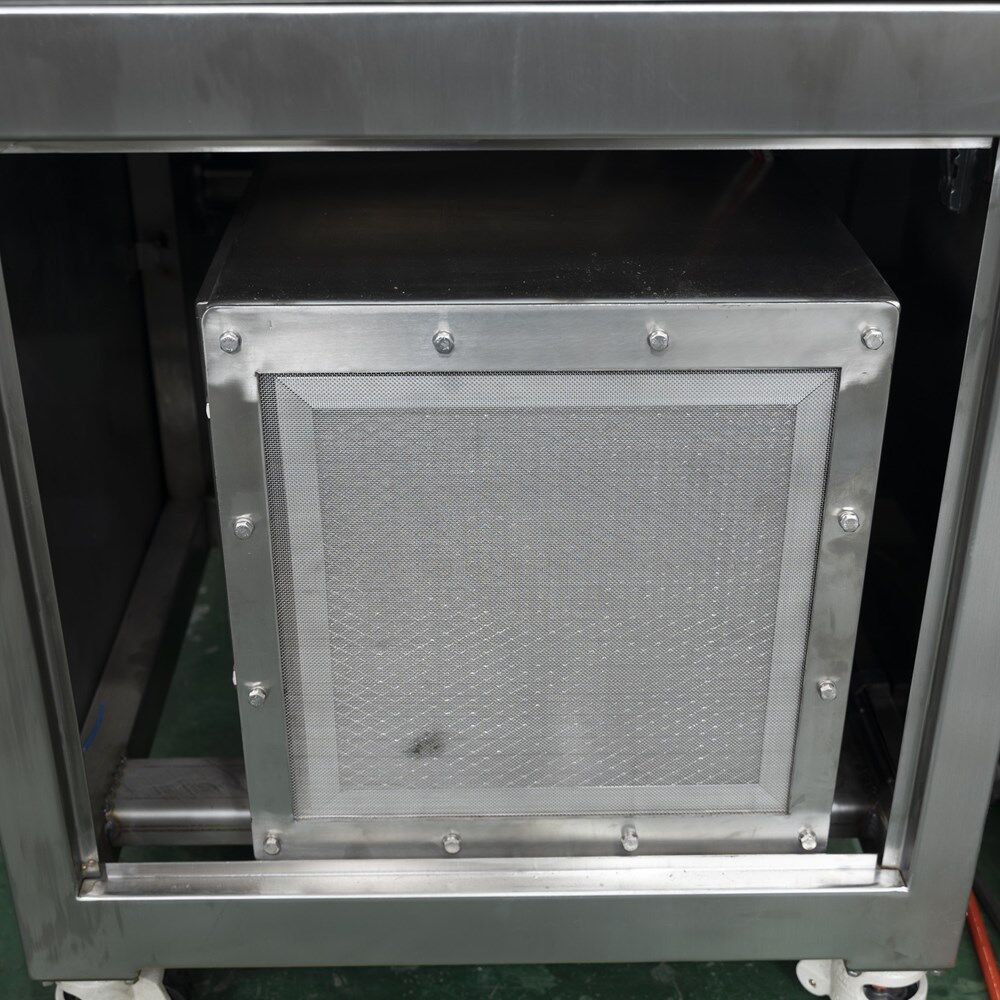

This equipment consists mainly of the main cabinet, the air inlet treatment system, the hopper dispersion chamber, the filter supplement collection chamber, the pulse dust removal mechanism, and the human-machine interface PLC control mechanism. Depending on the customer's process requirements, optional devices such as top spray, bottom spray, and side spray can be selected. All devices are designed for easy installation, requiring only the replacement of the corresponding supporting equipment to meet different process requirements.

Working Principles

This equipment excels in drying functionality. During the drying process, the material to be dried in the hopper is suspended in the airflow under the action of the induced draft fan. The particles come into complete contact with the hot air, achieving optimal heat exchange. This ensures uniform heating of the particles and the evaporation of excess moisture, resulting in effective drying. The drying speed can be adjusted by setting the inlet temperature and controlling the airflow rate according to the characteristics of the materials used in the formulation. The entire process ensures stable drying of the material, avoiding issues such as uneven heating and extended drying times, which can lead to color variations and performance differences in the final product.

Specifications

| Model | CFG-5 | |

|---|---|---|

| Production capacity | Top spray granulation drying | 0.5-5kg/time |

| Fan flow rate | 450m³/h | |

| Power voltage | 220V | |

| Fan power | 4.0kw | |

| Electric heating power | 6.5kw | |

| Compressed air | Pressure | 0.4-0.7Mpa |

| Consumption | 0.3m³/min | |

| Heating temperature | Room temp-110 PID temp control | |

| Material recovery rate | ≥99% | |

| Moisture content after drying | ≤5% | |

| Dimensions | 1200×1120×1930 | |

| Total machine weight | ≈600 | |

Feature

- Designed for small-scale experimental research and process trials in pharmaceuticals, food, and chemicals fields.

- Capable of drying and granulating using boiling drying or top spray granulation process.

- Offers flexibility, ease of use, and stable process operations.

- Widely used in product development and process research.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche