An Essential Guide for Selecting the Best Gummy Making Machine

Gummy candies have come a long way from being just a tasty treat! They've become so much more, and we can't get enough of them. They're everywhere in our society, and it's easy to see why! The magic begins in machines dedicated to producing these sweet confections.

Gummy production relies on machines that turn raw ingredients into candies we all know and enjoy. There are various gummy making machines on the market, so choosing one may be tricky! To choose correctly, consider factors like machine type, style, appearance and quality.

In this guide, we'll outline how to choose the ideal gummy-making machine and help you make more informed decisions.

What Are Gummy Making Machines?

Gummy making machines are machines that are designed to automate the production of gummy candies. You'll find them in places like candy factories, nutritional product factories, and kitchens. They can help you create candies in various shapes, sizes, and flavors in a more efficient way.

What Are the Different Types of Gummy Machines?

The secret to making gummy candy is all in the specialised machinery that turns liquid ingredients into delicious treats. Let's look at the different types of gummy candy machines and what they do in manufacturing.

Tabletop Gummy Machines

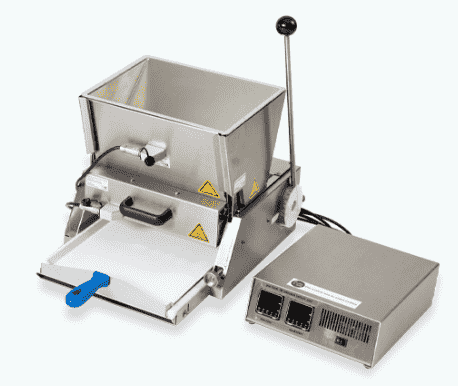

(Image Source:Savage Bros)

These small tabletop gummy machines are perfect for hobbyists or small-batch producers. They usually use manual or semi-automatic processes. They're great for testing different processes and switching between production capacities.

Semi-Automatic Gummy Machines

Semi-automatic gummy machines are somewhere between manual and fully automated production systems. They combine human involvement with automated processes, making them cost-efficient and controlled. They're great for medium-scale production environments. Since you need more room for customisation than you would with a fully automated system. Semi-auto machines give you more flexibility and customisation than fully automated ones.

Fully Automatic Gummy Machines

In industrial settings, fully automatic machines are the go-to choice for high-volume production. These machines are designed to cut down on human input while making sure the quality is always good and they can produce more. They come with all the latest automation tech to manage different parts of the production process. For example, mixing, cooking, moulding and packaging.

Gummy Depositor Machines

Gummy depositor machines help you get the consistency just right and dispense gummy mixture into moulds. If you have a large production line, depositing machines are great for making intricate shapes and designs quickly and easily. They use precise dosing technology to guarantee quality products with consistent dosing rates.

What Features Should the Best Gummy Manufacturing Equipment Have?

If you're looking to make delicious and consistent gummy candies, a high-quality gummy making machine is a must! When searching for the perfect equipment, keep an eye out for these key features:

- Maintaining a precise temperature. Controlling the temperature is key to getting the best texture and flavour in your products. A powerful mixer ensures all ingredients are blended evenly in each batch.

- Accurate dosing system. The precise dosing technology is used to reduce waste and boost productivity! It delivers the perfect amount of gummy mixture into moulds, every time.

- Built to last. The best gummy machine should be durable. It should made with high-quality materials that can handle continuous production. This way, you'll spend less time waiting for it to work and more time getting things done.

- Easy to clean and maintain. The gummy making machine should have user-friendly and versatile design. So, it's a cinch to keep clean and safe, and it'll save you time by reducing downtime.

- User-friendly interface. The controls are simple to use and the displays are easy to read, even for less experienced operators.

- Energy efficiency. Energy-efficient designs help cut operational costs and contribute to environmental sustainability. The machine has built-in safety features to keep operators safe and reduce the risk of accidents, so it's a safe place to work.

What to Consider when Selecting the Best Gummy Making Machine?

When choosing a gummy making machine, think about what you need to reach your production goals.

Production Scale

Your production needs will determine the type of machine you require:

- Small-scale: Tabletop machines are ideal for home-based businesses or small-scale commercial operations.

- Medium-scale: Semi-automatic machines combine manual and automated processes. They are ideal for growing gummy businesses.

- Large-scale: Fully automatic machines are designed for high-volume production in industrial settings.

Gummy Type

The type of gummy you produce will influence your machine choice:

- Gelatin gummies: If you're making gelatin gummies, make sure the machine can handle gelatin properties. This means precise temperature control and mixing.

- Starch-molded gummies: Look for machines designed for starch moulding processes. This means the gummy molds are dipped in starch before filling.

- Depositing gummies: When it comes to depositing gummies, choose a machine with accurate depositing. This ensures the gummy mixture is dosed precisely.

Budget

Consider your budget and long-term costs, including maintenance, energy consumption, and potential upgrades.

Manufacturer Reputation

Do your research and find a reputable gummy making equipment manufacturer. It should be known for producing high-quality machines and offering excellent customer support.

What Are Common Standards for Gummy Making Machine Production?

We all want to be sure that the gummy making machines we use are safe and reliable. And that's why manufacturers have to stick to very strict quality and safety standards.

- CE Marking: This certification shows that we follow EU safety, health and environmental rules.

- ISO 9001: This standard ensures consistent product quality. More importantly, customer satisfaction through effective quality management systems.

- ISO 14001: This standard promotes sustainable practices and reduces our impact on the environment. They make sure we're not harming the environment.

- FDA Regulations: The FDA has put together some helpful guidelines for safety and health. It has created guidelines for food processing equipment, including gummy making machines.

- HACCP: This standard makes sure your food is safe. It helps identify, assess, and control potential hazards.

- GMP (Good Manufacturing Practices): It helps you make sure everything is as it should be. GMP guidelines make sure products are safe and of the best quality.

Final Thoughts

The right gummy making machine can greatly impact your production efficiency and product quality. By thinking about what we have said here, you can make the right choice for your bussiness.

If you need any help or advice at all, just reach out to iPharMachine – our team of experts are always on hand to give you the assistance you need.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche