Coating Machine BYC-300: Structure Features and Operation Principles

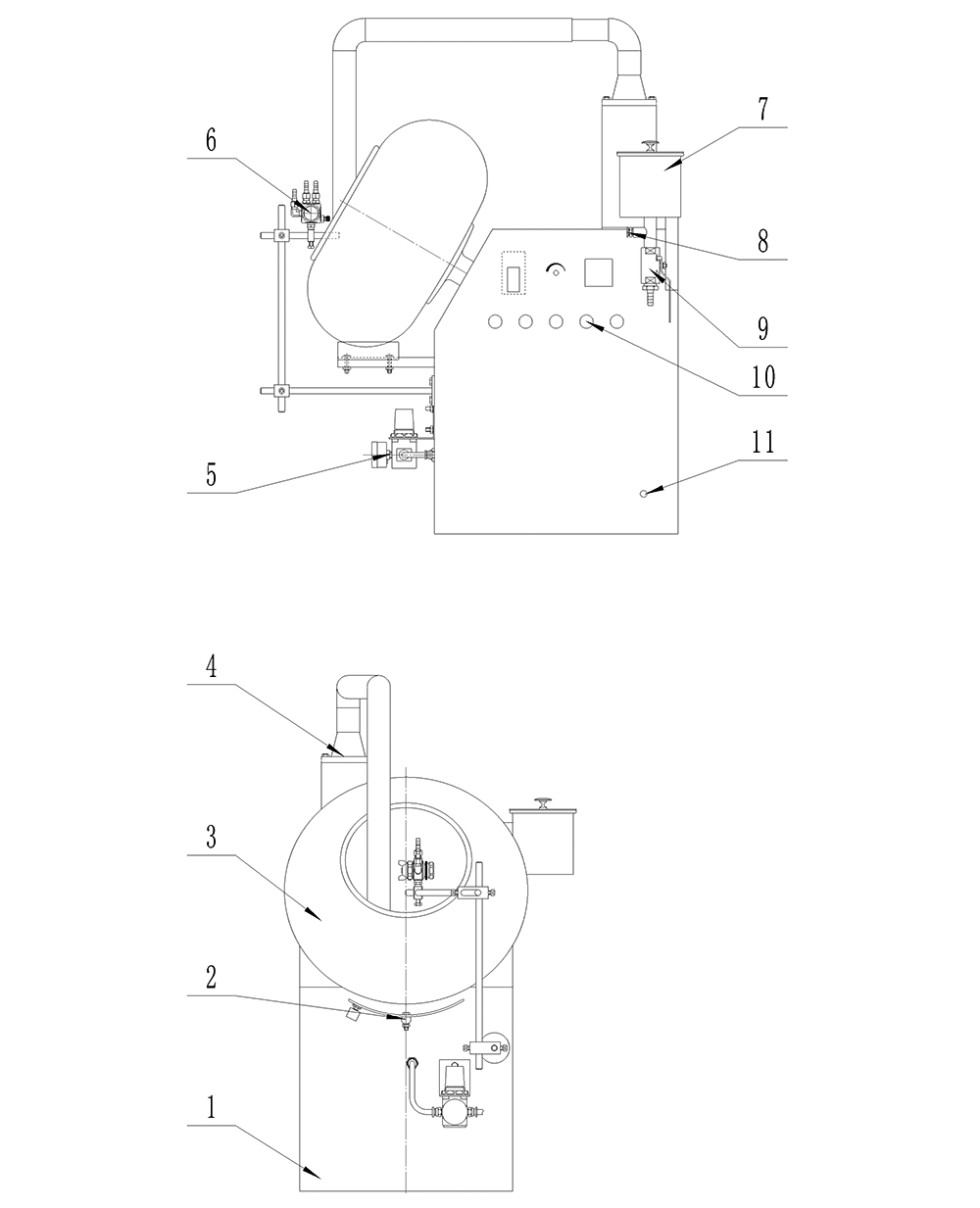

Machine Profile

- Machine body

- External heat

- Coating pot

- Internal heat device

- Liquid blasting control valve

- Spray gun and support

- Liquid container

- Coating liquid outlet

- Cleaning fluid tube outlet

- Operate button

- Compressed air inlet

Structure Features and Operation Principles

This Coating Machine BYC-300 is used to sugarcoat and film coat Chinese and Western tablets; it integrates strong power, weak power, hydraulic pressure and pneumatic. It consists of the host (original sugarcoating machine), controllable room temperature hot air system and automatic mist-jet propulsion. The main motor speed is controlled by frequency variation. During the process of high atomization airbrush work, it utilizes high pressure air flow to form negative pressure in the spray gun cavity. Under the role of atmosphere, coating liquid is sprayed to the surface of tablets. In the meantime, tablets continuously go on complex trace movement in the coating pot. It enables coating liquid to be evenly coated on the tablets. Controllable room temperature hot air dries the tablets to form sturdy, fine, complete and smooth surface film.

The machine is simple, easy to operate, smooth, bright, delicate, save auxiliary and convenient to maintain. It is the ideal choice for experimental equipment.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche