Exploring Continuous Band Sealer Parts and Their Functions

Continuous band sealers are a go-to option for sealing bags and pouches. They work by applying consistent heat to create an airtight seal on these packages. Continuous band sealers are entry-level heat sealing machines. They're easy to use, clean, and maintain. However, the premise is that you've gained knowledge of the machine parts.

Do you want to know your continuous band sealer better? Keep reading and explore your machine's critical parts and their functions.

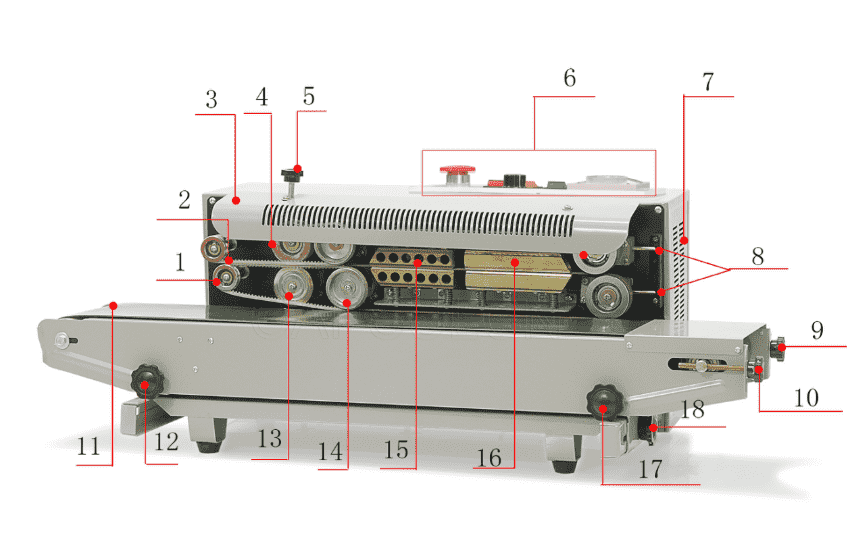

Continuous Band Sealer Diagram

Continuous band sealers are available for a range of applications. That's why there are many band sealers with specific features, such as inkjet printing, air suction, or gas flush. To make it easier for you to understand each part of a continuous band sealer, we will show you a diagram of the machine with the basic configuration.

| 1. Guide wheel | 2. Guide rubber belt | 3. Protective cover |

| 4. Embossing wheel | 5. Embossing wheel adjustment knob | 6. Control panel |

| 7. Air vent | 8. Embossing wheel adjustment knob | 9&10. Conveyor tension adjustment knobs |

|

11. Conveyor belt |

12&17. Conveyor height adjustment knobs |

13. Rubber wheel |

|

14. Drive wheel |

15. Cooling block |

16. Heating block |

|

18. X-axis conveyor position adjustment knobs |

||

What are the Essential Continuous Band Sealer Parts?

As shown in the above image, a standard continuous band sealer is made up of a variety of parts and components. Each plays an important role in the heat sealing process. In this section, let's look at how the major continuous band sealer parts work together to create a perfect seal.

1. Conveyor Belt

Continuous band sealers are also known as continuous belt sealers. The conveyor belt plays a big part in the band sealer. The belt used in this conveying system is typically made of high-quality PVC on the front side and nylon fabric on the back.

The conveyor belt is designed to guide and transport bags or pouches through the band sealer in a continuous fashion. This component ensures that every package runs through the sealing section at a certain speed. Also, it allows bags or pouches to receive uniform heat and pressure for forming a hermetic seal.

2. Control Panel

The control panel is one of the most important continuous band sealer parts. It allows operators to adjust conveyor speed, temperature, and other settings. On this panel, there is a range of rocker switches that are used to activate the power, heat, and fan. The temperature can be controlled using either a knob or a digital keypad.

In addition to facilitating the operation of the machine, the control panel features a critical mechanism - an emergency stop button. This button allows for stopping the machine immediately in case of any emergency. This guarantees the safety of the machine and operator during the continuous sealing process.

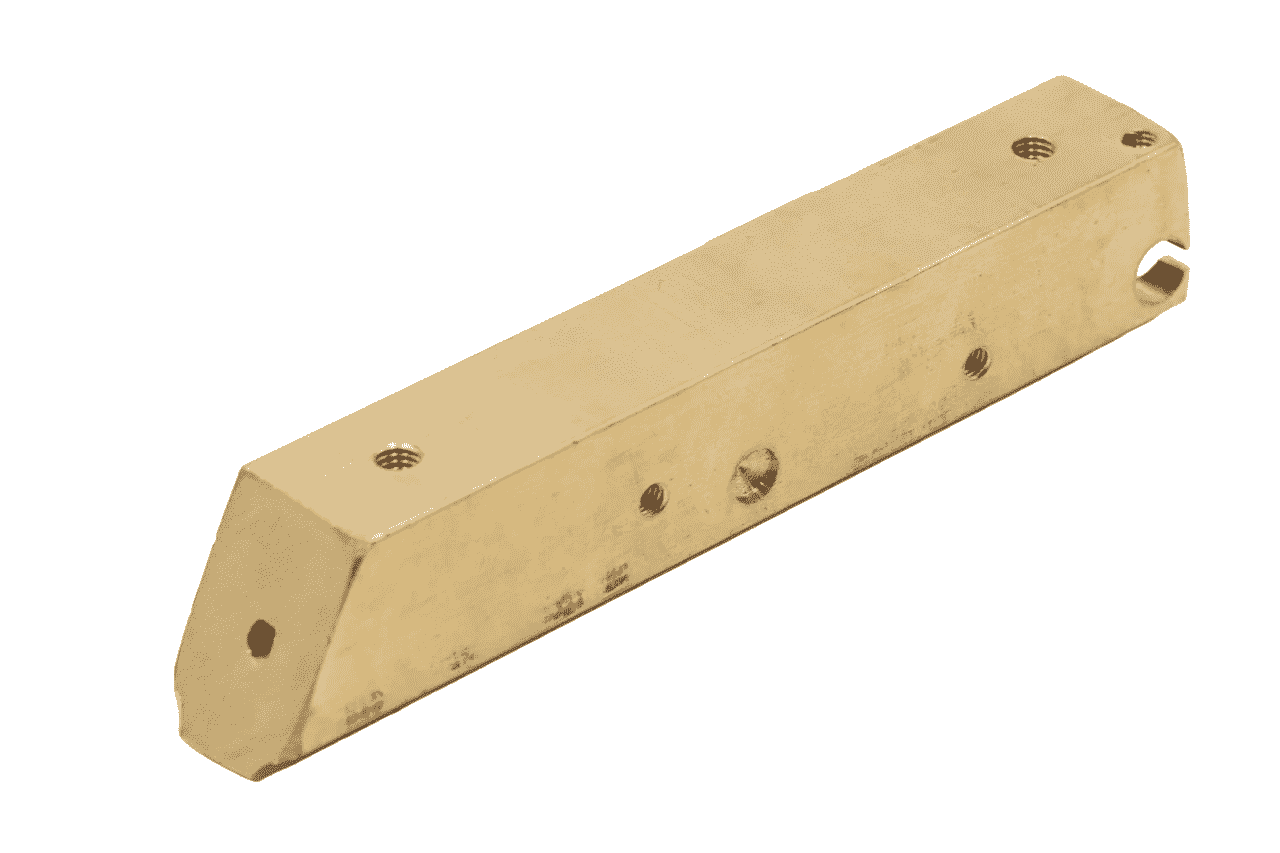

3. Heating Block

The heating block is one of the critical continuous band sealer parts. A band sealer includes a pair of lower and upper heating blocks. These blocks are usually made of premium copper.

The heat in a continuous band sealer is generated by heating elements. These blocks typically hold the heat transferred from the heating elements to melt the packaging material and create an even, airtight seal.

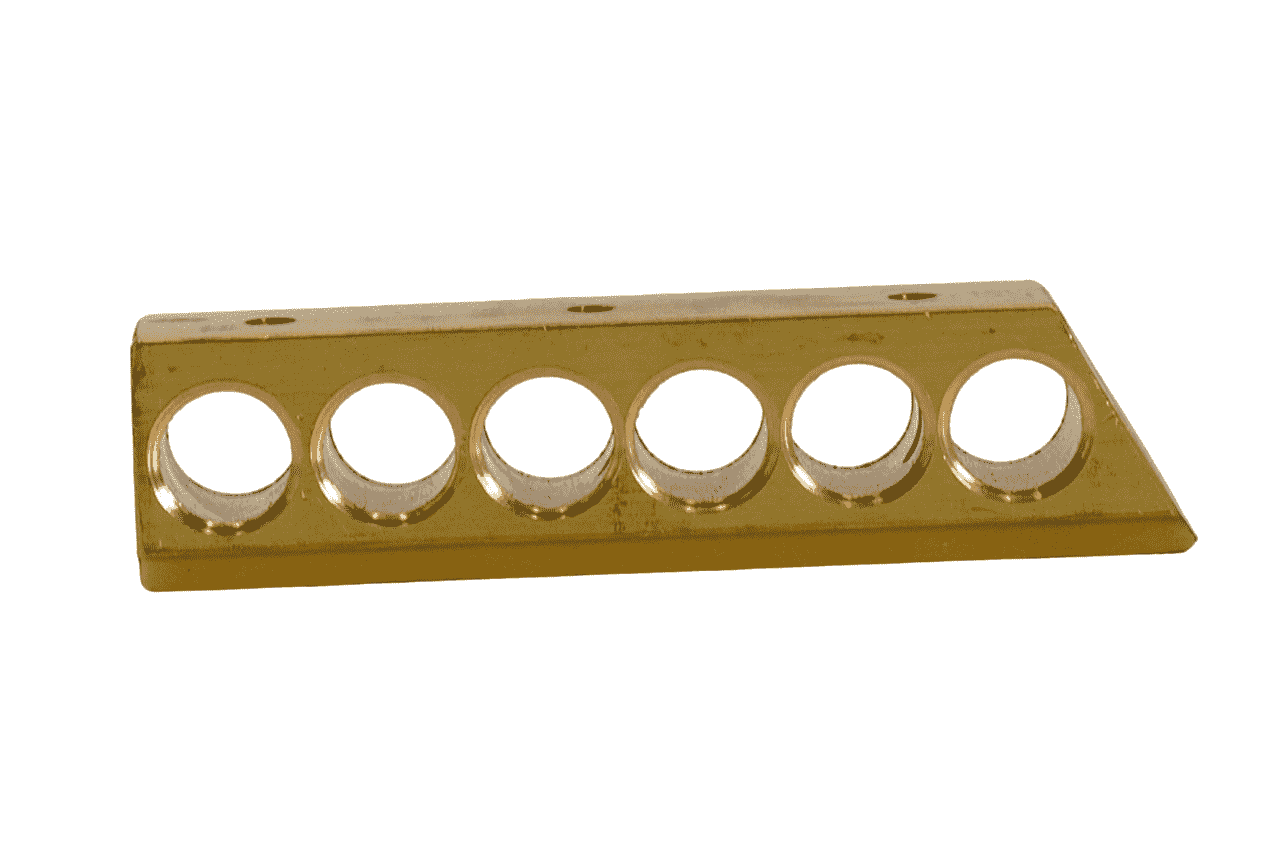

4. Cooling Block

As the heated material is prone to deformation, all continuous band sealers feature a pair of lower and upper cooling blocks to cool down the heated packages. These blocks are also made of pure copper. Unlike heating blocks, cooling blocks have hole designs. This facilitates effective heat dissipation to ensure the hot seal sets quickly.

When the sealed bags or pouches pass through the heating blocks, the cooling blocks are responsible for quickly absorbing the heat of the seal. This cooling process helps form a flat, secure seal.

5. Cooling Fan

In addition to cooling blocks, a cooling fan is another essential component to help create a perfect seal. The cooling fan cools the heat on the sealed bags or pouches that travel through the cooling blocks. This component works by directing a stream of cool air onto the hot seal to prevent damage to the package caused by overheating.

The cooling fan also dissipates heat generated during sealing to protect the machine. This ensures the optimal performance of all continuous band sealer parts.

6. Guide Belts

The guide belts used in a continuous band sealer include one sealing belt and one drive belt. The former is typically made with Teflon, and the latter is crafted from rubber. Both belts are responsible for guiding bags or pouches through the sealing machine.

In addition to positioning the package precisely for sealing, the Teflon belt offers a non-stick, temperature-controlled surface for the package passing through the heating and cooling blocks. The rubber belt wraps around the drive wheel to create traction and friction to move the sealed package out of the machine.

7. Embossing Wheel, Rubber Wheel, Drive Wheel, and Driven Wheel

Wheels are important continuous band sealer parts. Take a standard model as an example. The band sealer typically consists of two driven wheels, two drive wheels, one embossing wheel, one rubber wheel, and a pair of guide wheels.

The drive and driven wheels provide traction to move the packaging through the machine. They also apply pressure onto the seal to make it even and secure. The embossing wheel can be customed to create the desired imprints on the package.

8. Adjustment Knobs

Continuous band sealers feature versatility and flexibility as they can be adjusted as needed. A standard continuous band sealer typically comes with multiple adjustment knobs. These knobs allow operators to adjust the position and tension of the conveyor belt and various wheels without tools. This ensures the machine accommodates different sealing directions and diverse package sizes.

9. Circuit Breaker

The circuit breaker is one of the essential continuous band sealer parts. It's a safety device used to protect the electrical circuit of your band sealer. The damage can be caused by overload, overcurrent, or short circuit. The circuit breaker automatically cuts off the current flow of an overloaded electrical circuit. This helps prevent damage to your continuous band sealer and reduces the fire risk.

10. Protective Cover

When operating a continuous band sealer, personal safety is a top priority. Safety features such as a protective cover is a must-have. This safety guard provides a shield around the heat sealing section. It ensures the safety of operators who have accidental contact with the heated components and moving parts.

The Bottom Line

Understanding the essential continuous band sealer parts can greatly help you handle the machine more easily, identify and troubleshoot unexpected issues, and keep it in tip-top shape.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche