PVC vs. PVDC: Which is Right for Your Pharmaceutical Packaging?

Are you having trouble finding the perfect plastic for your pharmaceutical production line? You're not the only one! The market offers PVC and PVDC. It probably leaves you wondering, "Which one should I choose?" It must be hard to pick the right material if you don’t know their differences.

Plastic is something we can't do without. It's used in strong industrial pipes, important building parts, and necessary packaging. When it comes to plastic, you usually have to choose between PVC and PVDC. They are two materials that are made up of different things.

We're going to talk about how they're made, the good and bad parts of each, and how they're used in the real world. So, keep reading and let's figure out the main differences between PVC and PVDC.

What Is PVC?

PVC is short for polyvinyl chloride. It is a thermoplastic material. At its core, it's made from resin, which gives it its signature durability and strength. It's also known for its impressive resistance to all sorts of inorganic chemicals. But here's the cool part: PVC is incredibly versatile.

You can add different substances to it. And suddenly, you can get a material with better elasticity, fire-retardant properties, or even microbe prevention. And because it's so cost-effective, you'll find PVC popping up everywhere, from construction and manufacturing to medical applications.

What Is PVDC?

PVDC stands for Polyvinylidene chloride. Ralph Wiley, a chemist, invented this synthetic plastic polymer in 1933. You might have seen it in cling films used for food packaging, but it's now often replaced by materials like low-density polyethylene. However, PVDC is still used as a high-performance barrier coating. It's often used in other plastics to make them less permeable to oxygen, water, and flavor molecules, which makes products last longer and look better.

You can find PVDC in many different things, like household cleaning supplies, doll hair, fishnets, and photographic films. So, even though both are plastics, they're used for very different things.

How Do the Components of PVC and PVDC Differ?

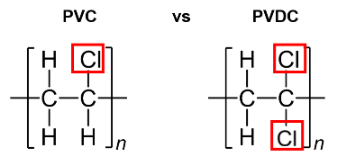

PVC, or polyvinyl chloride, is made through a process called polymerization, where tiny vinyl chloride molecules link up to form a long chain of repeating chloroethene units.Think of it as building a plastic chain with single chlorine atom building blocks, represented by the formula (C₂H₃Cl).

Like PVC, PVDC is also made through a process called polymerization, but it uses a different type of molecule, called vinylidene chloride, to make it. The repeating unit of PVDC is represented by the formula (CH₂=CCl₂). The key difference between the two is that PVDC has twice the chlorine of PVC. This extra chlorine makes a big difference in how well it can protect things, especially from water or air.

What Are the Different Advantages of PVC and PVDC?

We've talked about the compositional differences between PVC and PVDC, but what about their real-world benefits? Let's get down to business.

PVC Advantages

Simple to work with - PVC is easy to mold and shape because it's not hard to soften. This makes it great for making packaging that needs to be bent or shaped in a certain way. You can think of it as the flexible friend of the world of plastics.

Budget-friendly - PVC is the more affordable option compared to PVDC, which makes it a popular choice for manufacturers who want to save money.

Durable - PVC is strong and long-lasting. It doesn't break easily, doesn't rust, and can handle so many different weather conditions. It is great for building materials.

PVDC Advantages

- Offer great protection - Because of its high chlorine content, PVDC is perfect for keeping out oxygen, water vapour, smells. So, if you're looking to protect your products from the outside world, PVDC is the way to go.

- It can handle the heat - PVDC can endure very high temperatures. And it melts at a higher temperature than PVC. So, it’s ideal for packages that need to withstand very high temperatures.

- Resistant to chemicals - PVDC doesn't break down easily when acids, bases, and oxidizing agents happen, so your products won't be destroyed by them.

- Make products last longer - PVDC can keep products fresh for longer. It's a good choice for products that go bad easily, like moisture-sensitive drugs and food. PVDC's special properties help to prevent spoilage.

What Are the Different Disadvantages of PVC and PVDC?

No material is perfect. So both PVC and PVDC have drawbacks. It’s important to understand them so you can make informed choices.

PVC Disadvantages

- It doesn't offer a strong barrier - You remember the lower chlorine content? This means that PVC is not very effective at blocking out pollutants. It can resist alcohol, bases, UV, and acids, but not very well. So, if you need serious protection, PVC isn't the best choice.

- Short lifespan - PVC is a good material to package products that don't last very long. For long-term storage of fragile items, it's not ideal.

- It is not sustainable - PVC can contain harmful additives like phthalates, lead, and cadmium. These additives are dangerous to human health and contribute to environmental pollution, especially when the PVC is burned.

- It doesn't withstand high temperatures well - Compared to PVDC, PVC is more sensitive to heat. It can't handle extreme temperatures

PVDC Disadvantages

- It has only a few uses - PVDC is less flexible than PVC, so it can't be shaped or molded as easily. It's often used for coatings and coverings, which limits how it can be used.

- Pricey - It's expensive because of its superior barrier properties. PVDC costs much more than PVC.

- You cannot recycle it - PVDC's high chlorine content, which gives it strength, also makes it difficult to recycle. During processing, it releases more chlorine and toxins, reducing its sustainability and making disposal hard. It decomposes very slowly.

How Do Machines for Processing PVC and PVDC Differ?

Some machines can process both PVC and PVDC. But applications and configurations differ. Below are some common machines used to process PVC and PVDC.

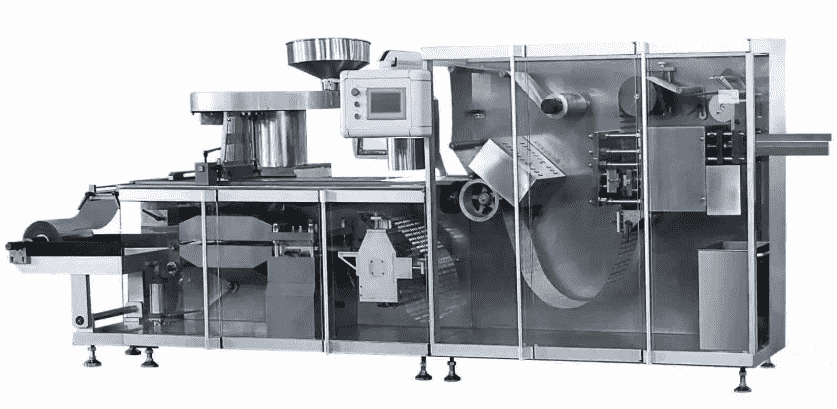

1. Blister Packaging Machine

Blister packaging machines can process PVC, but they're really designed for PVDC because of its top-notch barrier properties. This is a must for pharmaceutical packaging. They contain parts like a main frame, film holder, PLC interface, heating system, and a film pulling and molding mechanism. They form blisters, fill them with tablets or capsules, and seal them with aluminum foil.

Blister packaging machines can process PVC, but they're really designed for PVDC because of its top-notch barrier properties. This is a must for pharmaceutical packaging. They contain parts like a main frame, film holder, PLC interface, heating system, and a film pulling and molding mechanism. They form blisters, fill them with tablets or capsules, and seal them with aluminum foil.

2. Pouch Packaging Machine

Pouch packaging machines are versatile. They can handle both PVC and PVDC for flexible packaging such as pouches and sachets. These machines can do a lot at once: unwinding film, forming bags, filling, and sealing. You can use them to package all kinds of products, like powders, granules, and liquids, in the food, pharmaceutical, and chemical industries.

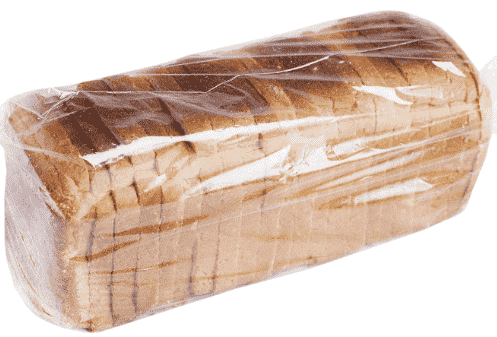

3. Vacuum Packaging Machine

Vacuum packaging machines take air out of packages to make products last longer. You can use them with both PVC and PVDC films and wraps. They're great for packaging food products in places like bakeries, restaurants, markets, and homes.

The End

In today's fast-paced world, we're increasingly turning away from traditional materials like metal, wood, and ceramics. This makes the importance of PVC and PVDC clear. They're used in food, medicine, and many other industries.

But, as we've seen, the details make all the difference. It's essential to understand these differences when choosing the right material for your specific needs. If you want to learn more or find the right equipment to process PVC and PVDC, check out our website. Thanks for joining us on this journey!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche