How To Perform A Dosing Disc Thickness Calculation For Capsule Fillers?

The dosing system lies at the heart of the operation for tamping pin capsule filling machines. Research has shown that 90% of the nonconformities may be brought on by this system. So, it is crucial to understand this part to attain optimal quality and weight control.

The dosing system typically consists of a powder bowl, tamping pins, a tamping ring, and a dosing disc. To effectively control the tamp filling process, you need to learn about an array of variables. Among them, the dosing disc thickness should never be overlooked.

1. What Is A Dosing Disc?

This tooling is a polished, stainless steel plate in a tamping pin capsule filling machine. It typically comes with six sets of holes. The five sets are for compressing the powder to form a plug. The rest works with the tamping pin to eject the compressed plug into the empty capsule body.

2. Why Dose Dosing Disc Thickness Matter?

This machine part is available in a range of thicknesses to fit various production needs. Yet when we talk about the dosing disc thickness, we're also talking about its cavity volume.

A successful tamp filling process has a lot to do with the relationship between the fill weight, the dosing disc cavity volume, and the tamping pressure.

If the cavity volume is too low for the desired fill weight, it will be difficult to create the necessary pressure for powder compression. While if the volume is too high, the applied pressure might not be sufficient to form a coherent plug for a smooth transfer to the capsule body.

So, choosing the right disc is vital to obtain the target fill weight and dose uniformity.

3. Dosing Disc Thickness Calculation

If you wonder how to calculate the dosing disc thickness, here are some parameters that may help you out.

1) Tamping Depth of the Pins

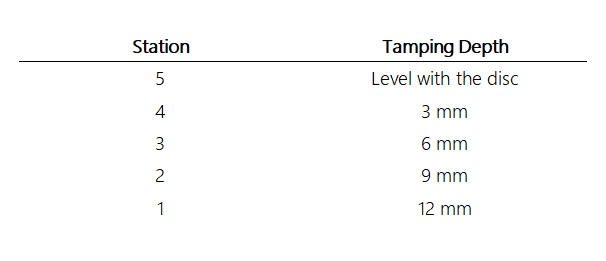

As we mentioned earlier, the tamping pin capsule filling machine uses the dosing disc and the tamping pins to create powder plugs. In a five-stage process, the dosing disc thickness is closely related to the tamping depth of the pins.

The table above shows an example. To achieve uniform doses, set the tamping depth in each preceding station 2 to 3 mm deeper. These data may help you work out the thickness that suits you best.

2) Capsule Sizes

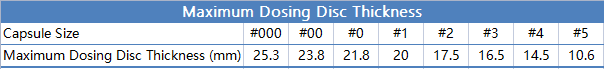

Most modern capsule filling machines are designed to fill a plurality of formulations into capsules in different standard sizes.

Through the dosing disc thickness calculation, we created the table below. It will help you choose an appropriate disc for the specific capsule size.

3) Formulation Types

The tamping pin encapsulation machines are capable of filling various types of formulations. However, the density of different formulations will vary.

Let us suppose, for example, that you're going to fill two types of formulations at the same weight. One is heavy and bulky, while the other is light and fluffy. Evidently, the dosing disc thicknesses for these two products must differ. Research shows that the tamp filling machine is more effective in compressing bulky materials into a given size.

So, it would be best if you considered the formulations before choosing the disc.

4. Wrap-Up

In a nutshell, the right dosing disc thickness can greatly contribute to an automatic capsule filling machine's filling accuracy, flexibility, and reliability. Of course, the dosing disc thickness calculation will be performed at the equipment manufacturing facility. So, no worries. All you need to do is bring up all your production needs to your vendor.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche