Merits and Demerits of Double Cone Blender: A Detailed Guide

Do you feel frustrated when your powders or granules consistently fail to be uniformly mixed? If you're looking to get a final product that satisfies customer needs and meets regulatory standards, achieving a perfectly uniform mixture of materials is essential.

To do that, you need a low-impact mixing mechanism: choosing a double cone blender will be a smart move for your recipes that require gentle handling. So, what are the benefits of using such a blender?

In this article, we'll walk you through the advantages and disadvantages of double cone blender. And before investing in a blender, you may also want to learn the details of different pharmaceutical blender types.

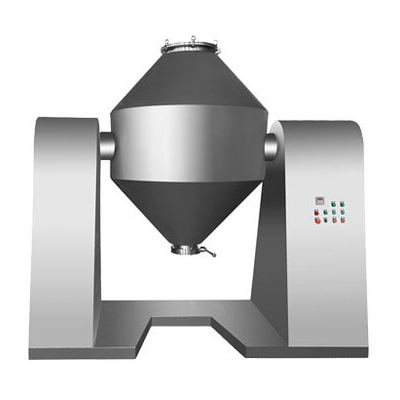

A brief intro to the double cone blender

What is a double cone blender? It is a standard tumble blender working best for materials that need to be gently tumbled.

The double cone blender features a unique design. As the name of the blender suggests, the mixing vessel is made up of two cone-shaped parts at both ends and a cylindrical section in between. The mixing vessel is fully welded and polished, allowing the particles inside to tumble freely.

So, how does a double cone blender work? Its working principle is actually quite simple.

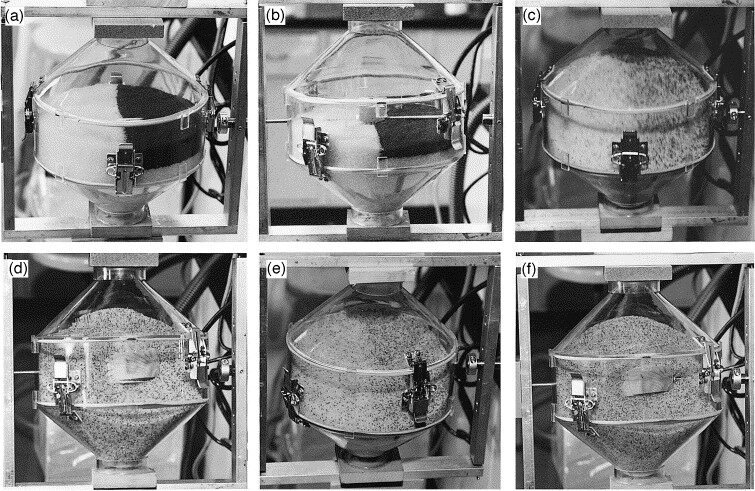

(Image Source: ScienceDirect.com)

Particles to be blended are fed into the blender manually or using vacuum suction. The blending vessel needs to be filled with two-thirds of its total volume. The particles are intermixed as the double cone performs a 360-degree rotation. Depending on the properties of the materials, the blending typically takes 10 to 15 minutes to achieve homogeneous mixtures.

This efficient piece of equipment is widely used for the dry mixing of free-flowing solids such as powders and granules. It's capable of producing homogeneous mixtures by blending 2 to 5 ingredients.

This blender is a versatile machine that can be used in various industries like pharmaceuticals, food, cosmetics, chemicals, plastics, fertilizers, etc.

What are the advantages and disadvantages of double cone blender?

What materials are you going to mix? The double cone blender uses a vessel that rotates or tumbles to thoroughly blend the ingredients inside. This is what makes it the best option for fragile and abrasive particles.

Now, let's get back to the main topic. Why should you use a double cone blender?

The advantages of double cone blender

1. The double cone-shaped sections at both ends enable reliable powder discharge and homogeneous mix results.

2. The statically balanced double cone prevents undue strain on the motor and gearbox.

3. The double-cone design makes it simple to load and discharge.

4. Material loading and discharge methods are segregated in such a blender to avoid cross-contamination.

5. Depending on the characteristics of the ingredients to be blended, the blender offers a variety of mixing structures for you to choose from.

6. To prevent corrosion and contamination, all contact parts are constructed from stainless steel.

7. The blender can process massive amounts of particles.

8. The blender is a flexible device with a fully-enclosed construction for effective, consistent tumble mixing.

9. The blender only requires a small footprint due to its compact design and construction.

10. Low-maintenance, easy to clean, and simple to use.

11. The blender can work with a variety of additional support devices, including hoppers, loading systems, and spray systems.

As every coin has two sides, likewise, the double cone blender also has its advantages and disadvantages. Let's now talk about the drawbacks of the equipment.

The disadvantages of double cone blender

1. This type of blender is not fully automated, so it requires manual handling, such as loading materials and opening the butterfly valve for discharge.

2. When it comes to manual intervention, you shall ensure the operator is well-trained to follow the operating instructions for proper setup, use, and maintenance.

3. This piece of equipment is not suited for blending fine particles.

4. Powders or granules varying in size, including fine and large particles, can't be mixed effectively due to the low shearing force of the blender.

5. The blender is not easy to move around due to its weight.

6. Considering its 360-degree rotation, the blender cannot be installed in small rooms with low ceilings.

7. Most blenders are not equipped with safety guards, so safety precautions must be taken when using the equipment.

Conclusion

Having a clear idea of the double cone blender advantages and disadvantages can guide you to finding the best equipment to fit your production needs. At iPharMachine, we offer the quality double cone mixer that can be a great addition to your business.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche