Double Cone Blender Parts, Principle and Diagram

The tumble blending technique has been used to mix powers, granules, and other free-flowing solids for over a hundred years. This approach is still widely used in modern times.

The tumble blending equipment, also known as a tumble blender, is available in a number of different styles, such as the twin shell blender, the double cone blender, and the slant-cone design.

Today we will focus on the double cone blender. This article is going to explore the construction of double cone blender, as well as its working principle, diagram, specifications, and other things you should know about.

Construction of double cone blender

Double cone blenders use a low-impact way to handle abrasive or sensitive solids. This makes it possible to create a gentle, repeatable mixing process that can keep the product's physical properties.

Achieving a homogeneous blend can't do without a practical equipment design. Let's now take a look at the construction of double cone blender.

A double cone blender typically features a mixing vessel made of stainless steel. The mixing vessel is constructed of two conical pieces that are welded together. Both ends of the vessel have openings, one for material feeding and the other for material discharge.

The blender is also fully welded and polished on the inside. Thanks to the unique double-cone shape, the equipment has no dead angles inside the mixing vessel, allowing for easy and quick discharge.

Some double cone blenders boast paddle-shaped baffles or an intensifier bar inside the mixing vessel to help mix materials better.

Further, in a double cone blender, a motor and a gearbox work together to give the blender the best speed for mixing.

In the construction of double cone blender, all contact parts are made of stainless steel or food-grade materials to create a safe, hygienic space for the mixing process. The GMP-compliant design makes the blender easy to clean and maintain.

Read more: Advantages and Disadvantages of Double Cone Blender

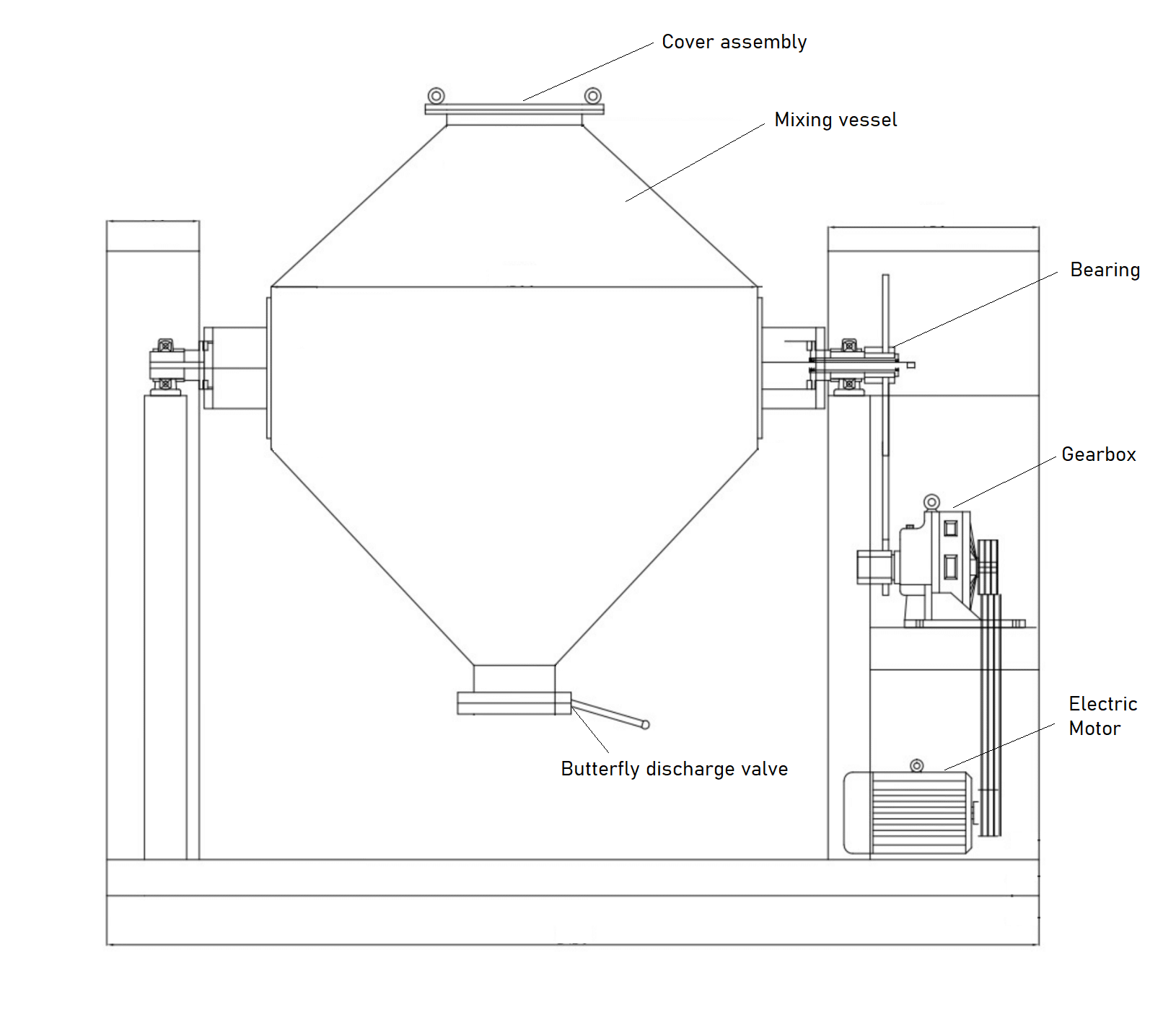

Double cone blender diagram

Let me guess - You might be wondering what a double cone blender looks like. Here's a diagram that will give you a better idea of the construction of double cone blender.

Double cone blender parts

As you can see, a typical double cone blender consists of the major parts shown in the diagram above.

1. Cover assembly

The cover assembly functions as a feed inlet of the double cone blender. This manually operated component can be locked to be dust-tight, preventing cross-contamination.

2. Mixing vessel

This component is one of the most important double cone blender parts. It is where the blending process takes place. The mixing vessel rotates on a horizontal axis. It takes advantage of the force of gravity to produce a cascading action, enabling materials within the structure to tumble.

Depending on the ingredients to be blended, the mixing vessel can be fitted with paddle-shaped baffles or an intensifier bar as and when required to break up large agglomerates.

3. Butterfly discharge valve

The blended material leaves the machine from the discharge port. This component features a hermetically-sealed butterfly valve. The valve can be designed to be manually operated, pneumatically controlled, or automatically opened according to your needs.

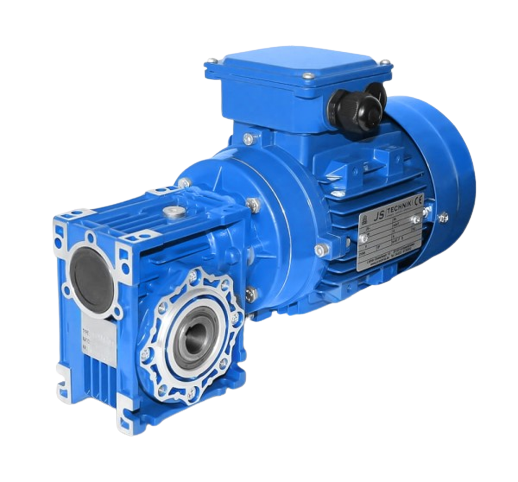

4. Electric motor and gearbox

The double cone blender is driven by an electric motor coupled with a gearbox. This assembly serves the purpose of regulating the overall speed of the system.

5. Control panel

The control panel consists of blending start/stop, jog/run, power indicator, emergency stop, and timer settings functions. This assembly allows you to easily operate the double cone blender.

Double cone blender principle

If you've read this far, you might have a rough idea of the double cone blender parts. Then you may wonder how does a double cone blender work?

Actually, the equipment works on a straightforward principle.

Material to be blended is fed into the mixing vessel through the feed inlet and is filled up to 50–60% of the vessel's total volume.

With the assistance of the electric motor, the mixing vessel is given the ability to rotate at a speed that ranges from approximately 35 to 100 revolutions per minute.

The material is moved into opposing ends of the mixing vessel as the double cone blender rotates. The material is separated and gathered as a result of this movement, which finally results in the ingredients being mixed homogeneously.

After the blender rotates for a set amount of time, the final product leaves from the butterfly discharge valve fitted at the bottom.

Double cone blender application

Double cone blenders are a solid option to achieve a homogeneous mixture of solid-solid or solid-liquid ingredients.

They are now widely used in the manufacture of products for industries including pharmaceutical, nutraceutical, food, chemical, cosmetics, detergents, fertilizers, and plastics.

With the help of a vacuum, double cone blenders can be used to dry free-flowing solids evenly at a certain temperature. They can also be installed with a spray system for coating if needed. Most of these units are employed in the pharmaceutical and chemical industries.

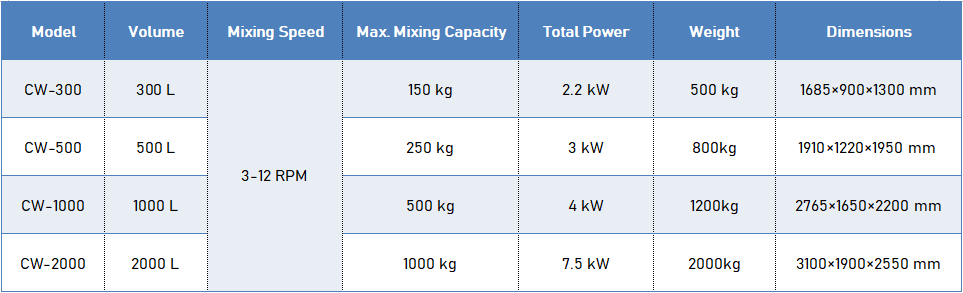

Double cone blender specification

At iPharMachine, we offer a comprehensive range of double cone blenders to choose from. Below is our double cone blender specification chart that can help you find the right equipment.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche