Video

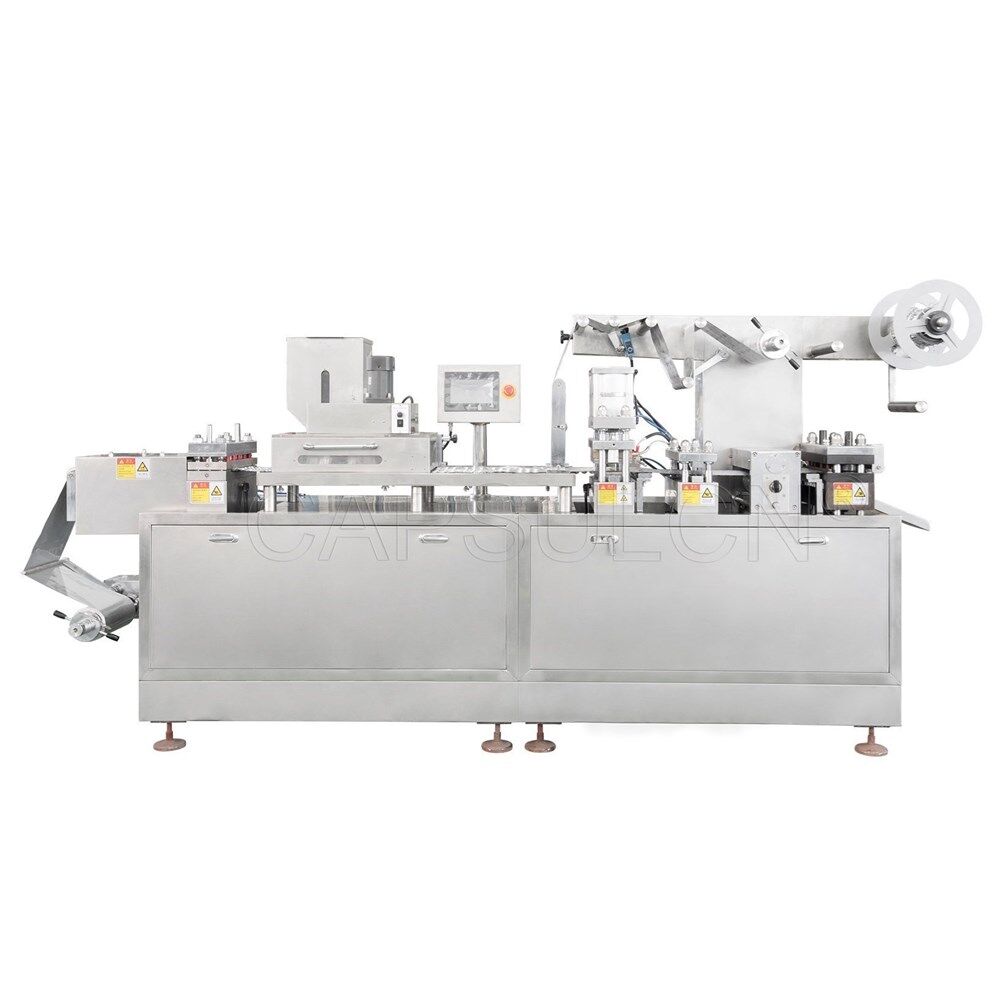

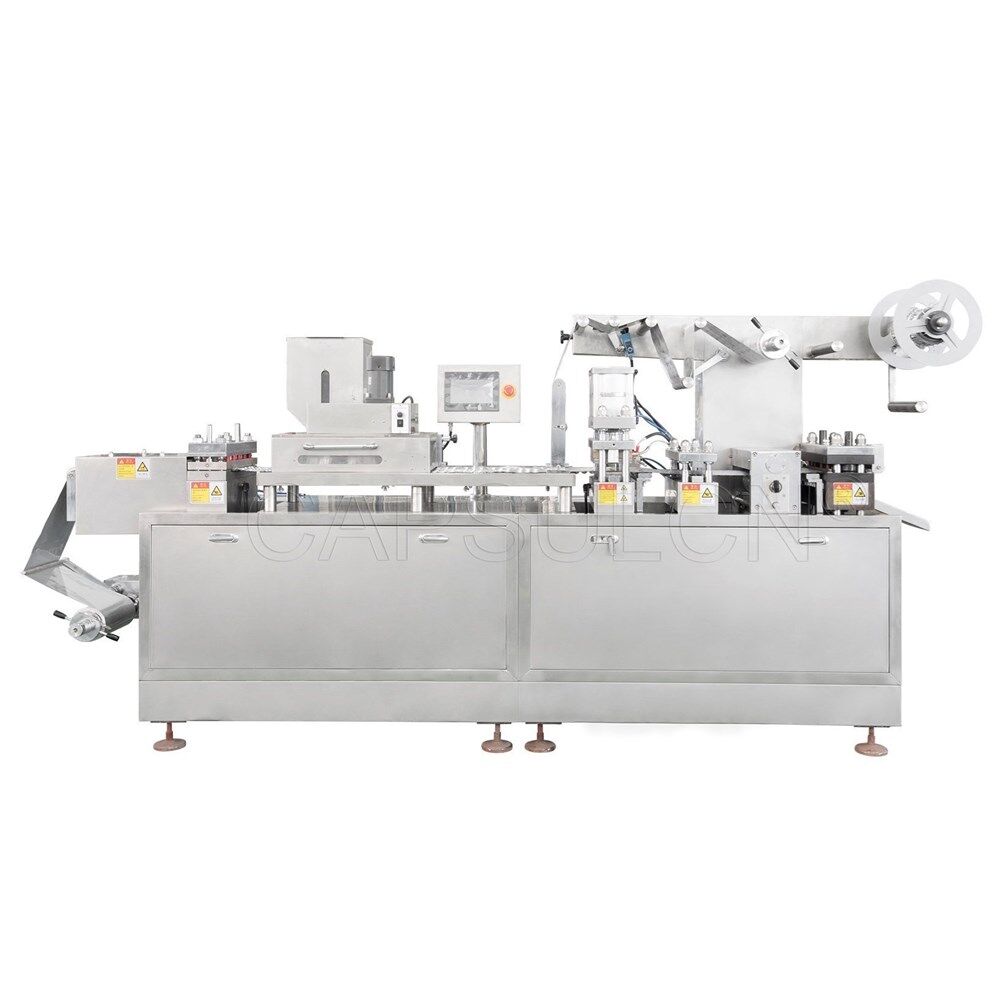

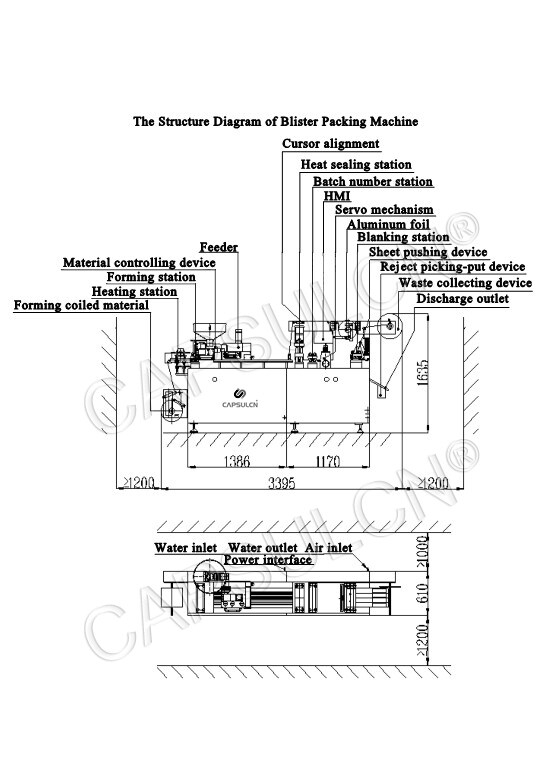

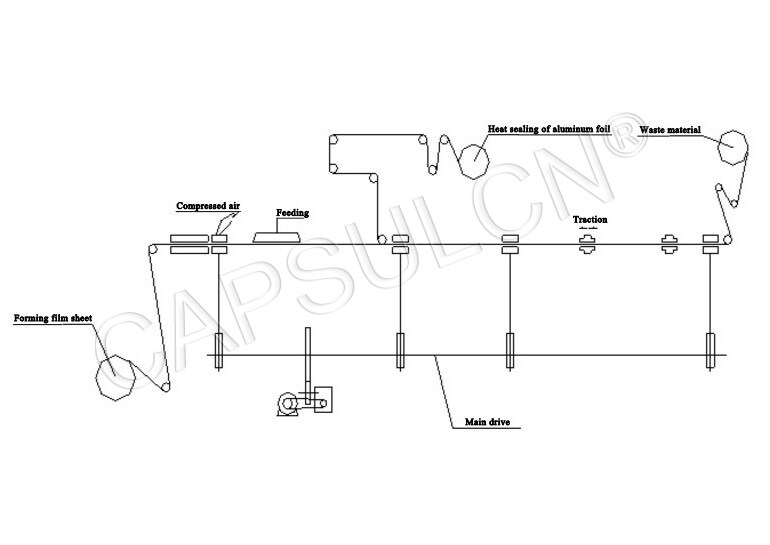

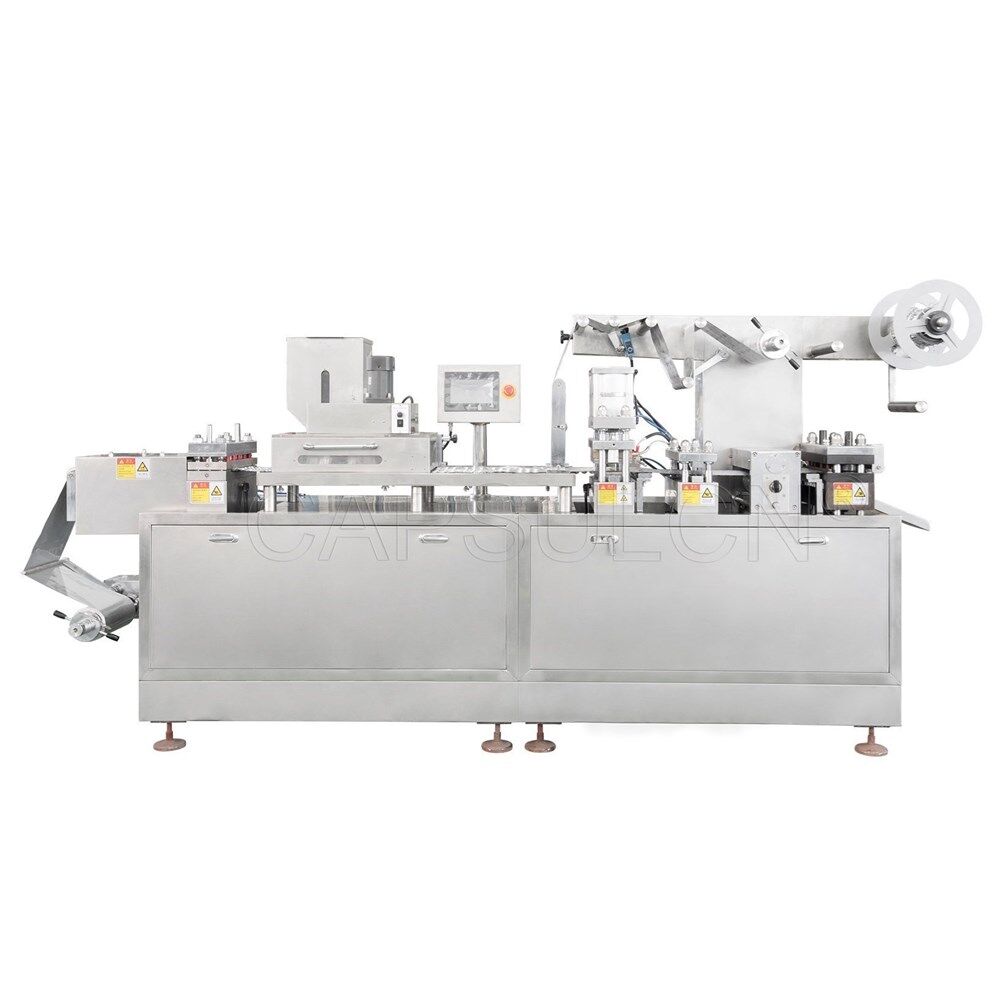

Flat-plate blister packaging machine is a kind of special equipment for PTP/PVC or PTP/PTP compound sealing packaging of drugs (including tablets, capsules and ampoules), food, medical instruments and similar materials. Due to positive pressure forming, flat pressing heat sealing, the finished blister sheets are even and smooth, which makes this machine favored by the whole industry.

Introduction

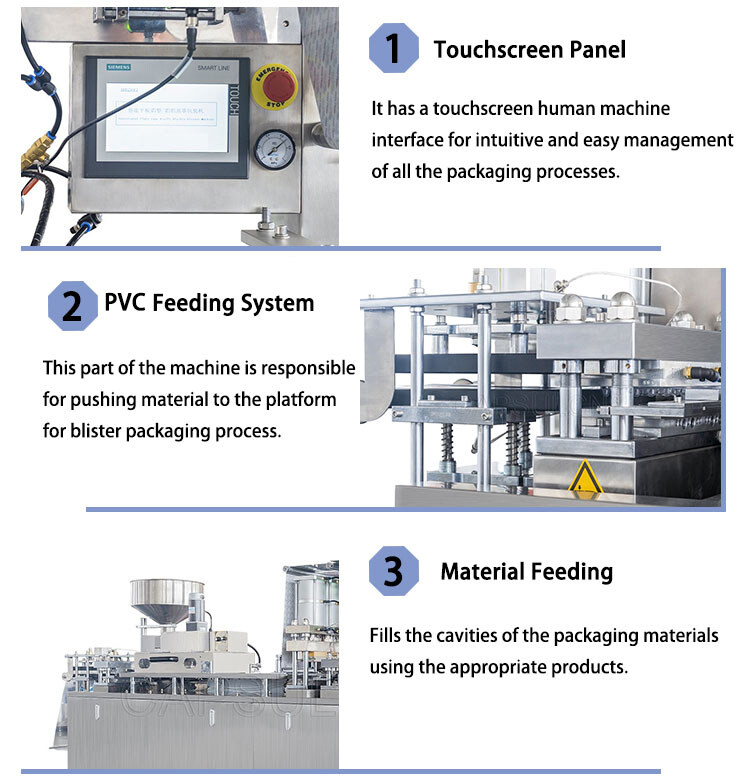

The product is specially designed for hospital dosage room, laboratory institute, health care product, middle-small pharmacy factory, and featured by compact machine body, easy operation, multi-function, stroke adjustable, long durability etc, it is suitable for the Alu-PVC package of medicine, food, electric parts etc. Aided forming Pre‐cutting Inspection and rejecting control systems. Print mark registration Automatic feeder

Main features:

2) The molds are pressed and clamped by the pressing plate, which makes assembly and disassembly very convenient.

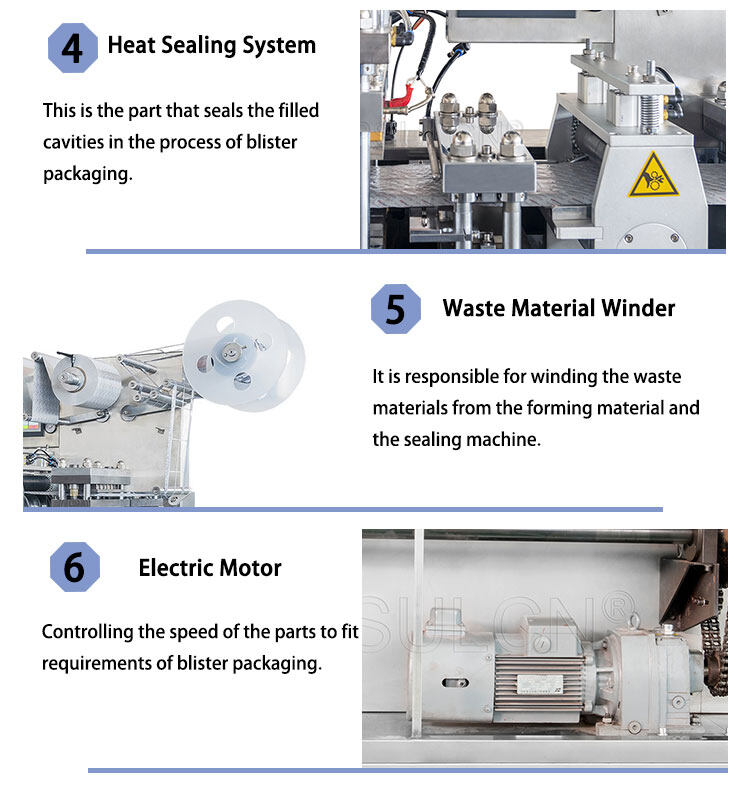

3)The main motor adopts variable frequency speed control: The corresponding blanking times should be set according to the stroke length and the feeding difficulty of the filling materials. (The blanking times can reach 50 times / min).

4) The mechanical arm clamping traction mechanism is adopted to ensure stable operation and accurate synchronization. The stroke length can be adjusted in the range of 30~120mm, which means that the plate size can be designed at will within this range. Because of aligning and heating by contact, the heating power and temperature are reduced, the energy is saved and the stability of plastic sheet is increased.

5)The forming heating plate closes and opens automatically. The start-up time can be delayed after the heating plate is put down, so no more than one sheet of materials will be wasted.

6)It is equipped with cylinder and chequered plate at the heat seal station. When the machine is stopped, the cylinder will automatically raise the chequered plate, which helps avoid the deformation of blisters caused by thermal radiation and also facilitates the cleaning of checkered plate. At the same time, it plays a buffer role in overpressure, which contributes to prolonging the service life of the machine.

7)The upper and lower chequered stripes with netted dots cooperate for heat sealing. As there is equal stress on both sides, the sheets are smoother and the sealing performance is improved.

8) If PVC runs out or breaks off, the alarm rings automatically and the machine shuts down immediately. Besides, the machine is equipped with emergency stop device, which improves the safety of operators during the process of debugging and replacing molds.

9)The feeding hopper and all the other parts in contact with materials are made of stainless steel and non-toxic materials, meeting the requirements of GMP.

Specifications

| Model | DPP-250 |

|---|---|

| Cutting frequency | 10-50 times/min |

| Capacity | 9600strip/h |

| Max shaping areas and depth | Alu-Alu: 240×150×18mm Alu-Pvc: 240×150×27mm (Special model can be 47mm) |

| Travel Range | 40-160mm (Can be lengthened to 180mm as user's requirements) |

| Standard Plate | 80×57mm (Can be manufactured as user's requirements) |

| Air pressure | 0.4-0.6Mpa |

| Power supply | 380V/220V 50Hz 6.2Kw |

| Main motor power | 1.5kw |

| PVC hard pieces | 0.15-0.5*260mm |

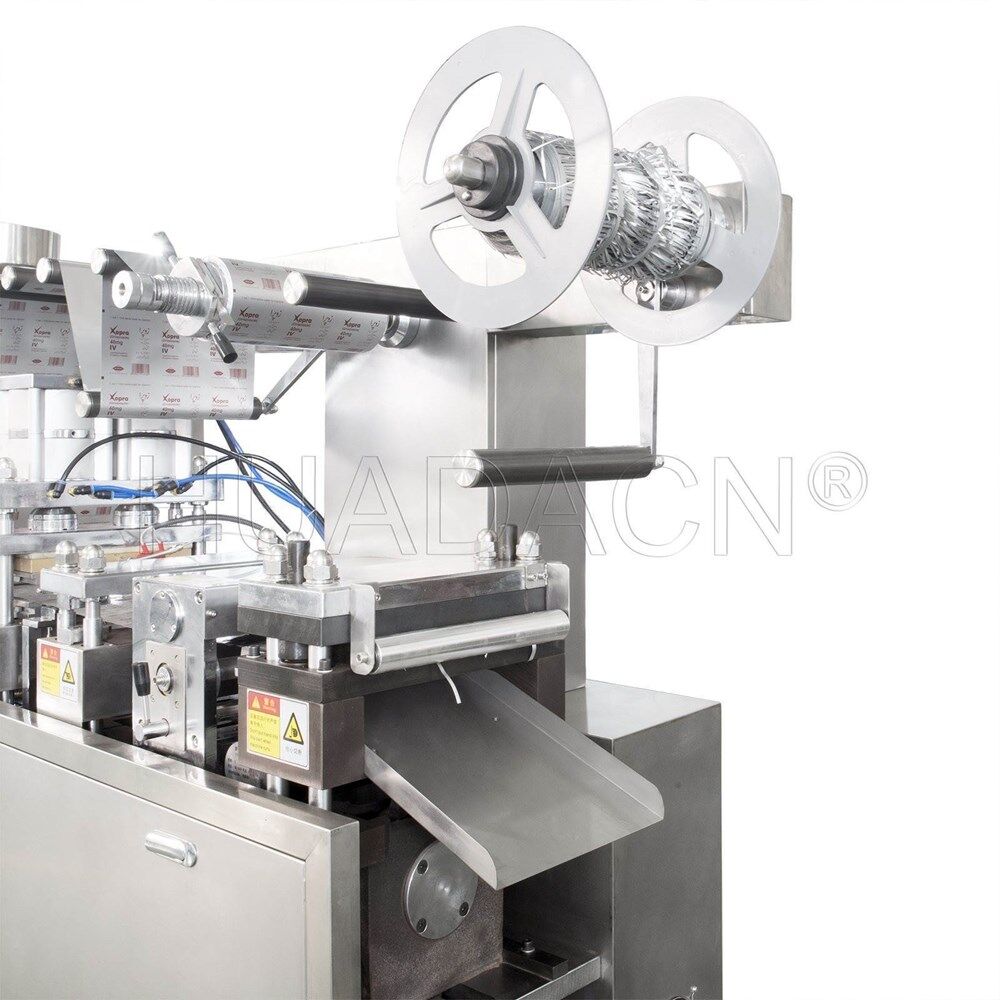

| PTP aluminum foil | 0.02-0.035*260mm |

| Dialysis paper | 50-100g*260mm |

| Mould cooling | tap water or back water |

| Machine dimensions | 3000×730×1600mm |

| Net weight | 1600kg |

(Don't Worry! We have several Models. We can recommend you according to your requirement. Just Tell Us: Capacity, packing machine and Capsule Size.)

Remarks

- Best option for small batches, pharmaceutical R&D and pilot plants.

- It allows forming thermoplastic and cold forming materials (Alu-Alu).

- It stands out for its simple operation, high reliability and compact design. Its main structure is made of stainless steel.

- Automation by PLC and operation through touch screen control panel.

- It has pneumatic drives, which lend it high robustness and low maintenance.

- It is suggested for R&D departments, considering that its easy operation and maintenance makes it user-friendly to personnel that are not familiar with the use of blister machines.

review(s)

Very good

The machinery has been used for 6 years, and there are no major problems, very good.

From: ruixue | Date: 3/2/2021 12:24 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Blister Packing Machine DPP-250

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche