Mixing process in the pharmaceutical industry

Drugs are often made from various constituents. These constituents often pass through multiple processes to give the final product. Blending/mixing is one of these processes used in pharmaceuticals. Blending is an important process in drug production. The blending process in pharmaceuticals is the process of physically combining two substances to give a mixture which would then be passed on to the next stage of drug development. This article would discuss the blending process, its principles, and some of the equipment used.

Dry blending process

As the name implies, the dry blending process involves the combination of substances in the dry solid form. These substances are usually powders, but may also be in form of granules. They are the active pharmaceutical ingredient and an excipient, which is basically a non-active ingredient. These excipients serve different purposes like serving as carriers for the active ingredient. Thru also increase the size of the final drug, maintains the viability of the API, and in certain cases, enhances the absorption of the drug. The main equipment used in the blending process is specialised pharmaceutical blenders. This blending/mixing process in pharmaceutical industry usually involves loading the materials to be blended into the blender, and then turning it on and waiting for minutes to complete the blending process.

Relevance of blending in the pharmaceutical industry

1) Helps to ensure equal distribution of constituents

The process of blending does not just help in reducing the size of constituents. It also helps to mix these constituents. The motion inside the compartment is uniform, and this helps to ensure that the constituents are distributed equally. Equal distribution of the composite parts ensures that the mixture has a similar concentration of API all around. This ensures that the dosage of API is kept constant.

2) It helps to make the process of compaction efficient

One of the steps of drug production that follows blending, is compaction. Not only does blending precede compaction, but it also plays a key role in the efficiency of the process. A high level of homogeneity following blending would help to enhance the process of compaction. Conversely, the presence of a high level of discrepancies in the properties of the constituents would negatively affect compaction.

3) Prevents de-mixing of the constituents

The aim of proper blending isn't restricted to just ensuring accurate dosing and aiding compaction. Proper blending is also needed to maintain the mixture between the API and the excipient. When two different materials of varying particle sizes are mixed, they wouldn't stay that way for long. Over time, segregation occurs and de-mixing takes place. Proper blending would ensure both materials are of similar particle sizes. This would help maintain the mixture over time and prevent de-mixing.

4) It provides aesthetic value

When done properly, the blending process in pharmaceutical industry also contributes to the visual properties of a drug. Proper blending would give a homogeneous mixture. By extension, this would give a uniform appearance, thus contributing to an overall pleasing appearance.

Quality control measures in the blending

To maintain the quality of the blending process, certain factors must be kept in mind. Some of them are listed below:

1) Regulation of temperature and humidity:

Regulation of the temperature and humidity levels is an important step in ensuring quality control in pharmaceuticals. High temperature and humidity can affect the process and outcome of blending in various ways. They may increase the stickiness of particles and impede their easy flow. This in turn reduces the efficiency of the blending process. Additionally, increased humidity may also encourage the growth of microorganisms which may contaminate the drugs being produced.

2) Cleanliness:

Like every other procedure involved in the production of food and drugs, the practice of great hygiene is a major part of maintaining quality. Routine cleaning of your blender is the way to go. In addition, other materials used in the blending process should also be kept clean during and after the procedure. This includes the clothing worn and the surfaces in the room where blending takes place. Keeping the process as clean as possible would prevent the transmission of diseases among all staff in the drug-making process, and would also prevent contamination of the drugs being made.

3) Use of the right equipment:

Making use of the right equipment is another way to ensure the quality of the dry mix process. It is important to know the appropriate blender to use depending on the size, nature and volume of the material you wish to blend. Furthermore, knowing the operation of this equipment would also help to ensure a high quality is maintained.

4) The right application of the blender:

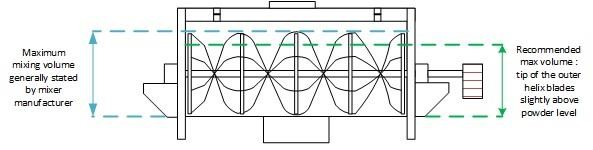

In the pharmaceutical mixing process, choosing the right blender alone wouldn't cut it. The right use of a blender would go a long way to ensure the quality of the process. Take, for example, a ribbon blender that works optimally when it's filled to about 50% of its capacity. Filling that blender to 80% of its capacity is sure to compromise quality. Hence, the need to adhere to the instructions associated with each blender.

Types of blenders used in the blending process in pharmaceuticals

The main equipment used for dry mixing in pharmaceutical industry is powder mixing machine. Some of these blenders used in the dry mix process are the v-type blender, the double Cone blender, the ribbon blender, the octagonal blender, and the bin blender.

Here is some information on these types of blenders.

1) V-cone blender:

V-cone blender is made of two identical metallic cylindrical tubes fused at an angle of about 80 degrees to each other. Each tube has an opening through which the materials can be loaded into the mixing compartment. Blending is achieved by steady rotation around a fixed horizontal axis. An important feature of the v-cone blender is the absence of choppers within the blending compartment. This - combined with the steady rotation - means that each of the materials retains its individual properties to a large extent even after mixing. This makes the v-cone blender an excellent choice for blending fragile materials. Hence, it is a valuable tool in the pharmaceutical powder blending process.

2) Ribbon blender:

Ribbon blenders can be used to blend both dry and wet materials. Within its blending compartment are two groups of blades - the outer and inner blades. The synergistic action of these blades provides the blending action. They don't only help in mixing the materials, they also provide a shearing force on them. This force helps to turn the materials into more fine particles. The combined mixing and shearing action helps to produce a homogenous and uniform blend. In addition to these, it also comes with other functions such as spraying, heating and cooling.

3) Double Cone mixer:

Double cone mixer is used majorly for the mixing of powder substances. Its design consists of two asymmetrical cone-shaped barrels. In addition, there are usually metallic blades within the mixing compartment to facilitate a breakdown of the materials. This helps to give a final product with fine particle size and high homogeneity. The double-cone blender is unique, in that it can be used for blending and mixing materials with different specific gravities. The process of blending generally takes between a quarter to half an hour and is generally noiseless.

4) Octagonal blender:

It is a great option for the dry blending of powdered materials. In addition to blending materials in powdered form, it is also suitable for blending materials in granule form. It can be filled up to about 2/3 of its capacity, making it suitable for blending greater quantities of materials compared to some other blenders. Despite being able to blend great volumes of materials, the equipment takes up less space than many other types.

5) Bin-blender:

As the name implies, the blending container is shaped like a bin. This container is attached on both ends to a frame and has a loading valve through which the materials to be blended are loaded into the blender. The mixing of the constituent particles is achieved through gravity and diffusion of these particles. Eventually, after several minutes of blending, you get a homogenous mix which can be expelled via an unloading valve. Unlike the ribbon blender, there are no blades within the blending compartment. This feature, combined with the slow rotation, makes the bin blender an ideal option for friable materials. For maximal blending effect, is best to fill up to only about 50-60% of its capacity.

Factors to consider before buying a pharmaceutical blender

When trying to choose a pharmaceutical blender, there are various factors to consider.

1) The type of material to be blended

The choice of blender largely depends on the properties of the material you intend to blend. Some of these properties are the size, shape, and density of the substance to be blended. For example, many of the blenders are suitable for blending substances in their powdered form but not granules. However, the octagonal blender is suitable for both. Knowledge of the features of the blenders would help you make an informed choice.

2) The particle size required

The end product following blending often varies. This depends not only on the time taken to blend but also on the type of blender. Various blenders give different levels of blending. Take, for example, a ribbon blender. It comes with two groups of blades inside the blending compartment. This helps to break down particles even further during blending. Now, this process may be suitable when you desire very fine and small-sized powders. However, it may not be appropriate when you desire larger particles.

3) The size of the mixing compartment

Blenders come in different sizes, and naturally bigger blenders would have bigger blending compartments. In addition, the maximum capacity of blenders varies, depending on the type of blender. For example, certain blenders would have to be only 50% full for optimum blending. However, the proportion needed to be filled for certain other benders to perform optimal blending could be as much as 60%. Hence, if you wish to blend larger quantities of materials at once, it is more appropriate to go for a blender that would take larger quantities.

4) The cost factor

Of course, every project that would require the purchase of a pharmaceutical blender is likely to be a long-term one. Hence, there are various cost factors to be considered before buying a blender. The price to purchase the blending is the first, as the cost of blenders varies, depending on the type and model. The cost of maintenance of the blenders is also another factor that should be put into consideration. Certain blenders are a lot easier to maintain than others.

Knowing these features would help you make decisions on blenders that would suit your budget.

Final Words

The importance of blenders and the pharmaceutical blending process cannot be overstated. It is important to ensure adequate blending of APIs with excipients, for various reasons. Not only does it help to ensure accurate dosing. It also helps to facilitate the subsequent stages of drug production.

At IPharMachine, we provide a wide variety of pharmaceutical blenders to suit your needs. We also provide other pharmaceutical equipment like capsule filling machines, tablet pressing machines, blister packing machines, among others. All these and many more are available and at affordable prices. So why don't you reach out to us and let us cater for your pharmaceutical machine needs?

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche