Introduction

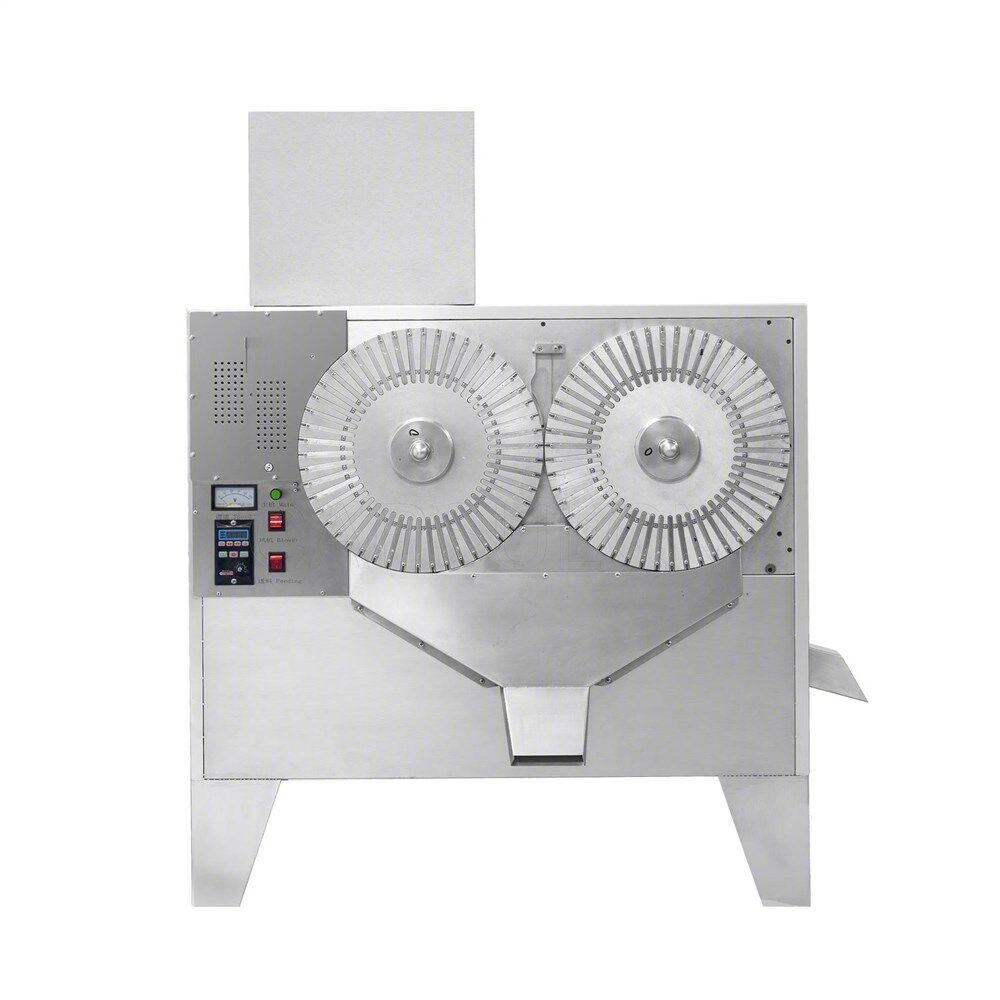

This is the world first machine designed to separate empty hard capsules. It can separate the caps from the bodies.

It is ergonomically designed; suitable for capsule sizes from size 000# to size 2# with applicable change parts; easy to clean and maintain; user-friendly and meet the cGMP Standard in the industry. It is an excellent machine to own by any capsule manufacturing plants.

Specifications

| Production capacity | 30,000-90,000pcs/hour |

|---|---|

| Precision | More than 99% |

| Applicable size | Size 000# or Size 00# or Size 0# 1# 2# (parts interchangable) |

| Air pressure | 14.7kPa |

| Air comsuption | 75m3/h |

| Power supply | 110V 60Hz / 220V 50Hz Single Phase |

| Power | 1KW |

| Overall dimension | 1100*500*1300mm |

| Weight | 145KG |

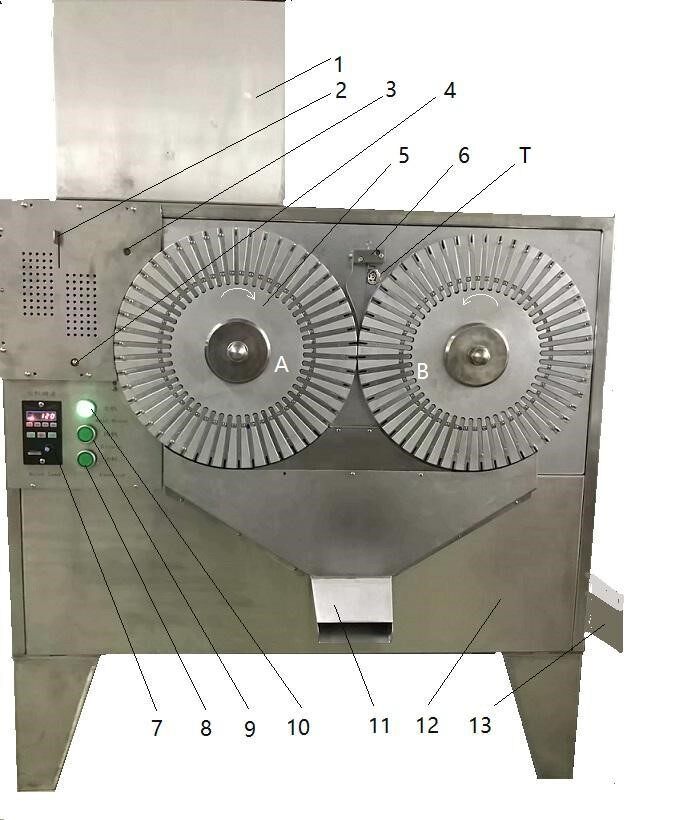

Structure

| 1.Hopper | 2.Feed gate | 3.Limit brush wheel |

| 4.Vibrating brush wheel | 5.Mold plate | 6.Capsule positioning rod combination |

| 7.Speed governor | 8.Feeding switch | 9.Fan switch |

| 10.Host switch | 11.Capsule body outlet | 12.Rack |

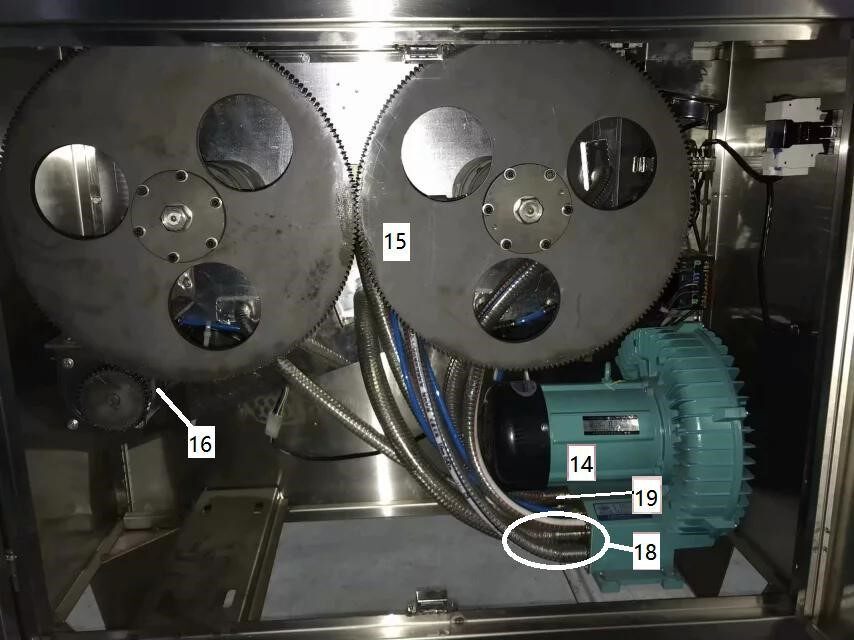

| 13.Capsule cap outlet | 14.Fan | 15.Gear |

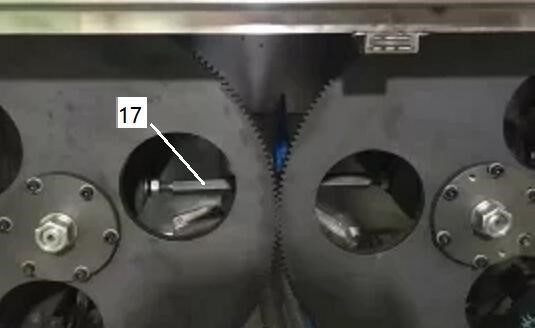

| 16.Host | 17.Gear meshing adjustment lever | 18.Outlet tube |

| 19.Suction tube | 20.Angle adjustment plate (factory has been adjusted, do not mess) | |

Safety precautions (please be sure to follow)

1. Please check the voltage indicated by the machine.

2. Disinfect the machine with medical alcohol before the machine is operated. After using the machine, be sure to turn off the power switch and unplug the power cord.

3. Please use a single-phase grounded socket and ensure reliable grounding.

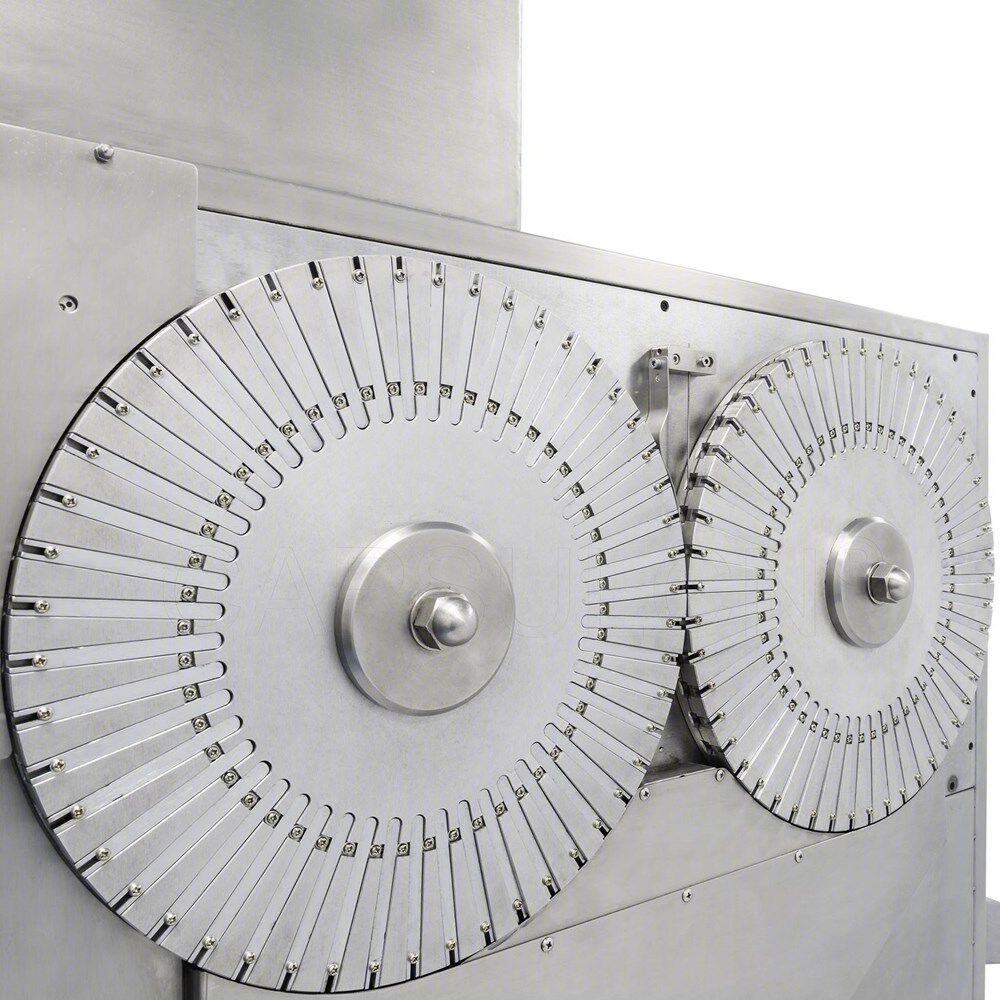

4. The mold plate cannot swap position.

5. Do not touch the mold plate by hand when the machine is running! Do not open the rear door of the machine to contact the running gear!

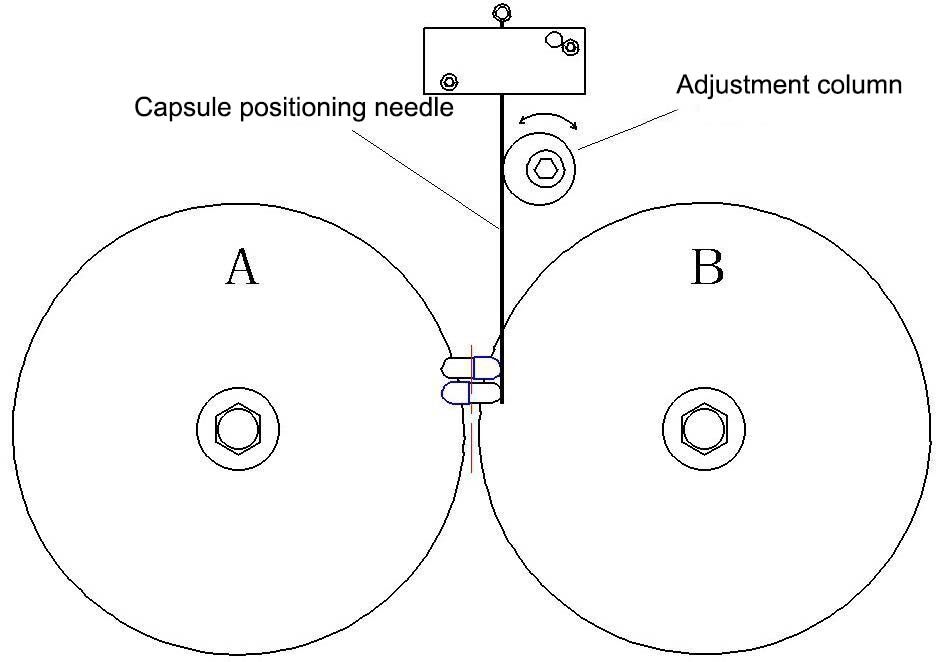

6. A gear rotates clockwise, B gear rotates counterclockwise, and cannot be reversed.

7. If the machine is found to be working abnormally, please stop using the machine immediately, ask the professional maintenance personnel to check the repair, or contact the supplier.

Common problem

If the separation capsule does not work well, please check:

Check if the swing arm activity on the die plate is flexible

Solution: Adjust the position of the swing arm and module

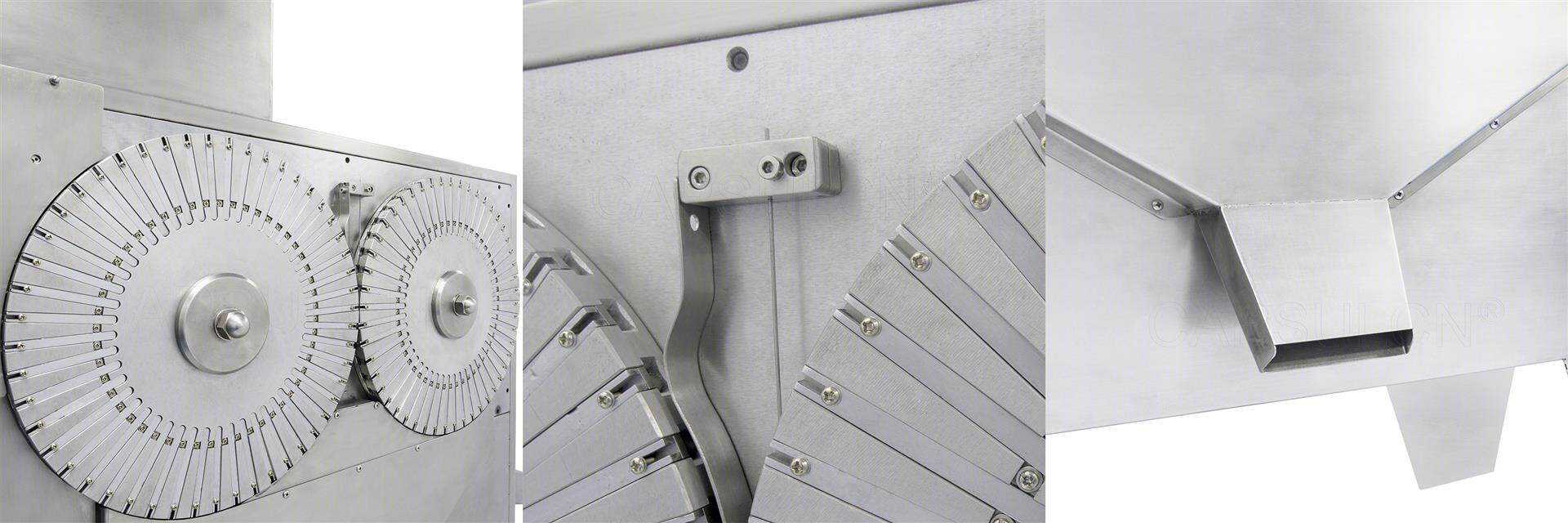

Capsule positioning steel needle position is wrong

Solution: Adjust the position of the swing arm and module

Displacement of two mold plates

Solution: Pay attention to the installation of the mold plate. The module swing arm on the AB mold plate should be on the same horizontal line as much as possible.

Mold plate channel blockage

Solution: Rotate the die in the direction of rotation, check each die channel, and clear the blocked capsule

Module model is wrong

Solution: Replace the required module

Machine speed is too fast

Solution: choose the appropriate speed

Capsule deformation

Solution: Replace the capsule

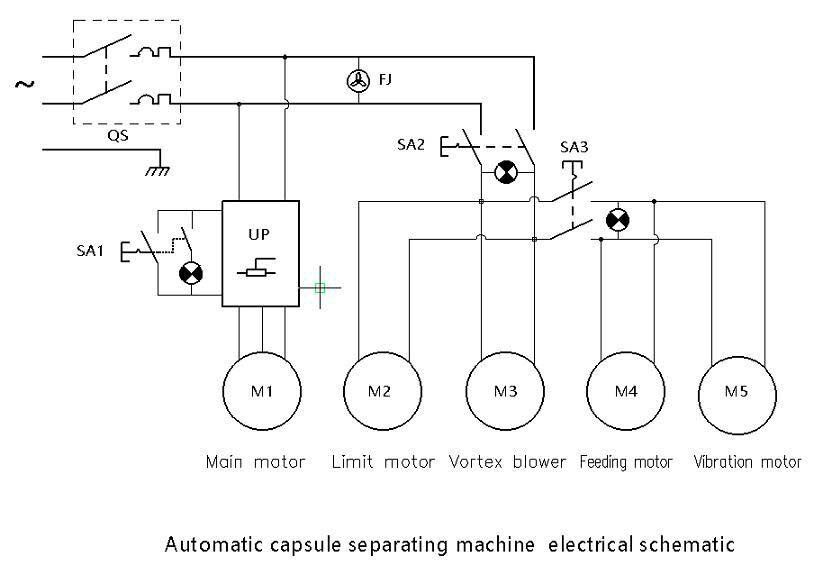

Electrical schematic

| QS Air circuit breaker | UP Intelligent governor | SA power switch button |

| FJ Axial Fan | M1 Main motor | M2 Limit electric motor |

| M3 Vortex pump | M4 Feed motor | M5 Vibration motor |

review(s)

good

Use this machine to separate the capsules. Most of the time, the cap and body are separated and sometimes mixed together, but they are not the same size and can be screened directly with a capsule.

From: Guest | Date: 9/20/2019 2:10 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche