The Ultimate Guide to Buying a Film Coating Machine

Are you new to tablet manufacturing? Aside from tablet compression, do you know that tablet coating machine is also a critical step in a tablet production run?

Tablet coating, so to speak, is one of the oldest pharmaceutical processes still in existence. As technology advances, the tablet coating process has been further developed. There are three types of tablet coating: film coating, sugar coating, and enteric coating, of which film coating is the most popular process currently used.

To perform such a process, you need a film coating machine. So, how to choose the right film coating equipment for your business? How do you get the most out of your film coating machine? If you intend to get one, this guide will help you make an informed decision. Let's get started!

First, what is a film coating machine?

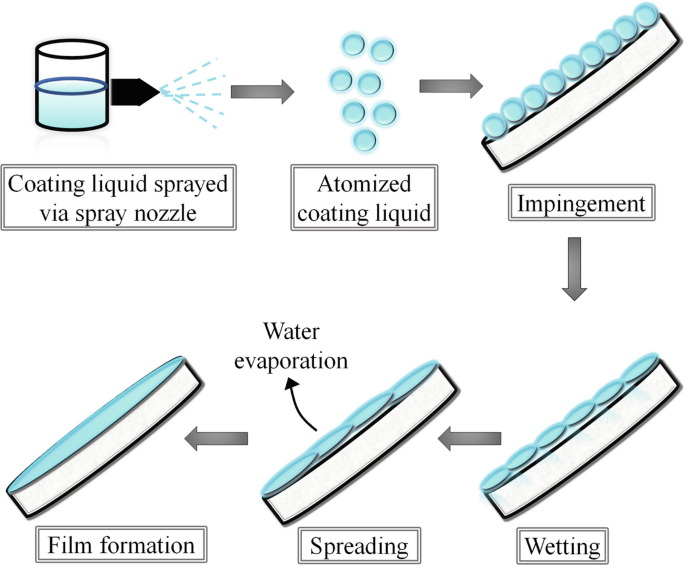

A film coating machine is a type of tablet coating machine that applies a thin polymer film to the surface of the tablets employing a spray method. Using such a machine can greatly speed up manufacturing, as tablets are small and susceptible to breakage if handled incorrectly.

(Image credit: Optimization of Pharmaceutical Processes)

What are the types of film coating equipment and how do they work?

Based on tablet ingredients, the properties of coating solutions, the maximum output and speed level, and other specific production needs, there are mainly 3 types of film coating machines out there.

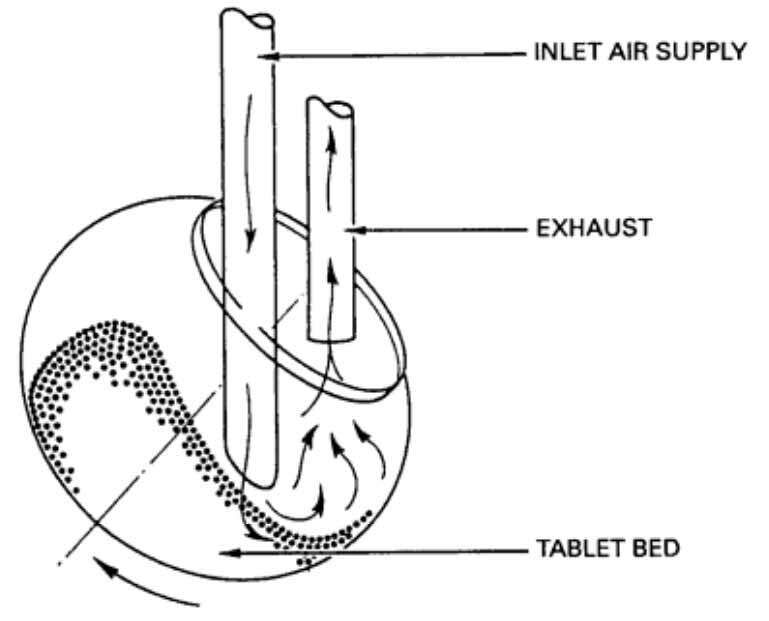

1. Standard coating pan

This machine performs the coating process in a circular metal pan. The coating pan mounted tilted on a stand is driven by an electric motor.

Working principle: After loading a batch of tablets, the metal pan starts to rotate. The motion allows the tablets to tumble and get sprayed with the premixed coating solution. The air-atomized spray system enables the coating solution to be evenly distributed onto the tablets. At the same time, heated air is drawn into the tablet bed to dry the solution. After that, the heated air is exhausted by the duct.

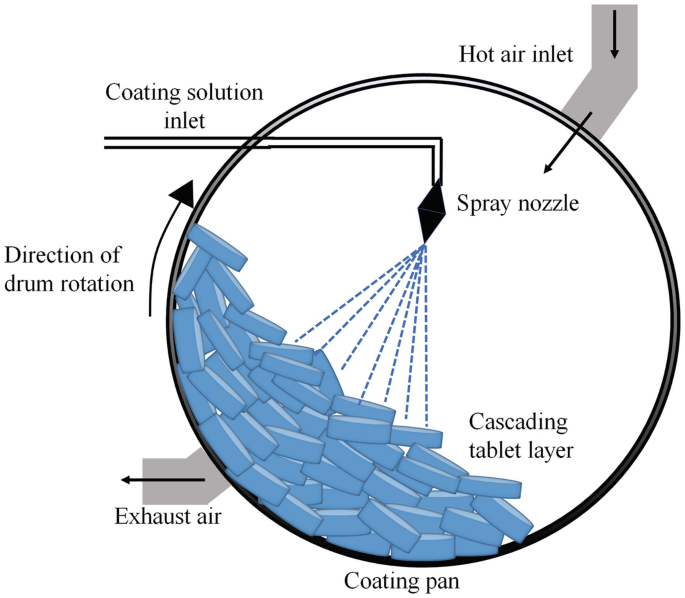

2. Perforated pan or drum

Perforated pans are the most widely used tablet coating machines in modern pharmaceutical and nutraceutical industries. The film coating equipment consists of a partially or fully perforated drum that rotates in an enclosed housing.

Working principle: As the tablets are tumbling in the drum, the manifold spray guns inside the drum evenly distribute the coating solution to the surface of every single tablet. In the meantime, the drying air enters the drum and passes through the tablet bed. Finally, the air exits the machine through the perforations of the drum.

(Image credit: Optimization of Pharmaceutical Processes)

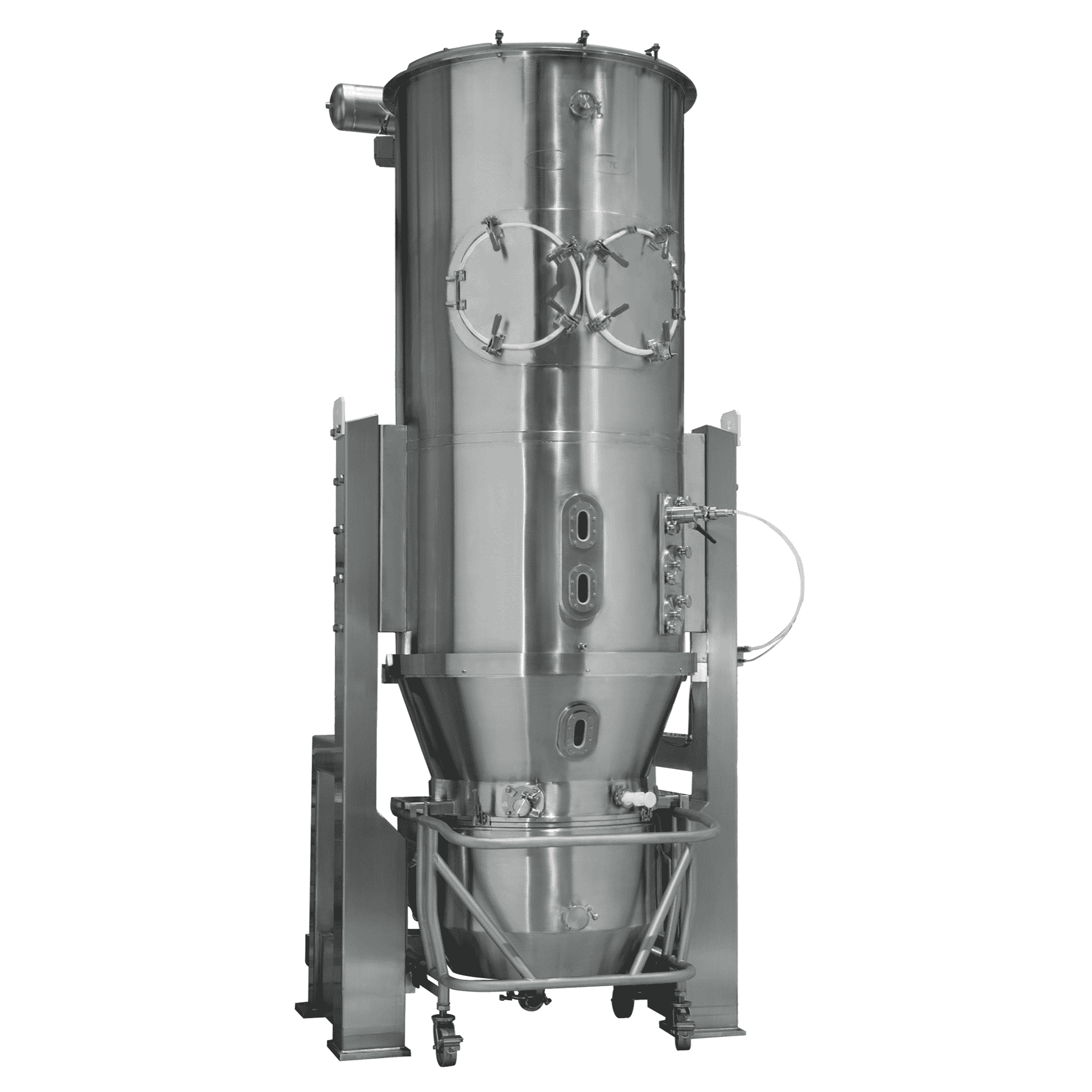

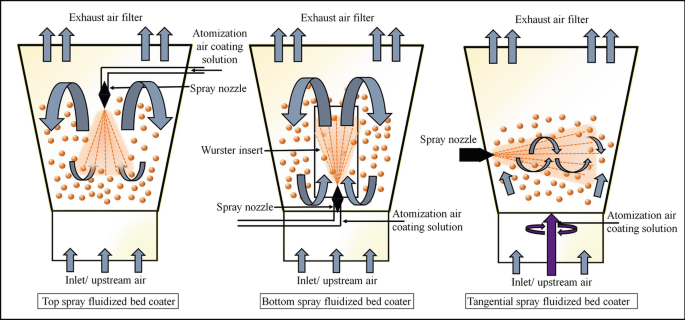

3. Fluidized bed or air suspension system

The fluidized bed application method, also known as the air suspension system, is a highly efficient film coating equipment. It features a vertical cylinder and a high pressure airless system. The atomizer system is capable of producing ultra-fine spray to create perfectly uniform thin films.

Working principle: During the fluidized bed coating process, high pressure air flows upwards from the bottom, enabling the tablets to suspend in the center of the cylinder. At the same time, the coating solution is continuously applied to the tablets using spray nozzles. And then, the tablets fall toward the cylinder walls and slide downward. They reenter the airflow at the bottom of the cylinder to go back up.

(Image credit: Optimization of Pharmaceutical Processes)

Why is the film coating equipment such a big deal?

The film coating on the tablets helps improve their quality and makes them easier to swallow. In the meantime, an appropriate coating substance can keep oxidization at bay when the tablets are exposed to air, moisture, odor, and light, thereby improving your product's shelf life.

The thin polymer film on the tablets is usually colored and shares many of the same qualities as the sugar coating, with the added advantages of being more stable, less bulky, and requiring the least amount of time to apply.

What are the benefits of film-coated tablets?

- To make medications more palatable by masking their tastes or odors;

- The compact, appealing, and smooth design makes swallowing easier for children and the elderly;

- Stable in terms of its chemical, physical, and microbial characteristics;

- Non-toxic and tasteless polymer ingredients increase the medication's bioavailability, dissolving rate, and duration of action;

- Designed to dissolve and expose the tablet core to the desired place in the gastrointestinal system;

- To modify the API's release to get the required tablet performance;

- To serve as a barrier, preventing the tablet from dissolving in the stomach acid;

- To increase the durability of the tablets during packaging and shipping;

- To minimize the potential contamination for the API in the downstream process;

- To reduce dust in the production area.

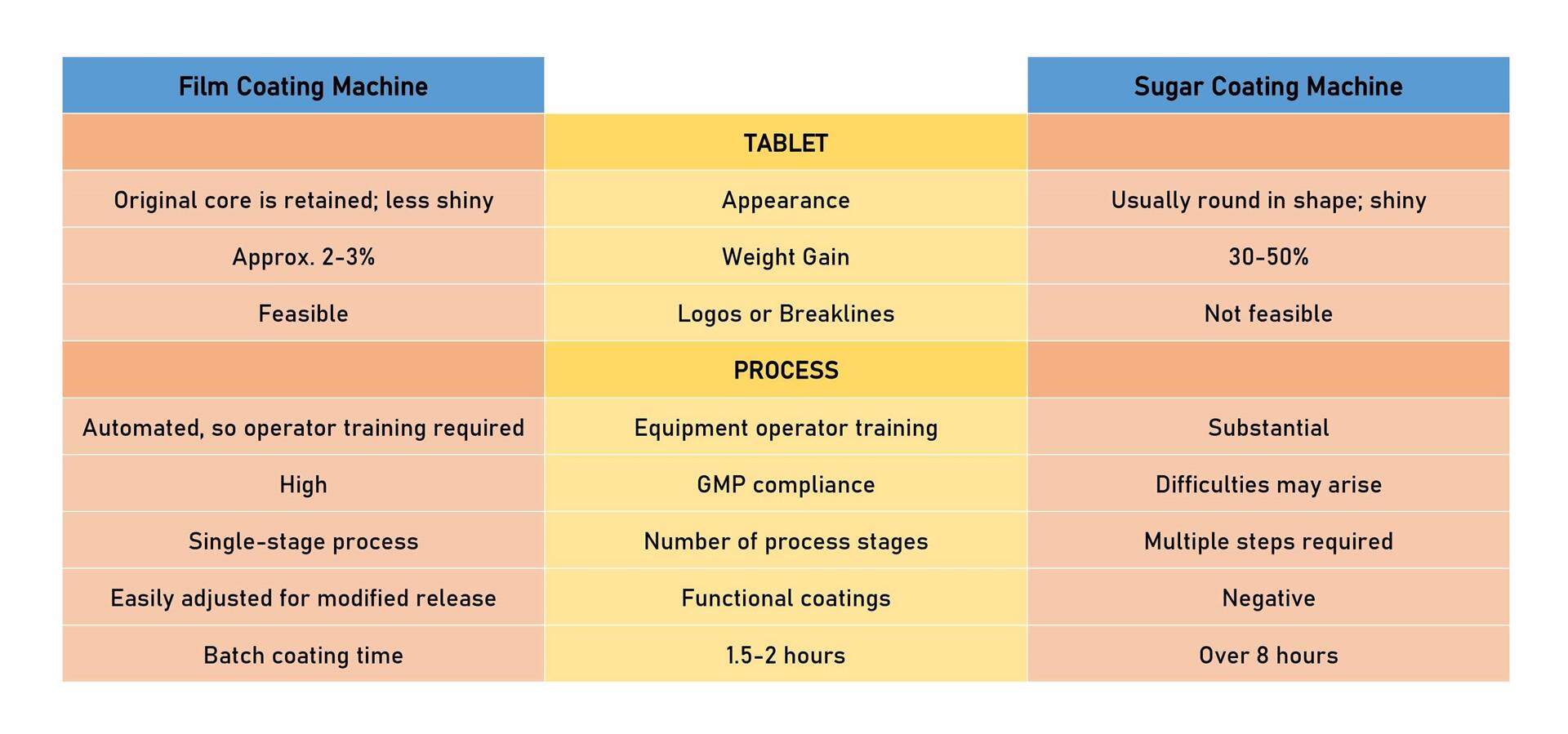

Why is a film coating machine preferred over a sugar coating machine?

Here's a table to explain why you should choose the film coating equipment over the sugar coating type.

As you can see, the film coating equipment allows you to produce higher-quality tablets and makes your manufacturing more flexible.

Future trends of the film coating machine

In the global market, film coating is the most commonly used technology due to its cost-effectiveness. The demands of the pharmaceutical business have led to numerous changes in film coating technology. It is not just restricted to the pharma industry; it is also widely used in the food industry.

To make the entire process less expensive, film machine equipment manufacturers are attempting to reduce the loss during the coating process. The film coating industry has always been looking for a way to advance the technology to meet the needs for higher-quality medications, higher yields, and less waste.

Where to buy a quality film coating machine?

If you have read this far, you'll probably wonder where we can get such a versatile device. At iPharMachine, we offer an array of film coating machines, including standard coating pans and perforated pans.

The BYC series comes in a wide range of conventional coating pans. These robust, adjustable pans are all equipped with the PLC control system for flexible operation and stable performance. They can handle tablets of 3-150kg per cycle, available for different applications from laboratory use to commercial production.

If you're looking for film coating equipment with a perforated pan system, go for our BG-600E. This highly efficient machine features manual and auto modes for more flexible operation. The BG-600E exhibits high anti-interference performance, low failure rate, low maintenance, and good scalability.

In addition to the high-quality products, we also provide you with top-notch customer service. Field service, 24/7 online technical support, and anything else you need to empower your tablet manufacturing is all available at iPharMachine.

Contact us today!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche