Fluid Bed Dryers Explained: Definition, Components & Types

Drying is a crucial step in raw material processing. It ensures the medicine is in the right form for making tablets or capsules. Proper drying also helps to extend the shelf life of the medicine and ensures it works effectively. Currently, fluid bed dryers are commonly used in the market. They are widely used in many industries. If you are interested in buying this drying machine, it is important to have a thorough understanding.

What is a Fluid Bed Dryer?

A fluid bed dryer is used to dry solid particles, including granules and powders. In this machine, hot air is blown through a bed of particles, making them float and mix freely. This looks like a flowing liquid, so it is called "fluidized."

A fluid bed dryer has multiple functions. Besides drying, it can also be used for granulation. During granulation, the powder is also in a suspended state. By spraying a liquid binder, the powder particles stick together to form wet granules. These are then quickly dried by hot air.

Moreover, it can be used for coating. In the fluidized state, the thickness and quality of the coating can be precisely controlled. As the particles float and move constantly, the coating material can be evenly distributed. For specific production needs, you can adjust the equipment settings and operating parameters.

Advantages of Fluid Bed Dryers

In a fluidized state, hot air can evenly contact each particle's surface. So it is able to dry the particles evenly. This reduces the risk of over-drying or under-drying. In addition, in this state, the contact area between the hot air and particles increases, significantly improving heat transfer efficiency. This makes the drying process faster and more energy-efficient.

Applications of Fluidized Bed Dryers

Fluid bed dryers are mainly used in the pharmaceutical industry. They can control the inlet temperature to evaporate the moisture. This allows evenly and slowly reduces the moisture. It helps prevent the drying process from being hindered by too high or too low temperatures. It is also used in the chemical industry to process various chemicals. Common include catalysts, resins, and pigments.

In addition, fluid bed dryers have many uses in the food industry. It can dry various food particles and powders. They include coffee, milk powder, spices, and seasonings. This is mainly to ensure the quality and taste of the food.

6 Key Elements of Fluid Bed Dryers

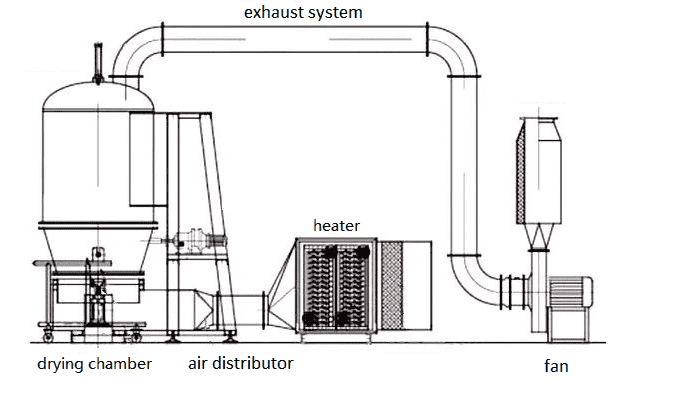

If new to fluidized bed dryers, you must have a basic understanding of the necessary machine parts. The following picture could be for your reference.

Drying Chamber

This is the main part of a fluid bed dryer. The material to be dried is put here. And it provides sufficient space for fluidization and drying.

Air Distributor

It is always located at the bottom of the drying chamber. This part can evenly distribute the incoming hot air across the bed of particles. Then uniform fluidization can be ensured.

Blower or Fan

This part provides the necessary airflow into the drying chamber. The airflow then passes through the air distributor and fluidizes the particles. The blower must provide enough airflow to suspend the particles. It can not be too much, or it may blow the particles out of the drying chamber.

Heater

The heater heats the air to a set temperature, usually in the medium to high range. During the drying process, the heater ensures that the air temperature stays constant. So it allows continuous and effective drying. The heater includes 3 types: electric heating, steam heating, and gas heating.

Exhaust System

It is usually located at the top of the equipment. This is used to remove moisture and exhaust gases from the drying chamber. It prevents them from accumulating in the chamber, ensuring the drying process runs efficiently. This system includes other auxiliary components, such as filters, scrubbers, and fans.

Control System

This system includes some key components, such as the control panel, temperature sensors, pressure sensors, etc. You can set parameters like temperature, airflow speed, and drying time on the panel. The control panel also supports monitoring these parameters in real-time, making it easy to operate and maintain.

Working Principle of Fluid Bed Dryers

Loading the Material

First, put the material to be dried into the drying chamber. Then you should turn on the blower to start the airflow.

Fluidization

Next, the heater warms the air to the desired temperature. The air becomes hotter. The hot air passes through the bed of particles, causing them to lift and suspend, creating a fluidized state. The air distributor ensures that the hot air is evenly distributed across the bed of particles.

Drying

Then hot air transfers heat to the particles, evaporating the moisture. The exhaust system removes the moist air. This process continues until the particles reach the desired dryness. Meanwhile, the fluidized particles keep mixing in the hot air, ensuring even drying.

Cooling and Unloading

The drying process continues until the particles reach the desired moisture content. Then the particles are cooled to discharge. It prevents damage and ensures safe handling. At last, the dried product is collected for further processing, packaging, or use.

3 Common Types of Fluidized Bed Dryers

Fluid bed dryers can be divided into different types based on their design and functions. Each type has its unique features and applications. Here are some main types of fluid bed dryers.

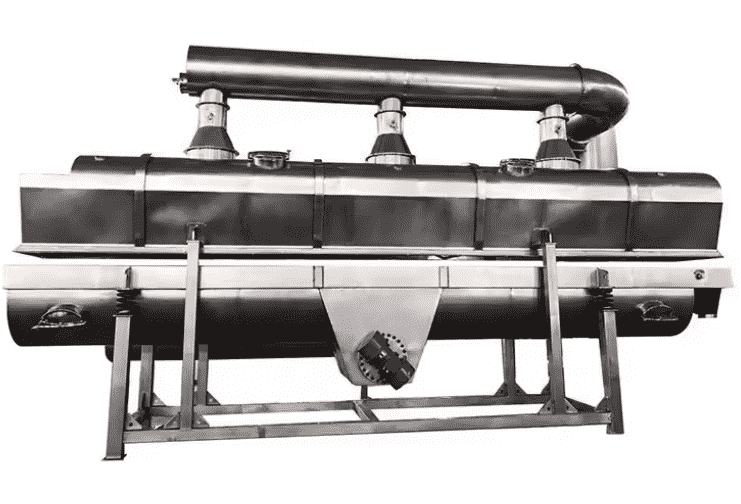

Vibrating Fluid Bed Dryers

This type uses vibration to assist the fluidization process. It can enhance the flow and uniformity of particles, preventing them from clumping together. This dryer is especially suitable for handling larger or heavier particles, such as food granules.

Spray Fluid Bed Dryers

It combines spray drying and fluid bed drying. This machine sprays liquid material into the fluid bed. Then the droplets quickly evaporate in the fluidized state, leaving dry solid particles. You can adjust the spray and airflow parameters to precisely control the particle size and shape. It is suitable for converting liquid materials like suspensions, or slurries into dry powder.

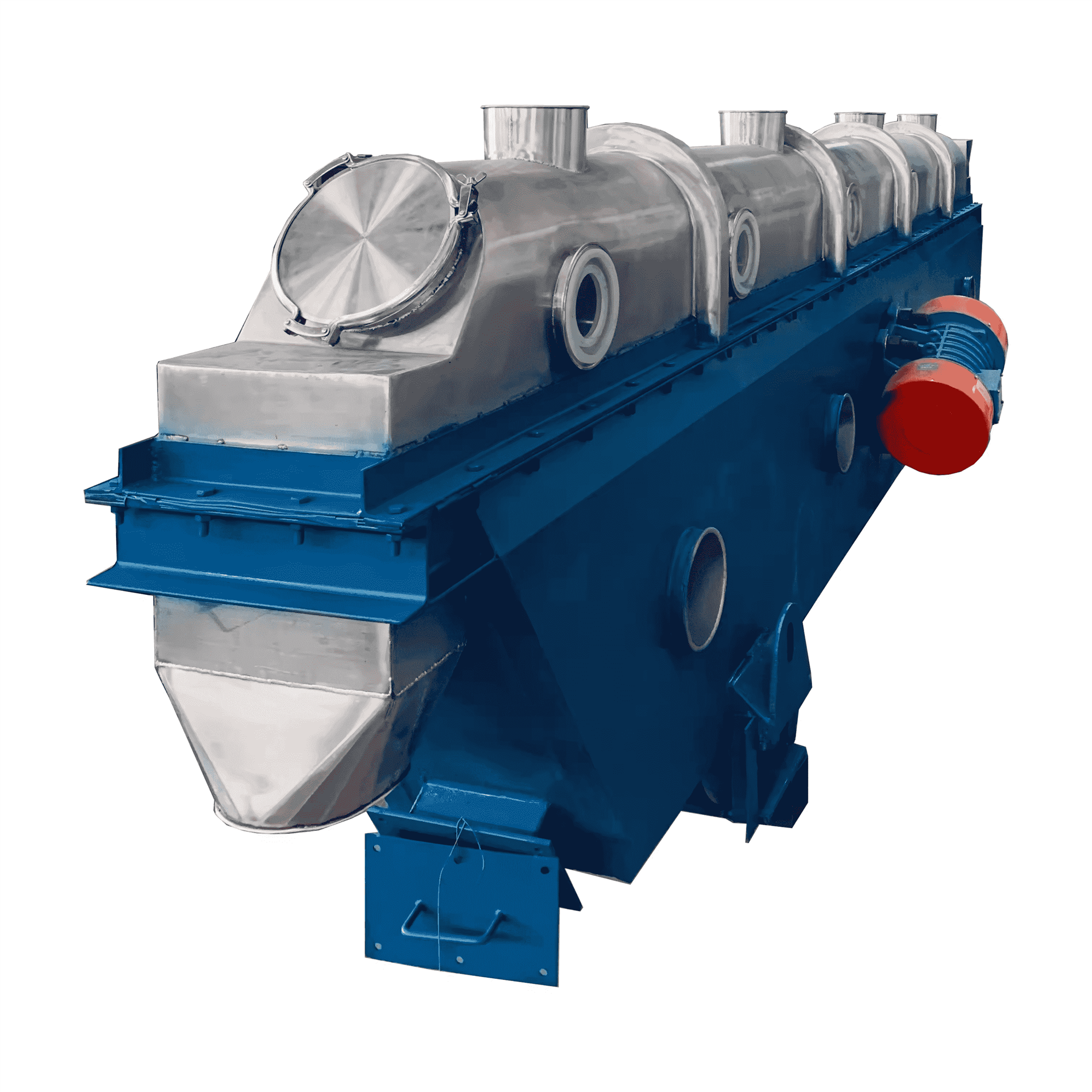

Continuous Fluid Bed Dryers

It features multiple drying chambers in series. Each section can independently control the temperature and airflow to meet drying needs. This provides high flexibility and adaptability. It is suitable for drying various materials in multiple industries. This machine is ideal for large-scale industrial processes that require continuous production.

The End

Fluid bed dryers work as efficient and versatile drying equipment. They have been widely used in the pharmaceutical, food, and chemical industries. If you want a machine that can handle drying, granulating, and coating all in one, this is a good option. If you need separate machines for granulating or coating, you can contact us.

We provide a wide range of pharma equipment with high quality. You can tell us your requirements, and we will choose the most suitable one for your business.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche