Introduction

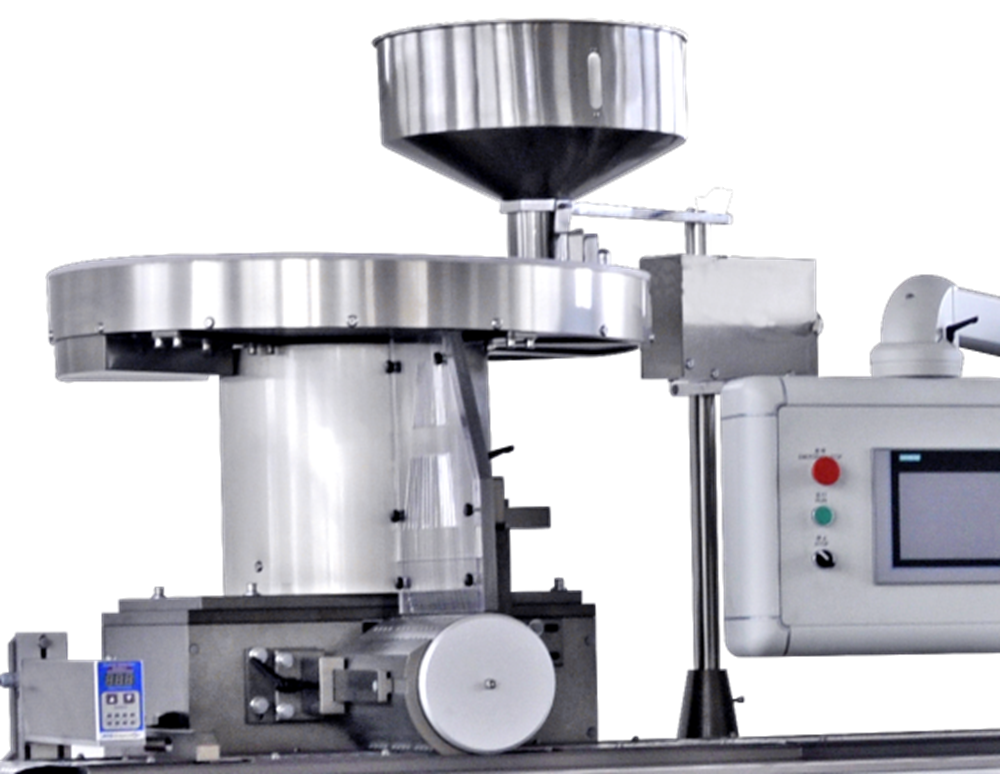

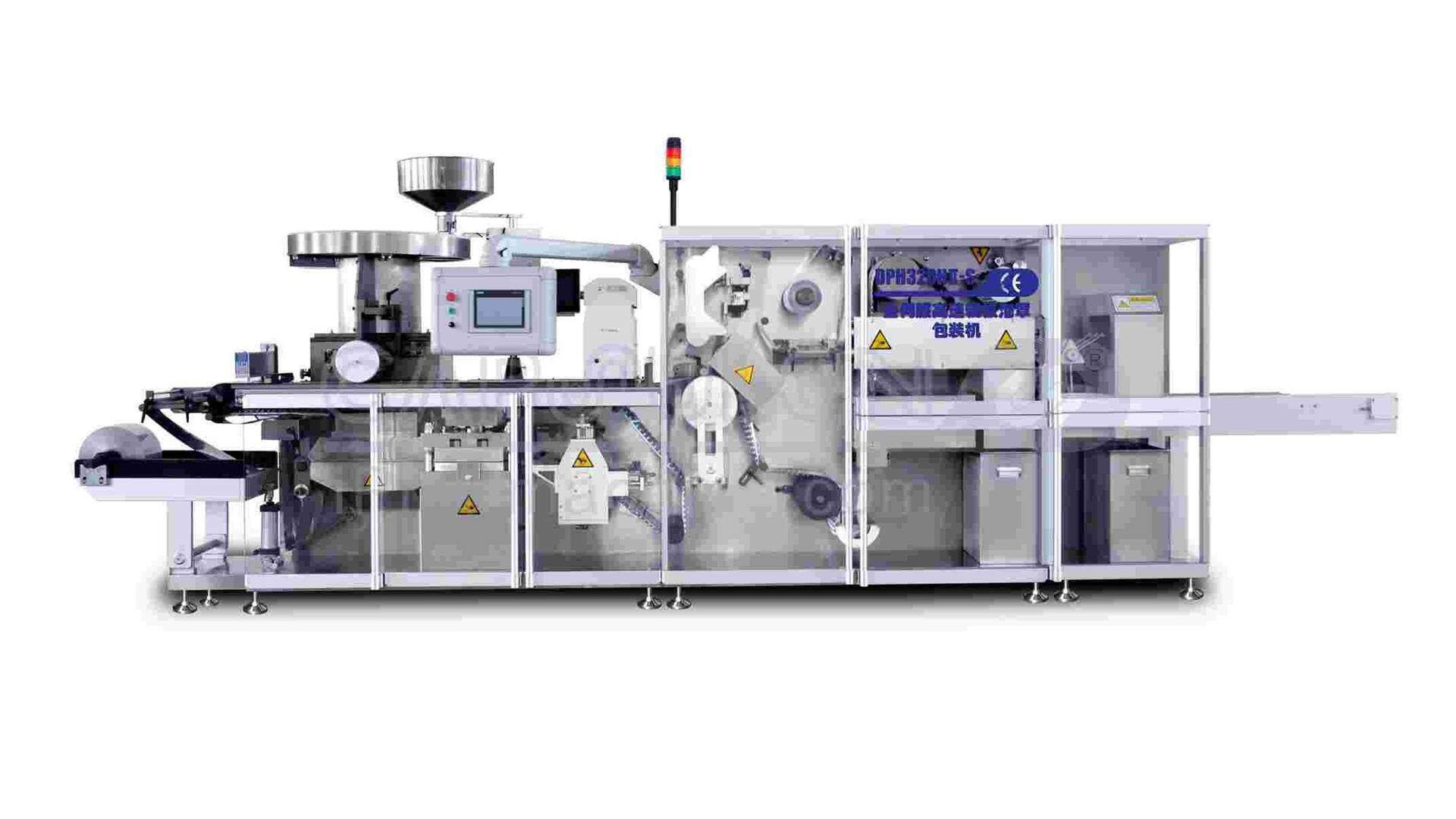

DPH320HⅡ full servo high-speed roller blister packaging machine is a new generation product carefully researched and developed by our company. Its punching times can reach up to 300 times per minute, which is about six times higher than ordinary blister packaging machines. It combines the advantages of flat-plate and drum-type blister packaging machines, and is equipped with a special special-shaped tablet feeder. It has high punching frequency, low energy consumption, accurate and stable movement, convenient mold replacement, high yield, and the ability to misprint Features such as no horizontal waste edge punching greatly improve production efficiency. The whole machine design is more reasonable. It adopts Beckhoff motion control system + Delta servo motor to realize 10-axis full servo fully synchronous operation control, and realizes that one motion control system can complete all motion control, logic and process control of 10 independent workstations. problems, from programming to parameter setting, from testing and debugging to fault diagnosis, improved flexibility, increased cycle rate, shortened reconstruction time and lower maintenance costs, the human-machine interface can be used for industrial control networking, remote monitoring, and data transmission. , parameter modification, collection, storage, printing and three-level password operation protection, integrated automatic control technology with machinery, electricity, light and gas, and innovative design in strict accordance with the requirements of the "GMP" standards of the pharmaceutical industry. The whole machine is combined in separate parts, and the work Bit structure modularization and many other functions.

Features:

- Max capacity 900 blisters/min

- Continuous roller sealing

- Different feeding methods depend on customer needs

- Motion controller and HMI screen

- Eyemark register system

- 10-station full servo full synchronous operation control

- Convenient mold change

- Splice station, convenient material change

- Stagger blister unstriped waste cutting (save waste material)

- Design in line with GMP requirements

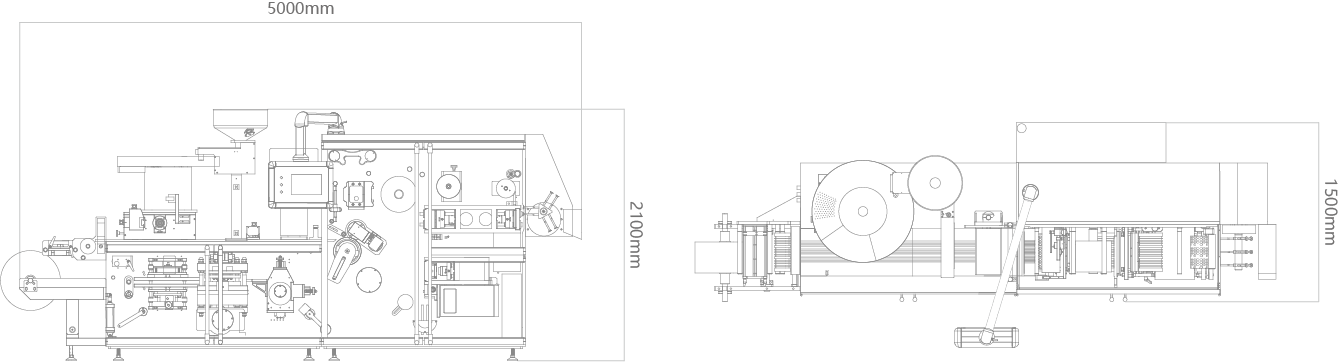

Specifications

| Model | DPH320H | |

|---|---|---|

| Sealing line speed (maximum) | 12m/min | |

| Blanking speed | 60-300time/min | |

| Optional range of feed stroke | 100-280mm | |

| Maximum molding area | 320×280mm | |

| Maximum forming depth | Aluminum | 9mm |

| Aluminum plastic | 12mm | |

| Motor Power | 3KW | |

| Total power of power supply | 29.5KW | |

| Power supply three-phase five-wire | 380/50 V/Hz | |

| Cooling water | nominal volumetric flow rate | ≥20L/min |

| water pipe pressure | 0.1~0.15Mpa | |

| Air pump | nominal solvent flow | ≥0.6m³/min |

| Rated scheduling pressure | 0.5~0.7Mpa | |

| Packaging material | tap water or back water | 0.25×320 mm |

| heat seal aluminum foil | 0.02×320mm | |

| Formed aluminum foil | 0.15×320 mm | |

| Dimensions | 5000×1500×2100 mm | |

| weight | 6000kg | |

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

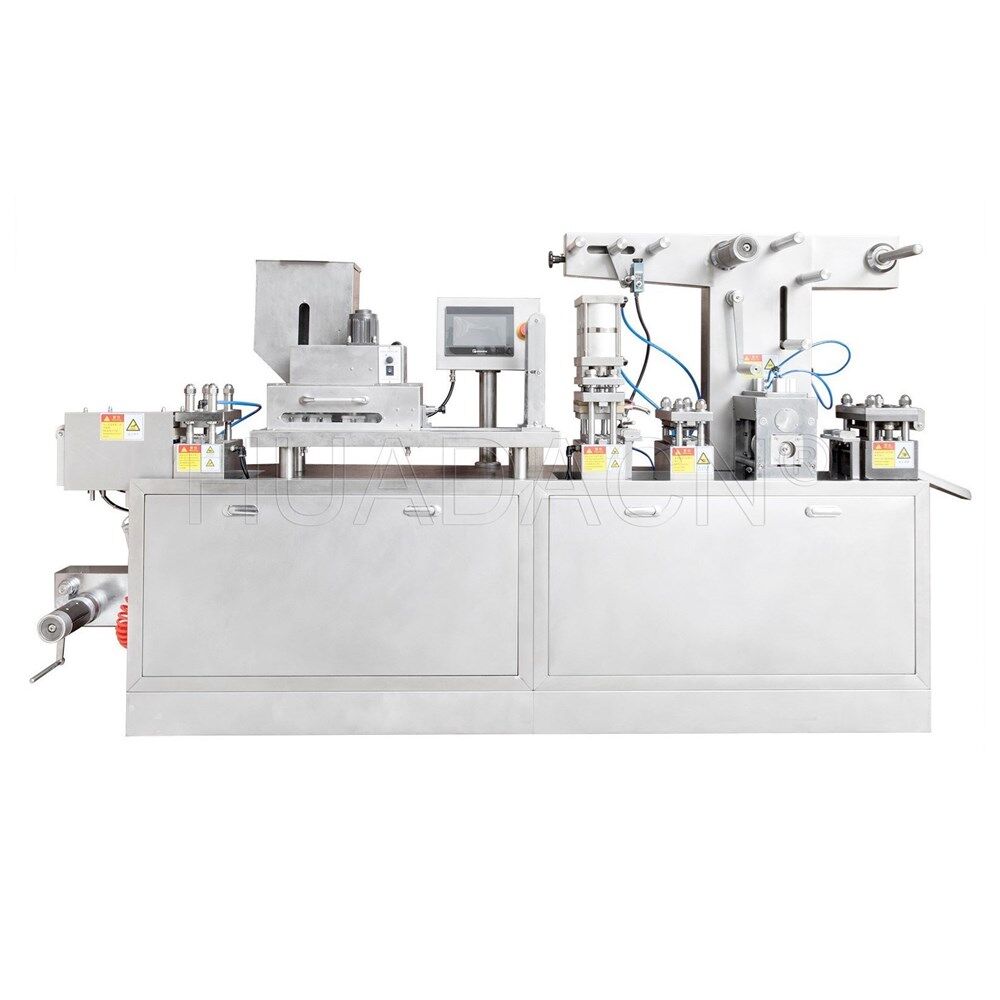

Blister Packing Machine BM-Ⅳ

Blister Packing Machine DPP-160

Blister Packing Machine DPP-88

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche