6 Questions to Answer Before Purchasing a Gummy Bear Machine

As a kind of candy, gummy bears have long been widely loved by people around the world. But today, people are pursuing healthier diets and lifestyles. So, gummy bears are facing new opportunities and challenges. Gummy bears are more than just snacks, they have turned into an attractive health product.

Some active nutrients such as vitamins, calcium and collagen can be added to gummy candies. Pharmaceutical and nutraceutical industries are increasingly using gummies as an alternative to pills and capsules. As a result, there is a growing demand for gummy production machines in these fields.

So, I guess you are looking for a gummy making machine that can perfectly produce the gummy bears you want.

Luckily, you've come to the right place. Here, you will learn the most important information about the gummy production equipment, and also the top 6 questions you need to answer before making your final purchase.

1. What is a Gummy Making Machine?

First of all, before you buy a gummy making machine, you must have a rough idea about its definition. So, here comes the first question, what is a gummy bear machine?

Simply put, it is a piece of equipment used to produce a variety of gummies. Depending on the amount of gummies you need and the production scale, bear gummy machines are also available in various sizes. Certain models take up little space and are suitable for small-scale production or home use. Bigger gummy production lines, however, are specifically designed for commercial or industrial use.

2. Which Ingredients Would You Like to Use for Your Gummy Candy?

There are many different ingredients for producing gummy bears. Based on the ingredients, the type of gummy manufacturing equipment you will need is also different. The three most common ingredients for making gummy candies are gelatin, pectin and starch.

If you're in the business of gummy candy production, it's important to understand the differences among these key gummy ingredients. Ultimately, this goes a long way in determining whether or not you can choose the right gummy production machine.

Gelatin

Gelatin is the most commonly used gummy material, so most gummy production equipment is well adapted to gelatin gummies. When used in making gummies, gelatine requires specific heating and cooling cycles. For this reason, you should choose a gummy making machine with heating system and temperature control function.

Pectin

In recent years, gummies made from pectin have become increasingly popular. This is because they are vegan friendly and give consumers a fresh taste. When choosing a production machine for pectin gummies, you should make sure the machine can meet the specific mixing and settling requirements of the pectin you are using.

Starch

If you are planning to make starch-based gummies, then you will need to purchase a gummy production machine with a starch molding system.

If you still can't decide which ingredient to use in your gummies, check out the table below. It shows you more visually the main differences between the three types of ingredients and their respective advantages and disadvantages.

|

Ingredient |

Source |

Setting Method |

Texture |

Advantages |

Disadvantages |

|

Gelatin |

Animal collagen, usually cow or pig |

Set at room temperature |

Hard and elastic |

Versatile and easily available |

Not suitable for vegetarians, may contain allergens |

|

Pectin |

Fruit, like apple and orange |

Solidify after adding calcium |

Softer and chewier than gelatin |

Vegetarian friendly and naturally derived |

Require added calcium, may not be as readily available as gelatin |

|

Starch |

Plant, such as corn or tapioca |

Need special starch molding techniques |

Chewier and less bouncy |

Vegan and allergen-free |

Its unique texture requires a special technique to process |

3. What Size, Color, and Shape of Gummies You Want to Make?

There are so many different types of gummies on the market. The gummy bear machine you purchase should match the specific size, color, and shape of the gummy you intend to produce. Only in this way, you'll be able to efficiently get an accurate finished product.

For your reference, below we provide you with important information about common gummy sizes, colors and shapes.

Gummy Size

- Small (0.5-1.5 g)- Usually a bite-sized piece of gummy candy, perfect for snacking or adding to a mix.

- Medium (2-4 g)- These gummies are more substantial and satisfying to chew.

- Large (5+ grams)- This type of gummy candy is for those who like to eat in big chunks.

Gummy Color

- Red- Classic and versatile, often associated with flavors like cherry and strawberry.

- Green- Represents flavors such as green apple, lime or watermelon.

- Yellow- Reminiscent of flavors such as lemon, pineapple, or banana.

- Orange- Associated with orange and citrus flavors.

- Purple- Commonly used in grape, blueberry or other berry flavors.

- Multi-Colored- Can be used in individual gummies or layered gummies with different flavor combinations.

Gummy Shape

- Animal- Animal shaped gummies such as bears and worms are a classic for young and old alike. Most standard gummy making machines have molds in various animal shapes.

- Fruit- Common fruit shaped gummies include strawberries, cherries, and watermelon. They are usually associated with real fruit flavors.

- Novelty Shapes- Gummy bears in the shape of hearts, letters, or cartoon characters are suitable for specific occasions or themes. These gummy bears may require a gummy maker equipped with custom molds.

4. How Much Capacity Do You Need for Your Gummy Making Machine?

Before deciding to purchase a gummy production machine, you need to determine the required production volume. At this point, you must consider both your current sales volume and your target market. How many gummy candies do you need this machine to make for you? Do you aim to produce in high volumes to fulfill large orders? Or do you focus on niche markets or customized products?

In addition, the different levels of automation of a gummy making machine will also affect its production capacity. An automatic gummy machine can surely make more gummy bears than a semi-automatic one in the same amount of time.

Semi-automatic Gummy Machine

Semi-automatic Gummy Machine

Automatic Gummy Machine

However, semi-automatic fudge machines also have their advantages. So, which one should you choose that best suits your output? Take a look at the table below. It compares the differences between these two types of gummy bear machines. We hope it will inspire you when choosing your machine.

Automatic Gummy Machine VS Semi-Automatic Gummy Machine

|

Feature |

Automatic Gummy Machine |

Semi-Automatic Gummy Machine |

|

Production Volume |

High production volume, ideal for large-scale production requirements |

Medium production volume, suitable for small businesses or start-ups |

|

Cost |

Much more expensive due to complex engineering and advanced functions |

More affordable with fewer functions, which reduces the initial investment cost |

|

Labor |

Require minimal manual intervention, thus reducing labor costs |

Require certain manual operations such as filling the hopper, pouring the mixture, and taking the gummy out of the mold. |

|

Occupied Space |

Need more space to accommodate the size of the machine and various add-on devices |

Compact machine requiring less space |

|

Maintenance |

Complex machine design requires skilled technicians for maintenance and repairs |

Easier to maintain and requires less technical expertise |

5. 2D or 3D Mold, Which One Do You Want to Use?

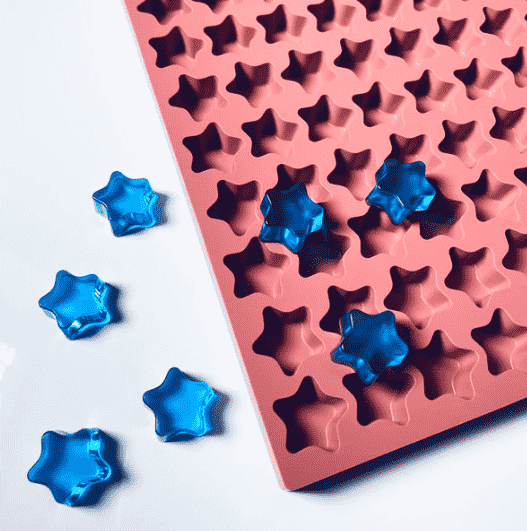

The exact shape and size of gummies you want is usually achieved by using various molds. For a gummy making machine, two types of molds can be used with it, 2D and 3D.

2D Mold

2D molds are flat. A single pattern is engraved on one side and the other side remains flat. A 2D mold is simpler to design and construct than a 3D mold. So, it's also usually less expensive than 3D molds. Simple gummy shapes like bears, worms, and numbers can be made using these 2D molds. But if you want more complex shapes, it may not be able to help you realize them.

3D Mold

3D molds create gummy candies with depth and detailed shapes. Their designs are usually more intricate and detailed compared to 2D molds. If you want your gummy shapes to be more unique and innovative so that your product stands out in the marketplace. Then, 3D molds are ideal choices. However, due to their intricate details, they may require extra care and attention during use and cleaning.

6. What is the Temperature Setting for a Gummy Manufacturing Equipment?

For this question, the operating temperature of a gummy manufacturing equipment is not actually fixed. It requires a range of different temperatures at different stages throughout the production process.

General Temperature Settings for Gummy Makers

Melting Stage

This stage involves melting the gelling agent and mixing it with other ingredients such as sugar, water and flavors. Depending on the gelling agent, the temperature ranges between 70°C and 110°C. Gelatine is usually melted between 80°C and 100°C. Pectin requires a higher melting temperature. Pectin requires a higher melting temperature, usually around 100°C - 110°C.

Molding Stage

After melting, the mixture is poured into the mold. A slightly lower temperature is used in this stage, usually around 50°C to 80°C, to facilitate pouring and prevent premature solidification.

Cooling Stage

The last stage is to allow the fondant to solidify. This is usually done at room temperature, around 20°C or slightly lower, depending on the desired texture.

Final Word

If you are planning to buy a gummy making machine to start your gummy business, you should have a new and deeper understanding of this machine after reading this article on 6 questions you need to answer before buying gummy production equipment. Choosing the right gummy bear machine is an important investment for your business. So take the time to research your options in depth, consider your specific needs, and choose a machine that performs well and last.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche