HFFS Machines Explained: Key Parts, Principles & Selection Tips

When making capsules, the packaging also needs to be considered carefully. Common packaging types include bags, boxes, bottles, etc. To get multi packaging functions in a machine, many manufacturers choose an HFFS machine to complete the packaging. This post will help you gain a further understanding of this machine. Then you can decide if it suits your business or not.

What is an HFFS Machine?

An HFFS machine stands for horizontal form-fill-seal machine. It can be used to deal with the continuous process of packaging, filling, and sealing. The whole process is completed in a horizontal orientation. The machines use a roll of packaging film to complete the packaging. And the film can be formed into different shapes, such as pouches, bags, sachets, or containers, etc. The shape and size of the package can be customized based on your production needs.

HFFS machines are known for their high-speed operations. This significantly increases production efficiency, making them ideal for high-volume productions.

Applications of HFFS Machines

HFFS machines have a wide range of uses. They are able to package a wide variety of products. Some common applications include

- Pharma packaging. HFFS machines can pack tablets and capsules of individual doses in blister packs or sachets. For powdered or granulated medications, it is also useful. In addition, liquids and gels can be packaged in sachets or small pouches.

- Food industry. Examples contain chips, candies, yogurt, milk, etc.

- Cosmetic packaging. It is mainly for beauty and personal care products, such as sunscreens, body lotions, conditioners, etc.

6 Common Parts of an HFFS Machine

Forming Station

The forming station is where the roll of film is shaped into the desired package form. In this part, the film is unwound and fed into the machine. The film can be made from various materials such as plastic, aluminum foil, or laminated composites.

Filling Station

In this stage, products are dispensed into the formed package. This process must be precise to ensure consistency and avoid spillage. There are many physical states of products, like liquid and powder. So the machine uses various methods, such as gravity, pumps, and augers, to complete the process. For example, nozzles might be used for liquids. Augers or volumetric cups might be used for powders.

Sealing Control

The sealing station ensures the package is securely closed to protect the product inside. The sealing process can vary based on the material and package design.

- Heat sealing. This is the most common for plastic packaging. It uses heat and pressure to fuse the package's edges.

- Ultrasonic sealing. This method doesn’t need heat for processing. It uses ultrasonic vibrations to create a strong seal. Ultrasonic sealing is a good choice for suitable for sensitive products.

- Adhesive sealing. Some packages may use adhesives to seal, particularly for materials that don't respond well to heat.

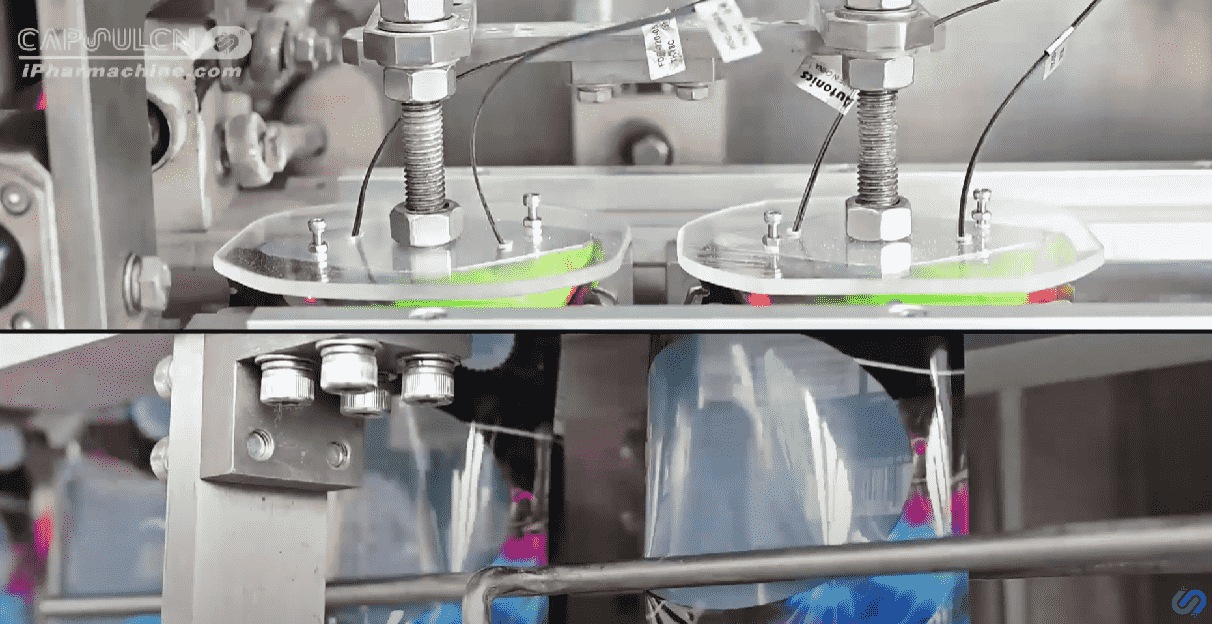

Mechanical Devices

Mechanical devices can control motors with the help of electrical and pneumatic systems. They work together to perform various operations, such as opening, spreading, and clamping bags. These devices use either regular motors or servo motors. Regular motors drive cams and linkages to perform cyclic movements for specific functions. In contrast, servo motors are more precise. And they are often used in bag transfer systems to control bag movement accurately.

Electrical Control System

The electrical control system consists of the main motor, transformer, heating device, and other electrical components. It is the brain and nervous system of the entire equipment. It controls and coordinates all parts of the machine, making it run efficiently and accurately. The core component of the machine is the PLC. It receives signals from sensors and the operating interface. Then it controls various machine actions based on preset program logic.

Additionally, you can use the PLC to monitor and process real-time data. It can ensure accurate and efficient machine operation.

Pneumatic Control

This system uses compressed air to control and perform various mechanical actions. It works together with the electrical control system to ensure efficiency and accuracy. The core of the pneumatic control system is the compressor. It compresses air and stores it in an air tank, providing a stable air source.

Another important part are cylinders. Cylinders convert the energy of compressed air into linear motion. The pistons in the cylinders, driven by compressed air, can perform actions such as bag clamping, opening, and air blowing.

To ensure safety, the system is equipped with a pressure regulator. It ensures that pneumatic components operate within a safe pressure range. This helps prevent damage from excessive pressure.

How Does an HFFS Machine Work?

For the whole packaging process, you can check the video to see clearly. Here let’s find how out it works step by step.

Step 1: film unwinding

At first, a roll of film is placed by hand on the unwinding shaft of the machine. Then the film is fed into the machine. It is positioned horizontally and directed to the forming section. From there, the tension control system, guide rollers, and sensors take over the film. They maintain the correct film tension and alignment. It helps ensure high-quality packaging with minimal manual intervention.

Step 2: package forming

Next, the film is guided through a forming station. In this place, it is shaped into a pouch like a flat pouch or container. The forming station can create most of your desired pouches like gusseted pouches and stand-up pouches. Then, the heat is applied to form the shape of the container.

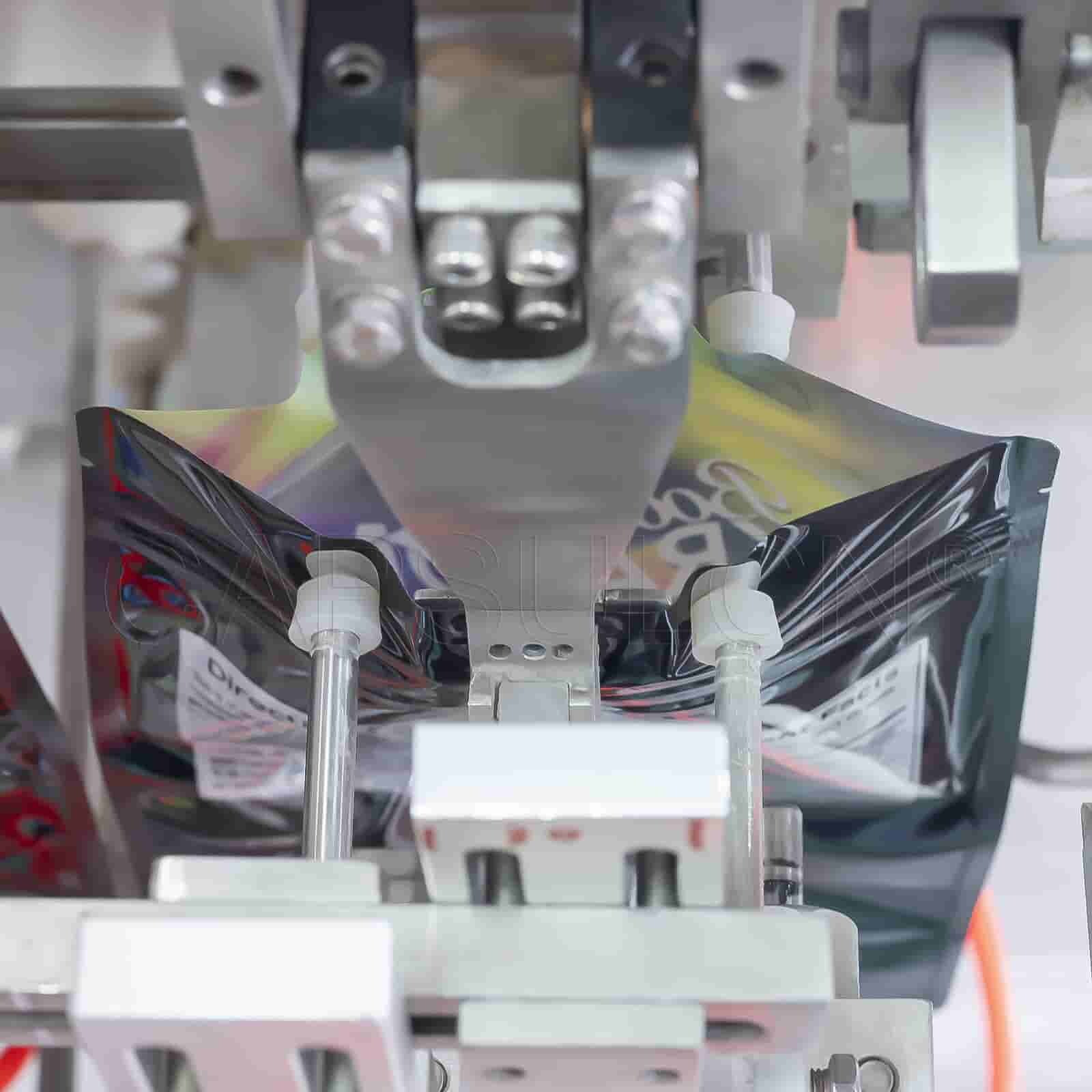

Step 3: product filling

Once the pouch is formed, it moves to the filling station. The products that need to be packaged would be dispensed into the pouches. For solid products like powders, they are always stored in a hopper for dispensing. For liquids and semi-liquids, tanks or reservoirs are used.

A controlled feeder system conveys the products from the hopper to the filling station.The filling mechanism dispenses the product into the pouch. There are many types of dispensing mechanisms, such as volumetric fillers, auger fillers, etc. This system can control the flow rate and amount of product, ensuring each pouch is filled accurately.

Step 4: sealing

After filling, it also needs to be sealed. This is usually done using heat sealing. The heated bars apply pressure and heat to bond the film layers together. For some types of HFFS machines, they may provide vacuum sealing, gas flushing, or resealable zipper closures. You can choose the most suitable one according to your requirements.

Step 5: product output

At last, the finished pouches are discharged from the machine. They are then collected for further processing such as labeling, coding, or secondary packaging.

How to Choose an HFFS Machine?

If you want to buy an HFFS machine, the following factors must be considered carefully.

Product Types

A packaging machine must fit your goods category. Different HFFS machines are designed to handle specific types of products.

- Liquids and semi liquids. You should hoose machines with liquid fillers and appropriate sealing mechanisms to prevent leaks.

- Powders and granules. They are suitable for machines with auger fillers or volumetric fillers.

- Larger solids. You should make sure the machine can handle the size and shape of larger solid products, such as candy bars, hardware items, etc.

Packaging Materials

There are many materials for packaging to choose from. Different materials have distinct properties and requirements. They can affect the machine's performance and the quality of the final product. So you need to ensure the machine can handle the specific type and thickness of plastic film you plan to use.

Packaging Styles

For common packaging types like fat pouches, most HFFS machines can produce them. But for some specific pouches and bags, you’d better choose the most suitable one. Take stand-up pouches for example. They feature a stable bottom that allows them to stand upright on shelves. So to make this design, the machine should be equipped with a specialized forming station to create the gusseted bottom.

Three Key Differences between HFFS and VFFS Machines

VFFS machines are another popular packaging machine in many industries. VFFS stands for vertical form fill seal. There are 3 differences between them and HFFS machines.

Different Working Principles

Compared to HFFS machines, VFFS machines complete the whole process in a vertical orientation. The film is pulled downwards and shaped into a tube for forming bags. Then the machine creates a horizontal seal at the bottom to form the bottom of the bag. Next, dispense products and seal the bag. Finally, the products are discharged to collect for further processing.

When talking about the filling mechanism, VFFS usually has one specific filling system. They can only deal with a certain type of product, like granules, liquids, or powders. By contrast, HFFS machines can be equipped with multiple filling systems. This versatility makes HFFS suitable for a wider range of products.

Various Product Types

VFFS machines are often used for free-flowing products like snacks, coffee, rice, and small hardware items. It is suitable for granular, powdery, and liquid products that can be easily gravity-fed into the bag.

HFFS machines are more versatile in terms of product types. It can handle a wider range of products. They include more complex shapes, larger items, and delicate products that require gentle handling.

Different Packaging Styles

VFFS machines feature a vertical seal when producing produce bags or pouches. Common styles include pillow bags, gusseted bags, and block-bottom bags. In contrast, HFFS machines can produce a variety of pouch styles. They contain flat pouches, gusseted pouches, stand-up pouches, etc. The pouches can also integrate features like resealable zippers and spouts.

Upgrade Your Packaging Solution with iPharMachine

In conclusion, HFFS machines offer a versatile and efficient solution for various packaging needs. They are capable of producing a wide range of pouch styles. So they are ideal for manufacturers looking to improve productivity.

At iPharMachine, we offer a comprehensive selection of HFFS machines. No matter what type of packaging you need, they can get the job done efficiently. Our machines are built to the highest standards, ensuring reliability and performance.

In addition, we pride ourselves on providing exceptional customer service. We can provide professional technical training for you. If you have any questions during the operation, feel free to contact us. We will help you find the cause and fix the problem.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche