How Does Honey Packaging Boost Your Business?

There has been an increasing demand for honey or syrup in recent years. So attractive packaging is beneficial to make your products popular in the market. It not only protects your goods but also makes them more appealing to customers. This post helps you know more about honey packaging and machine choices.

What is honey packaging?

Honey packaging mainly refers to the process of filling, sealing, and labeling. This involves the selection of proper machines to achieve a good result. These machines have different functions in the manufacturing. Good packaging prevent honey from environmental effects like moisture, and contaminants. It also helps prevent crystallization and spoilage. Airtight seals keep honey fresh and retain its natural aroma and flavor. Modern packaging increasingly uses recyclable or biodegradable materials. This meets more consumer who require eco-friendly packaging.

Five popular types of honey packing

Honey packaging types vary in design and material. Each features unique benefits suited to different needs. Here’s a look at common types of honey packaging.

Jars

Honey jars are one of the most traditional packaging types. They are always glass or plastic. Glass jars are more popular for honey. Because they have an elegant look and clear visibility of the honey inside. Glass is also great for preserving honey’s quality due to its non-reactiveness. It won’t interact with honey or affect its flavor. In comparison, plastic is more light and less likely to break. This makes them ideal for transport. Both jar types can come with twist-off lids, providing an airtight seal to protect the honey.

Bottles

Honey bottles often have a squeezable design with a flip-top cap. It makes them convenient for everyday use. These bottles are usually made of plastic, making them easy to handle and store in the kitchen. The squeezable feature allows consumers to control the amount of honey dispensed, reducing mess and waste. Some honey bottles are designed to stand upside down, ensuring honey flows easily. This also reduces the wait time for the honey to come out.

Sachets

Sachets are small, single-use packets. They are mainly manufactured for hotels, cafes, or for on-the-go use. These slim pouches hold just enough honey for a single serving. It makes them convenient for travel or adding to tea and coffee. Sachets are always made from lightweight materials like plastic or foil. So they are easy to store and transport in bulk. However, they’re typically disposed of after one use, contributing to more packaging waste.

Sticks

Honey sticks are thin, straw-like tubes filled with honey. Each stick can be opened by cutting or tearing one end. They are widely popular for their convenience and kid-friendly design. Honey sticks are commonly used for snacks, and their small size makes them easy to carry around. They’re a practical choice for people who want a quick honey treat. They are also suitable for those who need a measured amount of honey for drinks.

Pouches

Honey pouches are similar to larger versions of sachets. They are flexible bags that can hold a large amount of honey. These pouches often come with resealable spouts, making them easy to pour from without spills. Pouches are always made from lightweight materials like plastic and aluminum foil. They are preferred because of reduced shipping costs compared to heavier containers. Pouches are more convenient to squeeze and store than jars or bottles. this makes them suitable for both personal and commercial use.

Six common equipment used for honey packaging

There is a series of machines involved in honey filling and packaging. Filling machines measure and pour honey into containers accurately. Sealing and capping machines secure the container to prevent leaks and keep the honey fresh. Labeling equipment applies stickers or labels that display important information such as brand, flavor, weight, and nutrition details. All of them have different types to be used for different styles of honey packaging. Here are some common ones.

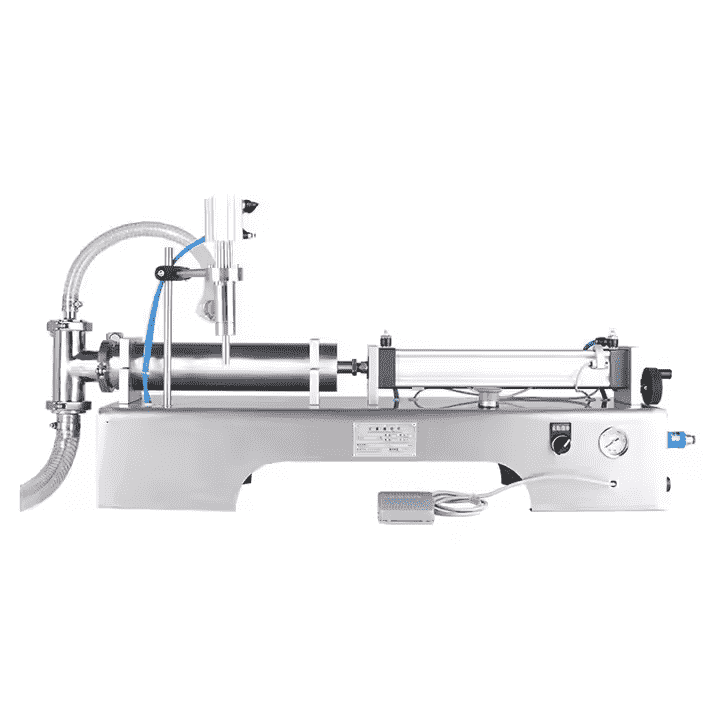

Piston filling machine

This liquid filling machine is specifically designed to handle viscous liquids like honey. It operates by using a piston mechanism to draw honey into a cylinder. Then it pushes the honey into containers like jars. Due to honey's thick consistency, piston fillers are ideal because they provide precise control over the amount dispensed. This ensures each container has an accurate fill level. In addition, most piston honey filling machines are designed for easy disassembly. It allows thorough cleaning to maintain hygiene.

Pump liquid fillers

This machine uses pumps to accurately move honey from a storage tank into containers. Unlike piston fillers, pump fillers rely on various types of pumps to work, such as gear, rotary, or peristaltic pumps. These machines are highly versatile. They are suitable for medium to large-scale operations, especially where flexibility and speed are highly required.

Induction sealing machines

This device is used to create airtight seals on containers. It applies a thin layer of foil or other sealant material to the container's opening. In most cases, this machine uses electromagnetic induction to heat the foil seal. Then the foil adheres to the container’s rim, creating a secure and tamper-evident closure. Induction sealing machines are commonly used in industries like food, beverage, pharmaceuticals, and cosmetics. They help maintain product freshness and prevent contamination or leakage.

Bottle capping equipment

Caps are the most important part of securing honey bottles and jars. Capping machines assist with cap placement and tightening. They support various types of caps, such as twist-offs, screw caps, tamper-evident lids, etc. Capping machines come in various forms to suit different production. They range from basic manual cappers for small operations to fully automated systems for large-scale production. If you want to balance cost with efficiency, semi-automatic models are good choices.

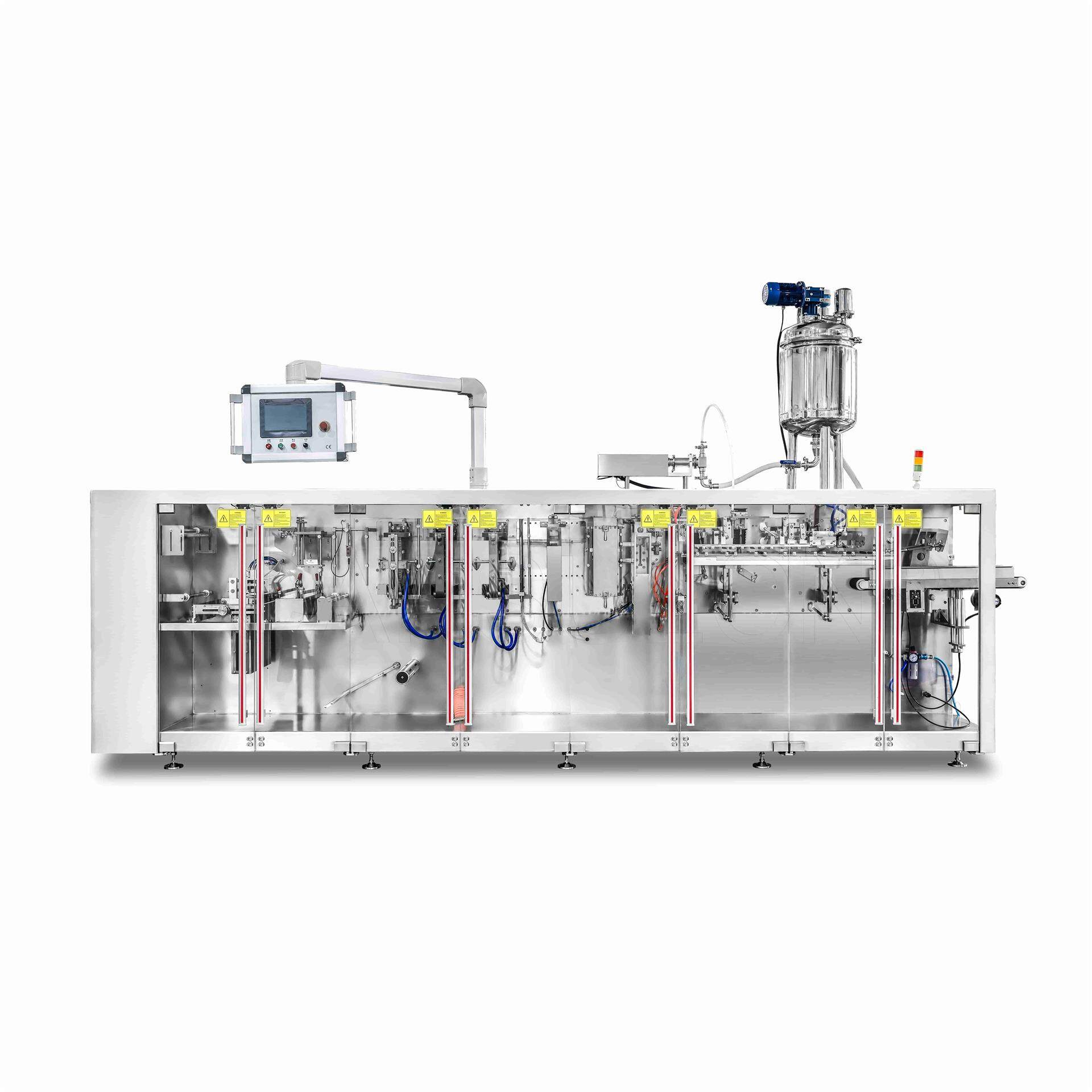

VFFS & HFFS bagging machines

VFFS machines stand for vertical form fill seal machines, and HFFS machines mean horizontal form fill seal machines. Both of them are automated packaging equipment used for filling and sealing bags, pouches or sachets. The key difference between them lies in the orientation of the machine. A VFFS machine forms, fills, and seals bags vertically, while the other operates in the horizontal direction. HFFS machines can handle more complex liquids, creams, or sticky items better than VFFS machines. In addition, VFFS is often used for smaller and single-serve pouches. HFFS is typically used for larger bags or bulk packaging.

Labeling machines

Labeling is necessary for whatever bag design you use for honey. Labeling machines apply various labels to different types of products and packages. Information includes branding, barcodes, ingredients, or instructions. Labeling machines improve speed, accuracy, and consistency in applying these labels. There are different types of labeling machines based on automation levels and functions. You can choose the one that suits your business best.

How to choose a proper honey packaging machine?

Packaging type

Different packing styles require different processing. If you want to make honey sticks or tubes, you should look for a stick pack machine designed to fill narrow, tube-like packaging. For bottles and jars, bottle filling equipment is more suitable.

Honey’s viscosity

Honey is thick and sticky, so make sure the machine has a viscous liquid handling system to prevent clogging or leakage. Machines with heated filling nozzles or piston fillers are typically more effective for thick liquids. Because they allow the honey to flow more smoothly. You can also look for machines with anti-drip features to prevent spillage during the filling process.

Production volume

For smaller businesses or those just starting out, a semi-automatic model is often a good choice. These require some manual assistance but are more affordable and suitable for lower production needs. If your business requires large-scale production, an automatic one will be more efficient. It is capable of higher speeds and reduced manual intervention. Automatic machines are ideal for operations where speed and volume are key.

Elevate your honey packaging with iPharMachine

If you are looking for the perfect honey packing machine to elevate your business, contact iPharMachine. We offer efficient and high-quality packaging solutions to meet your demands. Whether you're looking to package honey sticks or jars, iPharMachine has the right equipment to help your business thrive. Moreover, you can trust iPharMachine to provide solutions that meet various customization needs, such as packing shapes, patterns, etc. If you have any questions, feel free to contact us.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche