Introduction

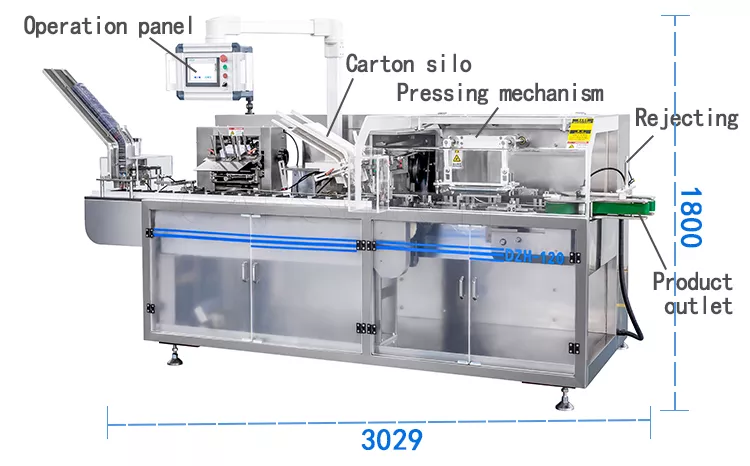

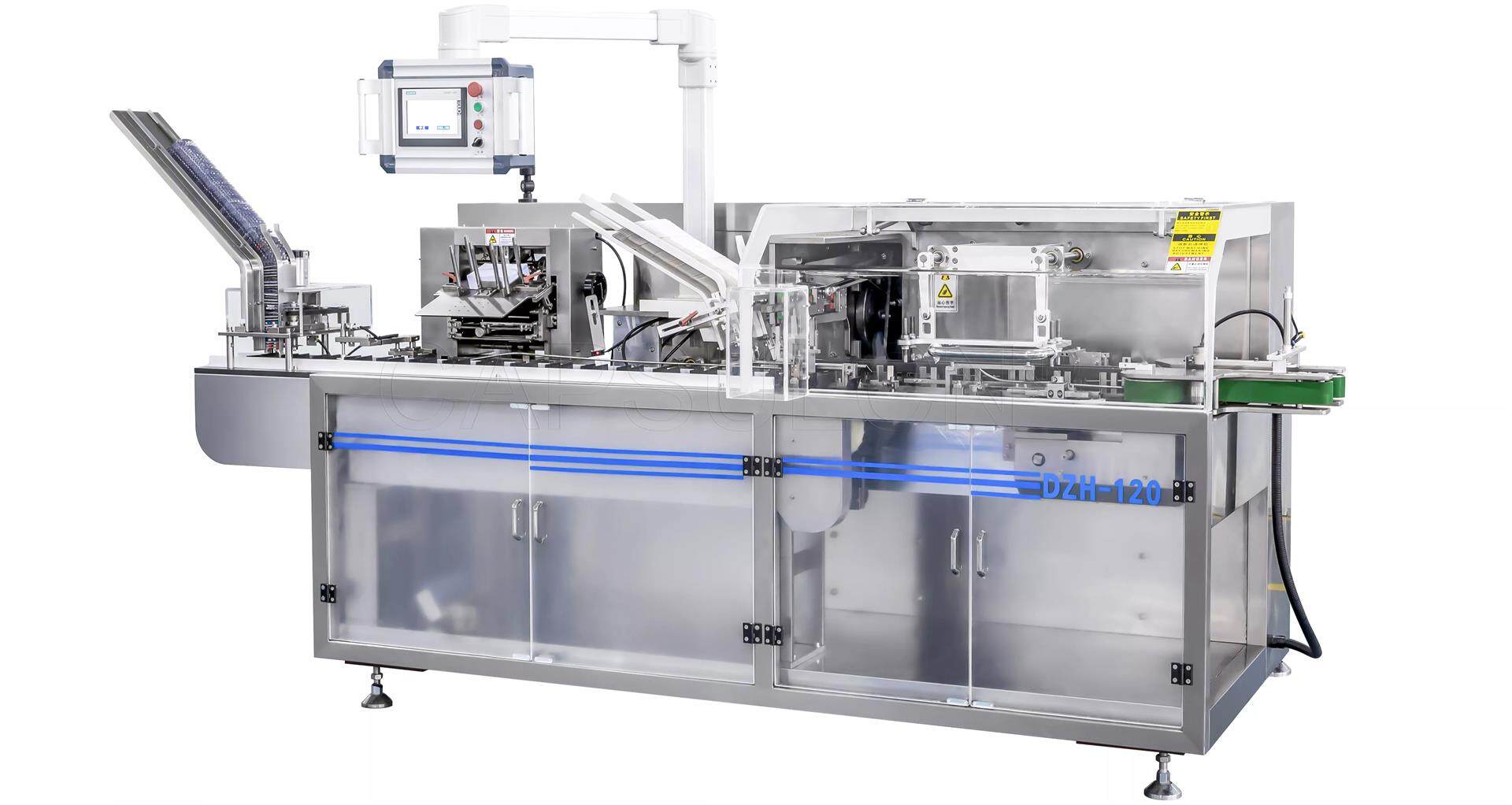

DZH-120 Horizontal Cartoning Machine is a new product developed by our company, which is a multi-functional cartoning machine integrated with machine, electricity and gas. It has the advantages of small size, light weight, wide application range, high production efficiency, and can be used for multiple purposes in one machine.

This machine is more suitable for pharmaceutical packaging. It can be used in-line with aluminum-aluminum, aluminum-plastic, aluminum blister, and pillow packaging machines. Stand-alone use. It meets the relevant requirements of "GMP" of "National Pharmaceutical Production Quality Management Standard".

Main Application

Specifications

| Model | DZH-120 |

|---|---|

| cartoning speed | 30-120 cartons/min |

| carton quality requirements | 300-350g/m² |

| dimension range of carton | (60-200)mm×(25-85)mm×(15-65)mm |

| user manual unfolded size range | L(80-300)×W(70-210)mm |

| user manual folded size range | L(70-210)×W(20-40)mm |

| total power | 220V 50Hz 1.5Kw |

| work pressure | 0.5-0.7mpa |

| air consumption | 15-20m³/h |

| dimensions | 3150 mm×1180 mm×1950mm |

| net weight of machine | about 1500kg |

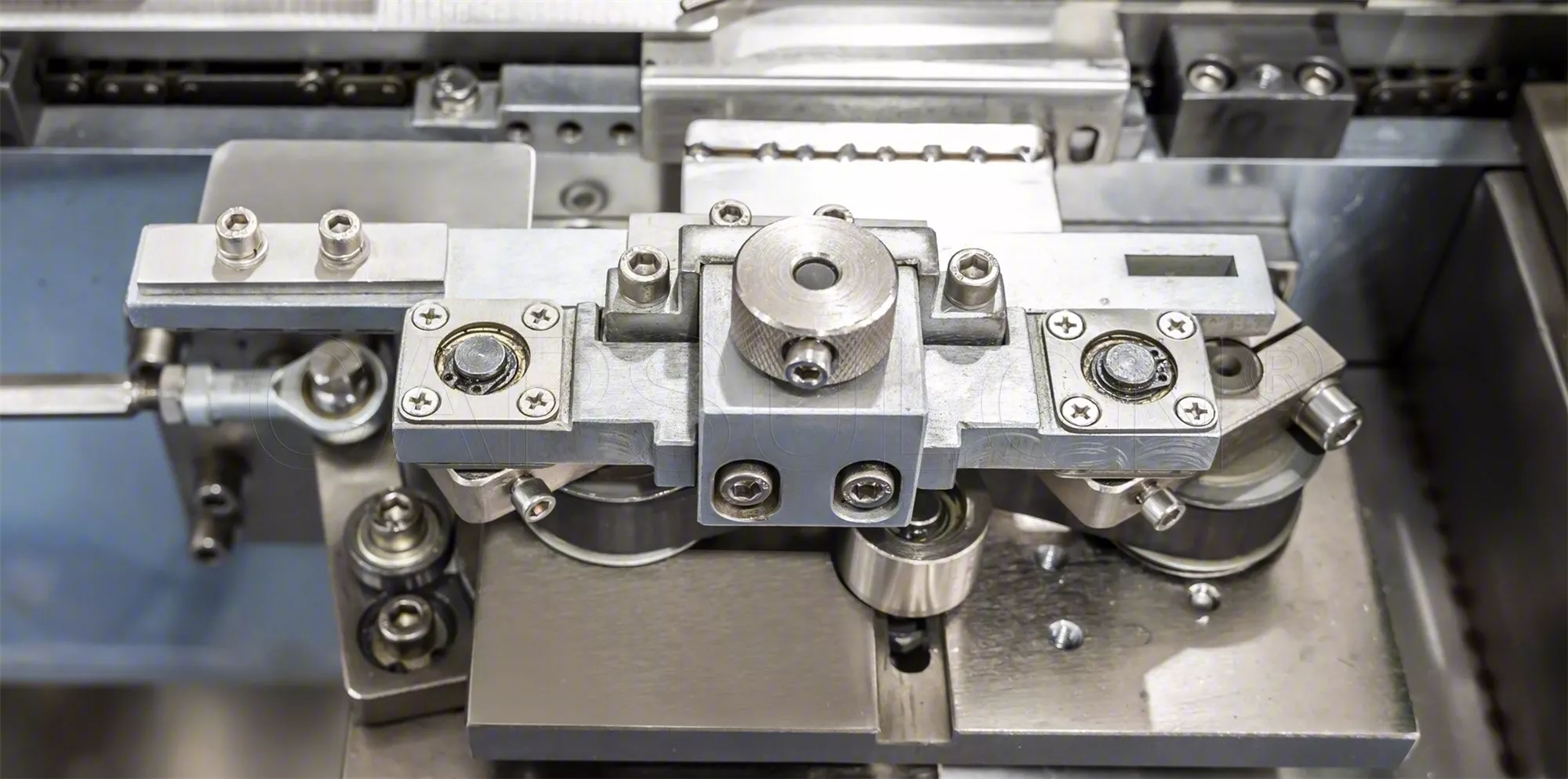

Details Images

Main Features

- The structure is compact and reasonable, the performance is stable and advanced, and the operation is simple and easy to understand.

- Intermittent motion, large packing range and easy adjustment.

- Using internationally renowned electrical components PLC control, which has touch-type man-machine interface, and the parameter setting is convenient and quick.

- The fault diagnosis prompt is clear at a glance, and the use is more user-friendly.

- The suction unit adopts a vacuum generator or a vacuum pump to realize the suction and put of the carton, the position is accurate, and the carton is not stuck.

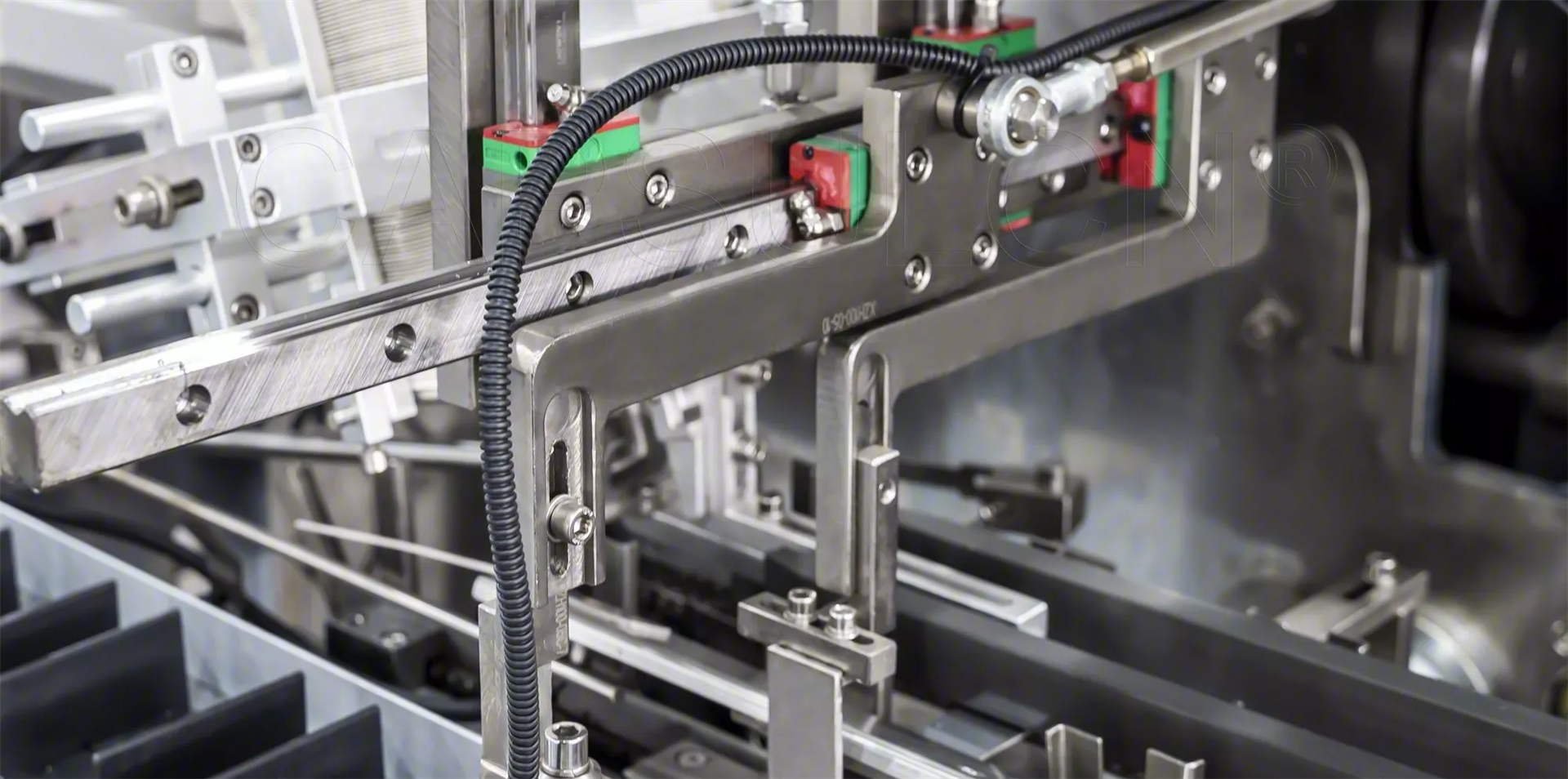

- The transmission system is concise and clear, the work is more reliable, and the maintenance is more convenient.

- Each control is realized by software, which is convenient for function adjustment and technical upgrading, and can adapt to the production needs of different periods.

|

|

| Machine body part The whole body is composed of high-quality stainless steel, Acrylic, and endurance board. Simple and atmospheric, hygienic and easy to clean. The transparent door is designed to monitor the operation of the machine while ensuring the safety of the operator. |

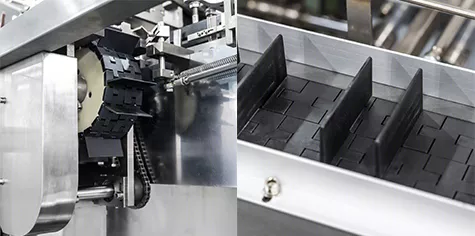

Feeding and conveying part The feeding and conveying part is driven by a three-phase asynchronous deceleration motor, and the conveyor belt is driven intermittently by the dividing box and the chain drive. The width between the chain-type grid belts can be adjusted to adapt to different specifications of materials. |

|

|

| User manual blanking part The user manual blanking part of DZH-120 is driven by a gear reduction motor, and the paper folding machine and paper feeding chain are driven by the chain drive. |

Carton blanking part Composed of carton compartment, carton suction unit and transport chain-type grid belts. The size of the carton compartment is adjustable, and it is suitable for a large range of cartons and is easy to adjust. |

|

|

| Pushing part Stably complete the pushing action of the material and the manual. |

Carton sealing part There are three tongue closing plates on the connecting plate, so that the whole box sealing action can be divided into three steps, that is, bending, inserting the tongue, and sealing. |

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche