How to Choose Labeling Machine

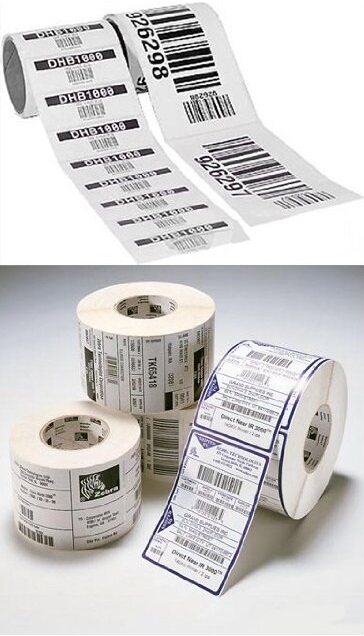

Now the labeling machine has covered all areas of our life, food, medicine, cosmetics and other industries. Visible labels have a huge role in our lives. After the product is labeled by the labeling machine, the corresponding product information of the consumer can be provided. According to this information, consumers can find its shelf life and determine whether it is safe. Purchasing a suitable labeling machine is critical for manufacturers.

1. Choose it according to the characteristics of the industry.

Some industries have some special requirements for machinery and equipment. For example, the food industry has strict requirements on commodity hygiene. Therefore, the related production and packaging equipment is required to be made of 304 stainless steel and aluminum alloy. It needs to be corrosion-resistant and resistant to rust and meets the requirements of GMP production. The food production generally requires an online coding device to print the date of manufacture and the batch number on the label to achieve integration of labeling and coding. Therefore, the labeling machine also needs to meet its hygiene requirements. Another example, inflammable and explosive industries such as petrochemicals are particularly concerned about production safety. Labeling machines used in this industry require safety measures such as anti-static and explosion-proof. In general, there are many labeling machines for the industry on the market, and priority should be given to special labeling machines belonging to the industry.

2. Understand the needs of production.

Production requirements include the number of specifications of the product, the production and production efficiency of the product, the requirements of the label, etc. There are many types of labeling machines on the market, such as multi-function labeling machines, simple labeling machines with special functions, high-performance labeling machines, and so on. But the choice of labeling machine is not the more powerful, the better the performance. Blindly asking for some functional configurations that are not available in their own production will cause unnecessary waste. When selecting a suitable labeling machine, in consideration of the product upgrade, it is necessary to select the product that can meet the labeling output of the product and the labeling accuracy requirements of the product.

3. Ask supplier for help.

If the purchaser does not understand the performance and application of the labeling machine, the sample that needs to be labeled and sample label should be sent to the labeling machine manufacturer for evaluation and testing as much as possible to confirm the compatibility of the labeling machine manufacturer with its own products, and whether the printing module requirements can be achieved to reduce the risk of purchase feasibility.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche