A Comprehensive Guide on How to Press Pills

Tablets are a type of pill. They are solid dosage forms by compressing powdered ingredients. This compression method is widely used for producing medication, supplements, and similar products. The process is quite straightforward. Yet, there are a few factors to consider to get a high-quality final product.

Do you want to improve the quality of your tablets? Don't miss out on this guide. It provides you with all the necessary knowledge on how to press pills successfully. Also, you can learn the necessary materials and the steps involved in the pressing process. Now, let's dive in!

What Do You Need to Press Pills?

If you want to make tablets, you will require various components and specialized equipment. The specific components and equipment needed will vary based on the tablets being produced, as well as the drug formulations. Below are some of the critical elements you'll need to press pills:

1. Active Pharmaceutical Ingredient (API)

The API is the main ingredient in pills. This ingredient provides patients with the desired therapeutic effect. It comes in either a synthetic or natural compound tested for pharmaceutical use. To press pills, the API must be properly mixed with other excipients, such as fillers and binders. This ensures even distribution of these ingredients throughout the tablet.

2. Excipients

In addition to active ingredients, inactive ingredients are must-haves when pressing pills. An excipient is such a substance. This inactive ingredient contributes to the physical properties of tablets.

Common tablet excipients include:

- Fillers

- Binder

- Lubricants

- Disintegrants

- Coloring agent

Additionally, excipients are crucial to the delivery of the tablet formulation, helping enhance your products' stability and shelf life.

3. Tablet Press

A tablet press is what you need to press pills. This machine is typically available in two styles. They are single-punch and rotary tablet presses. Both are widely used for pressing pharmaceuticals, nutraceuticals, and beauty pills.

|

|

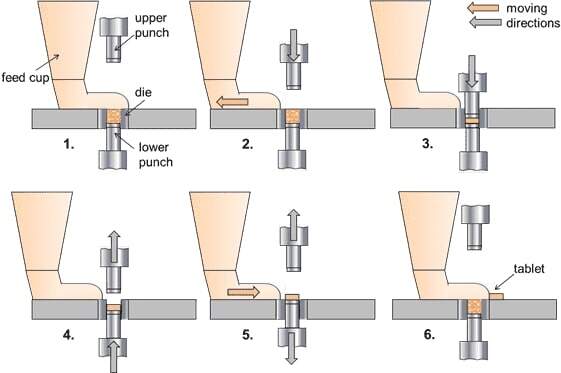

Prior to pressing pills, granulated powders are evenly distributed into a die cavity. Once the die cavity is filled with material, the upper and lower punches of the tablet press compress the material within the die to form a tablet.

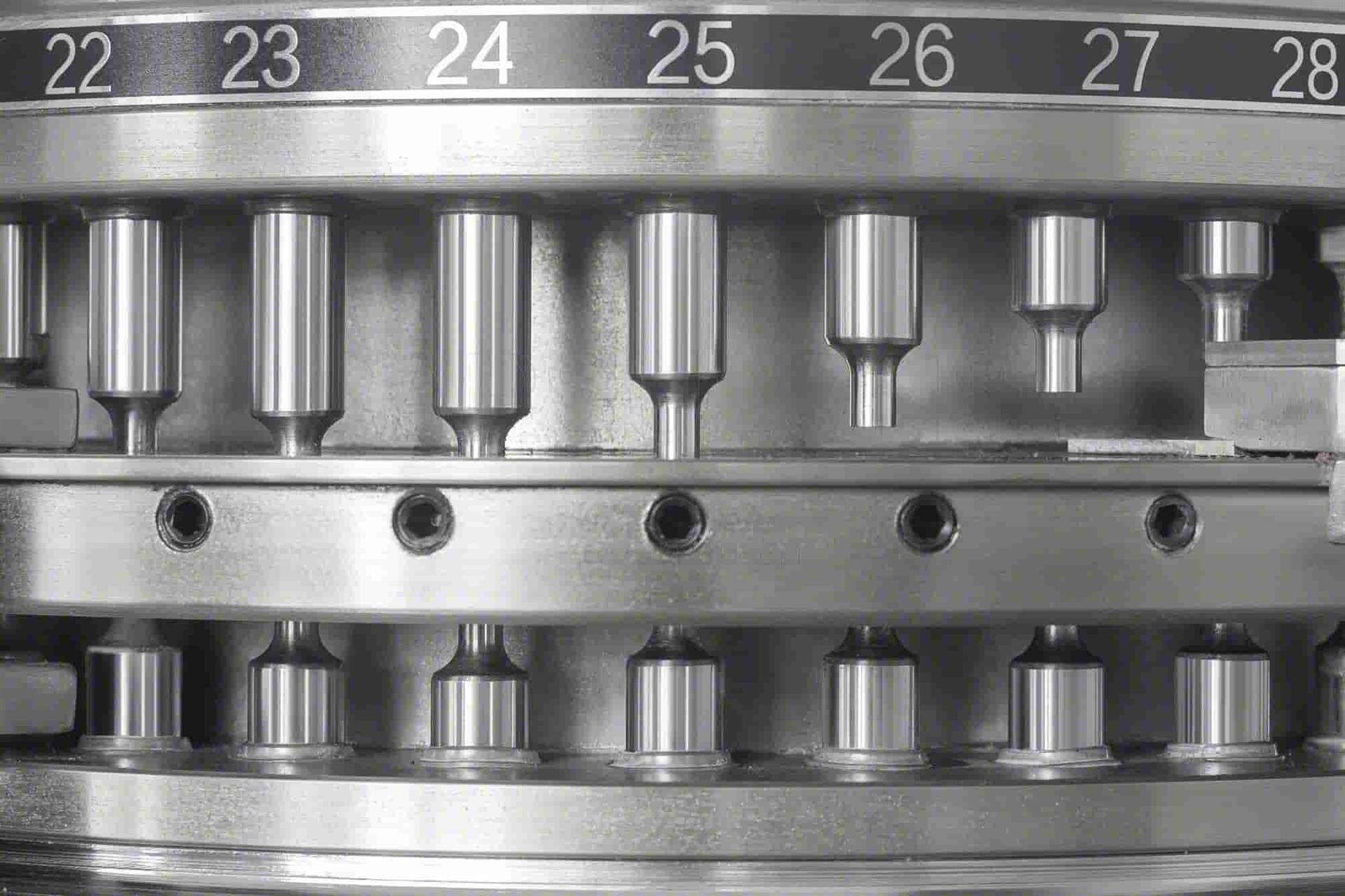

4. Tooling

The upper and lower punches and die mentioned above are all called tooling in a tablet press. A standard set of tooling typically includes an upper punch, a lower punch, and a die. These three parts determine your tablets' sizes, shapes, and markings. Also, the tooling contributes to the consistency and quality of the final product.

There are mainly two recognized standards for tablet tooling:

- Tableting Specification Manual (TSM)

- Euro Standard (EU)

The former was developed and exclusively intended for utilization within the United States by the American Pharmaceutical Association. In contrast, the latter is primarily utilized in Europe, but its application extends globally.

The tablet tooling can also be divided into four types: B, D, BB, and DB, of which the last two are the subcategories of the first two sizes.

Here are two tables to help you get a clearer understanding of the tooling.

Table 1: Difference Between TSM and EU Standards

|

Specifications |

TSM Tooling |

EU Tooling |

|

Punch Head |

Angle profile |

Domed profile |

|

Inside Head Angle for B Tooling |

37° |

30° |

|

Overall Head Thickness |

Greater than EU |

Smaller than TSM |

|

Overall Punch Length |

0.010 inches shorter than EU |

0.010 inches longer than TSM |

Tablet 2: Different Types of Tablet Tooling

|

Tooling Type |

Barrel Diameter of the Punch (mm) |

Outer Diameter of the Die (mm) |

|

B |

19.00 |

30.16 |

|

D |

25.35 |

38.10 |

|

BB |

19.00 |

24.00 |

|

DB |

25.35 |

30.16 |

How to Make Tablets Using a Single Punch Press?

If you are involved in the manufacture of tablets on a small scale, utilizing a single punch press can significantly enhance your production efficiency. A single punch press is a manually operated tablet press machine. It uses a single punch and die set to produce tablets one at a time.

The single pill press is simple to use. The pill pressing process involves a series of straightforward steps as follows.

STEP 1: Prepare the granulated powder

Before starting the pill press, you should get the required granules prepared. Granulate and blend the active ingredients and excipients in the proportions based on your production needs. You can use a granulator to produce uniform-sized granules for easy compaction.

STEP 2: Load the powder

The next step is to load the hopper of the single punch press with the powdered material. As a crucial machine component, the hopper provides room to accommodate the granules to be pressed. If you're using a single punch press, you must load the powder by hand due to its manual operation nature.

STEP 3: Adjust the machine

The single punch press should be adjusted to the required settings before the compression process begins. The settings include the thickness and diameter of the tablet. Plus, the compression force and the fill depth can be adjusted by a handwheel installed on the side of the machine.

STEP 4: Compress the granules

This is the most critical step in tableting. Once the machine starts, the granules fall into the die cavity through the hopper and feed shoe. The punches exert pressure on the granules to form a tablet of the required shape, size, and thickness. The compression force is maintained for a specific time to compress the granules properly.

STEP 5: Eject the tablet

Once compressed, the tablet is discharged from the machine. The lower punch ascends to eject the tablet out of the compression chamber. Meanwhile, the feed shoe swings over the die for the next fill and propels the tablet downwards into a collection bin through the discharge chute.

How to Press Pills with a Rotary Tablet Press?

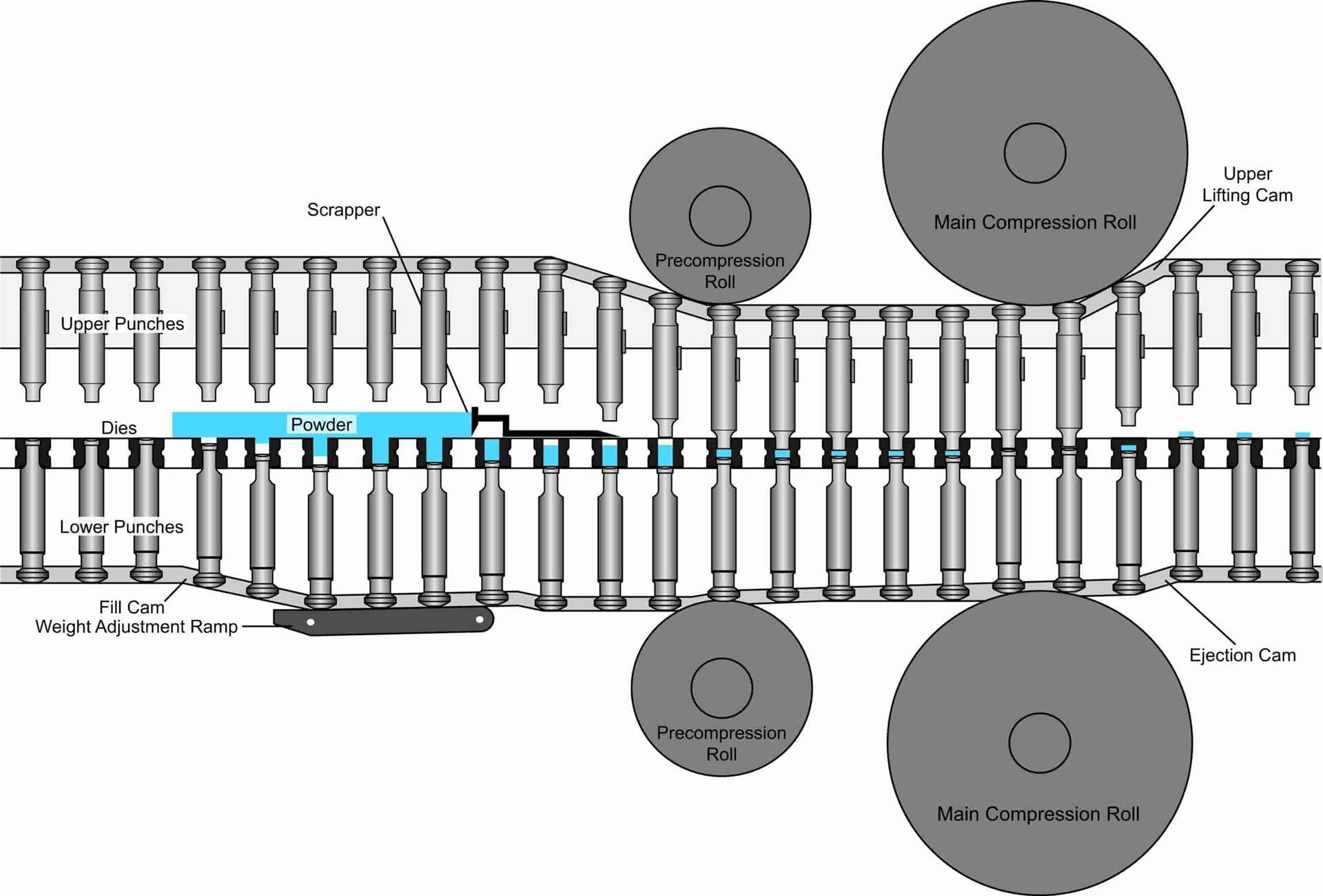

If you're handling a higher-volume operation, choosing a rotary tablet press is a dependable move. This highly automated device outperforms a single punch press in terms of efficiency and productivity.

Now, let's take a closer look at how to press pills using a rotary tablet press.

STEP 1: Prepare the powder

Getting the powdered material ready is the first step in tableting. The material is a homogeneous blend. It is formulated with APIs and other necessary excipients.

STEP 2: Feed the granules

Getting the powdered material ready is the first step in tableting. The material is a homogeneous blend. It is formulated with APIs and other necessary excipients.

STEP 3: Meter the powdered material

The material is metered into the feed frame. The feed frame is an important part of a rotary tablet press. This component ensures the correct amount of material is fed into each die cavity. Plus, the lower punch plays a big part in the metering step. The depth of the lower punch can precisely control the amount of powder metered into the die cavity. The metering step ensures each tablet is uniform in drug content and weight.

STEP 4: Compress the material

Now, it's the time for the punches to come into play. The upper and lower punches move against each other. This action allows the powdered material in each die cavity to be compressed. When the punches retreat, a tablet is formed.

STEP 5: Eject the tablets

Once the tablets are created, they jump out of the die cavity with the help of an ejection mechanism. The lower punch raises to push the formed tablets out of the die cavities. These tablets are then transferred into the discharge chute. Certain rotary tablet presses even have a rejection system to discard any defective tablets.

Key Factors to Consider When Making Tablets

Now you might have gained a clear idea of how to press pills. Yet, ensuring the uniformity and consistency of tablets can be a daunting task. So, if you want to guarantee the quality and efficacy of your tablets, pay attention to these important factors!

1. Material Properties

The properties of the material being compressed include particle size, density, and flowability. They can affect the quality and consistency of the tablets. Proper selection and testing of the APIs and excipients can help ensure successful tablet production.

2. Equipment

|

|

The condition and type of the tablet press and tablet tooling can affect the performance of the final drug product. So, how do you choose the right pill press and tooling? Consider your budget, production capacity, and floor space. In addition, be sure to keep your equipment in tip-top shape. Perform regular maintenance and calibration to optimize the performance and longevity of your tablet press.

3. Compression Force

The amount of compression force applied during pill pressing can affect the hardness, friability, and disintegration of the tablets. So, the compression force should be carefully controlled to ensure consistent tablet quality.

4. Dwell Time

The amount of time that the material is held under compression also has an effect on tablet hardness and disintegration. The dwell time should be optimized for the specific material being compressed.

5. Lubrication

Sticking and capping are common tablet defects. To avoid these issues, lubricate crucial parts of your tablet press on a regular basis. But attention! The type and amount of lubricant used should be carefully controlled. Otherwise, the tablet quality can be affected.

6. Temperature and Humidity

Environmental condition is also an important factor. The temperature and humidity in your facility can affect the raw material characteristics and tablet press performance. Proper environmental control is required to guarantee the quality of the final product.

The Bottom Line

We hope the above step-by-step instructions on how to make tablets can help you get the end products that meet all required specifications. Prioritize safety and quality control throughout the process, and seek expert advice whenever necessary. Remember these tips to ensure your pills are of the highest quality.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche