How to Use Capsule Filling Machine: A Step-by-step Guide

Capsule filling machines are crucial for the manufacturing industries— especially for the pharmaceutical businesses. However, picking them to use for a particular product can be challenging. There are many users who got confused about appropriately using the following machines:

- Manual capsule filling machines.

- Semi-automatic capsule filling machines.

- Automatic capsule filling machines.

It is why we are providing complete information on how to use capsule filling machines effectively. Please proceed with the reading and understand them better:

# How To Use A Manual Capsule Filler

# How To Use A Semi-Automatic Capsule Filler

# How To Use An Automatic Capsule Filling Machine

How To Use A Manual Capsule Filler

Manual Capsule Fillers: Manual capsule filling is a machine that is operated manually to fill the capsules. These are feasible to use for producing small to medium batch size requirements of the capsules.

Check out the best manual capsule machine from iPharmachine!

CN-100 Manual Capsule Filler By iPharmachine

Manual Capsule Filler CN-100 from iPharmachine is the perfect example of a manual capsule filling machine. It includes the manual handling of the device and filling the capsules. Here are a few characteristics of the capsule filler:

- The material used to build the machine is imported durable and safe acrylic.

- Stainless steel screws and pins are used that meet the GMP standards.

- U-design powder guard used for avoiding powder loss.

How Does A Manual Capsule Filling Machine Work?

See how to use a manual capsule filling machine like CN-100 properly:

STEP 1: The first step is to place the encapsulation plate on top of the cap plate.

STEP 2: Place the encapsulation plate on top of the body plate.

STEP 3: Adjust the powder guard over the body plate in the third step. It will help in avoiding the fall of powder by the sides.

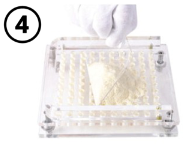

STEP 4: Fill the powder appropriately on the body plate with the use of a spreader.

STEP 5: Take the help of a tamping plate if the bottoms are not filled enough.

STEP 6: If still the bottoms are not filled, use the tamping plate.

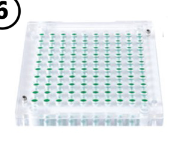

STEP 7: The following step is to remove the filled cap plate and place the middle sheet on the top. (NOTE: the hole with the bigger diameter of the middle sheet faces the cap plate.)

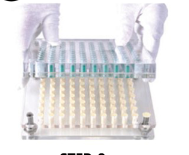

STEP 8: Now, place both your hands on the top. Apply the equal push downwards and ensure the bodies and caps match together before direct press down.

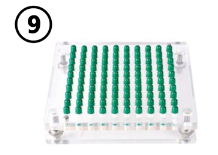

STEP 9:In the last step, your work is done, and you can see the results.

How To Use A Semi-Automatic Capsule Filler

Semi-Automatic Capsule Fillers. The semi-automatic capsule fillers have an automatic capsule loading system that ensures quick, safe, and better filled capsules. However, an operator is required to manage the end results.

Let us have a look at one of the best semi-automatic capsule machines by iPharmachine!

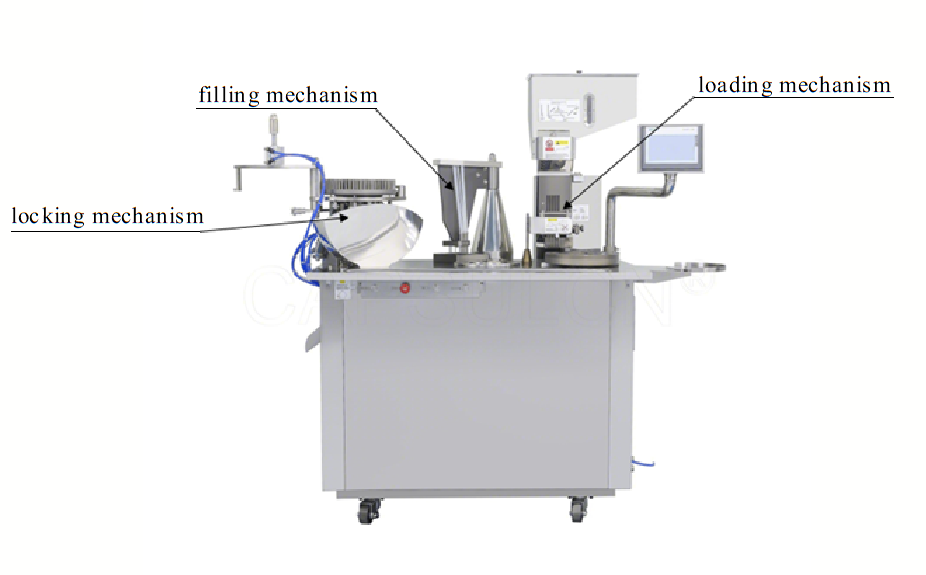

JTJ-V Semi-Automatic Capsule Filling Machine

The best example of a semi-automatic capsule filler is the JTJ-V semi-auto capsule filling machine. It is a liquid filling machine that has a variable frequency for speed regulation. The equipment is feasible to use for 00#, 0#, 1#, 2#, 3#, and 4#. Some characteristics of the machine are:

- 1-10800 capsules per hour (depends on capsule model & operational proficiency.

- PLC control system to enter the filling parameters.

- Simple structure that is easy to clean and maintain.

How Does A Semi-Automatic Capsule Filler Work?

To learn how a semi-auto capsule filler works, and familiarize yourself with the mechanism of semi-automatic capsule filling machine:

PART 1: CAPSULE LOADING MECHANISM

The first mechanism of the process involves the loading of the capsules. It consists of the insertion of hollow capsules into the capsule feeding tube from a hopper. A reed switch is under the capsule feeding tube. As the eccentric wheel drives the capsule loading tube to descend, the reed switch is activated and triggers the loading switch. Then it opens and releases a row of capsules.

Once the capsule loading tube rises upwards, the reed switch instantly stops the capsule loading switch. The fallen capsules on the capsule comb are pushed to a U-turn position. The capsule body faces down while the capsule cap faces upside.

PART 2: FILLING MECHANISM

When you learn about how to use a capsule filler machine, the filling mechanism of the machine is crucial. In this machine, this process involves pumping liquid into the material storage with the help of a peristaltic pump and moving it to the hole of the die plate through a feeding pipe.

The feeding nozzle gets pushed from cylinder to mold when the user presses the filling button. The peristaltic pump and turntable motor will start automatically when it is in the right place. After one turn, it gets stopped, and the cylinder pulls out the feeding nozzle and exits the mold.

PART 3: LOCKING MECHANISM

In this mechanism, the pin plate gets moved to the discharge hopper and transfers the liquid-filled capsule mold plate to the pin plate bracket. At this time, both upper and lower molds remain closed after a slight swing is done for the pin head to enter the mold hole.

Next, fasten the fixed powder and add pressure horizontally to the bottom of the panel. The pin plate simply moves to the discharge hopper, rotates the pin plate to the left, and in the end, capsules move out from the discharge port.

How To Use An Automatic Capsule Filling Machine

Automatic Capsule Fillers - An automatic capsule filling machine is fully automated and performs exceptional work in capsule production. Besides, there is no need for an operator with automatic capsule fillers.

Here is the introduction and working of an automatic capsule filler by iPharmachine:

NJP-7500C Automatic Capsule Filling Machine

If you need to find out how to use a capsule filler, you must see the process of a fully automatic capsule filling machine. NJP-7500C is an automatic capsule filler manufactured by iPharmachine. Check out some of its best features:

- The equipment is used for hard capsules size ranging between 0# to 5#.

- Several materials can be used, like powder, pellets, or granules.

- The maximum production capacity of the machine is 7500 pcs/min.

How Does An Automatic Capsule Filling Machine Work?

Below are the steps that details how an automatic capsule filling machine works:

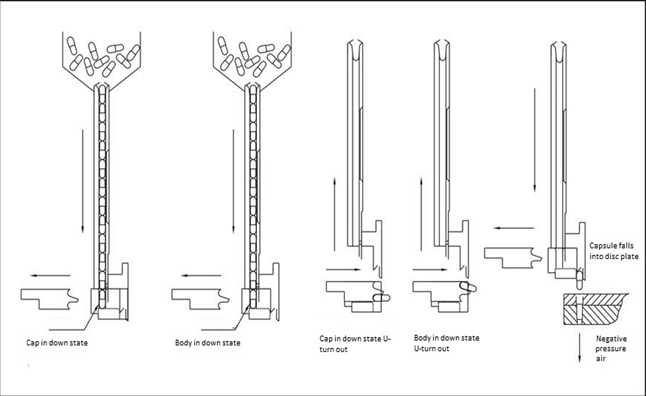

STEP 1: The capsules are present in the capsule hopper after starting. The capsules enter the capsule magazine one by one in the vertical direction.

STEP 2: As the capsule magazine descends, a line of capsules is directed toward the capsule comb.

STEP 3: By utilizing a horizontally-oriented fork to apply directional force and employing the capsule magazine, the turning process of the capsules is carried out. Ultimately, all capsules fall into mold bores with caps facing upwards and bodies downwards.

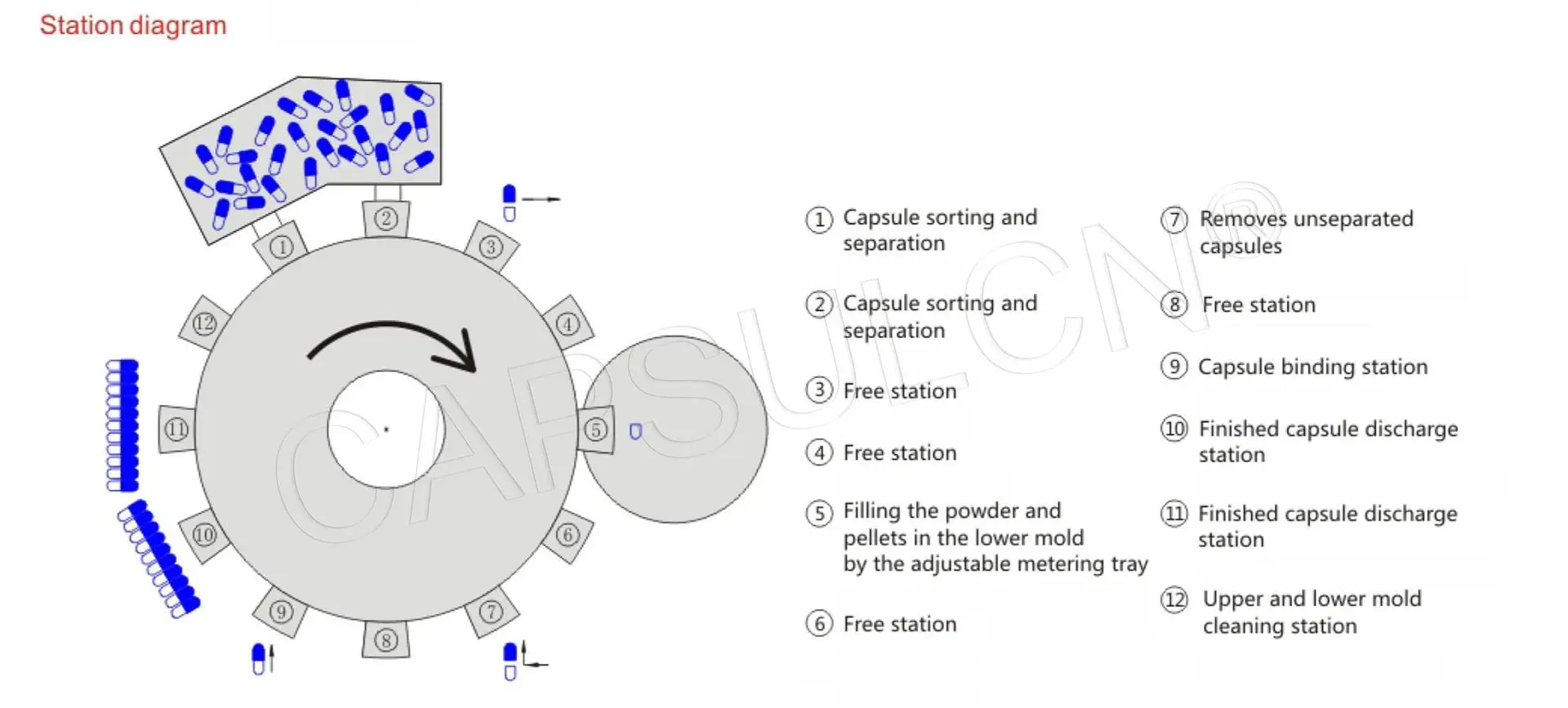

STEP 4: The vacuum separation system will operate at Stations 1, 2, 3, and 4. It will insert the capsules into the mold bores and simultaneously divide the bodies from the caps.

STEP 5:The bores of the upper mold rise at Station 5, while the lower mold bores at Station 6 protrude outward and are arranged in a staggered pattern with the upper mold bores to facilitate material filling.

STEP 6: At Station 7, the task is to extract and vacuum the capsules that have not been appropriately separated and are still together in the upper mold bores with their caps and bodies intact.

STEP 7:Capsules are loaded with materials at Station 8, while at Station 9, the upper mold bores descend, and the lower mold bores withdraw.

STEP 8: At Station 10, adding push to the pins works for making capsule bodies closer to capsule caps.

STEP 9: The function of Station 11 is to push out the completed capsules for gathering.

STEP 10: The vacuum cleaner operates at Station 12 to clean the mold bores and prepare for the next round of production.

Which type of capsule filling machine is right for you?

Every type of capsule filling machine has its own benefits and disadvantages. However, how to use a capsule filling machine is evident above. But the question here is which capsule filler should be picked. Well, it entirely depends on the type of business and its requirements.

Moreover, semi-automatic capsule filling machines are recommended by many users. It involves automatic elements for faster results. But it also has parts for the operators. If you want to choose one option, check your business. For large-scale companies, semi-automatic and fully-automatic are both excellent choices.

Conclusion

We have added everything you need to know about how to use capsule filler machines. But the most vital thing to know is the best capsule filling machine manufacturers. iPharmachine is one of the leading suppliers that has served hundreds of industries, including pharmaceutical, chemical, and more.

So, you can also trust the brand to get high-quality capsule filler for your business. Contact iPharmachine and purchase the most reliable capsule filling machine at the best price.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche