Video

Introduction

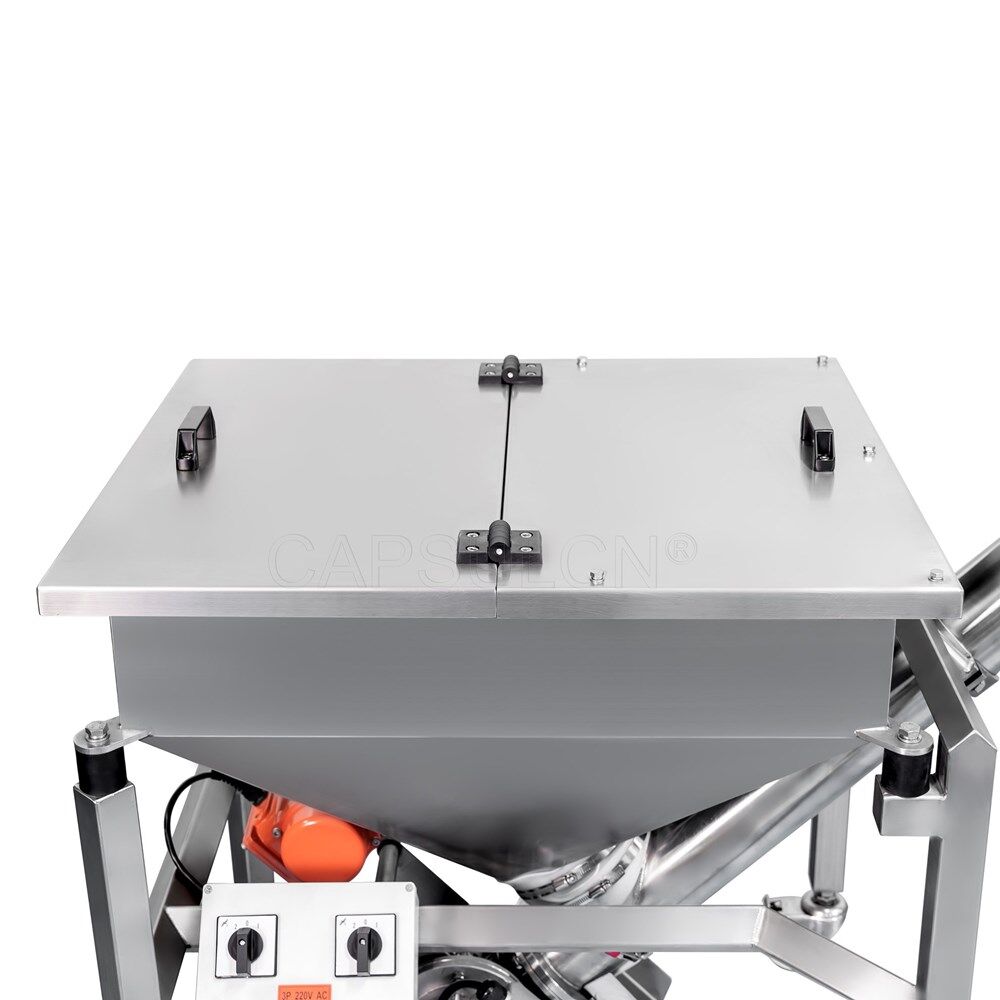

The HZF-S2 series bucket vibrating screw feeder mainly consists of a feeding motor, vibrating motor, hopper, screw, and feeding tube. Due to the vibrating screw conveying

method, the feeding tube can transport materials at a conventional angle of 45 degrees,

and it can also be customized to transport materials at other angles according to customer requirements. The conventional conveying speeds are 2m³/h, 3m³/h, 5m³/h, and 8m³/h. The lifting height can be customized from the conventional 1.85m to 1-5m according to customer requirements

Specifications

| Model | HZF-S2-2K | HZF-S2-3K | HZF-S2-5K | HZF-S2-7K | HZF-S2-8K | HZF-S2-12K |

|---|---|---|---|---|---|---|

| Lifiting Speed | 2m³/h | 3m³/h | 5m³/h | 7m³/h | 8m³/h | 12m³/h |

| Feeding Tube Diameter |

φ102

|

φ114

|

φ141

|

φ159

|

φ168

|

φ219

|

| Total Power | 0.58KW | 0.78KW | 1.53KW | 1.53KW | 3.03KW | 4.03KW |

| Total Weight | 100kg | 130kg | 170kg | 200kg | 220kg | 270kg |

| Hopper Capacity | 100L | 200L | 200L | 200L | 200L | 200L |

| Power Supply |

3P AC208-415V 50/60Hz

|

|||||

| Lifing Angle |

Conventional 45 degrees, customizable within 30-60 degrees

|

|||||

| Lifing Height |

Conventional 1.85 meters, customizable from 1-5 meters

|

|||||

| Hopper |

Conventional square bucket, customizable circular bucket or other volumes

|

|||||

| Note |

In addition to the listed conveying capacities, other conveying capacities, lifting heights, and power requirements can also be customized.

|

|||||

Remarks

-

During feeder operation, pay attention to the material level in the storage bin. If the bin is already full and the feeder continues to supply material, it may cause blockage at the outlet of the feeding pipe, damage the spiral blades, and even result in motor burnout. (It is strictly prohibited to continue operating the feeder in the event of a blocked outlet of the feeding pipe.)

-

If there is a blockage or obstruction in the feeding process, immediately stop theoperation. Open the discharge gate, reverse the feeding motor, and remove thematerial or debris that is blocking the feeding pipe. Clean the feeding pipe.

-

If any abnormal sound occurs in the feeding pipe during operation, stop immediately, cut off the power supply, lay the feeding pipe flat, carefully remove the spiral rod, and check if it is deformed or eccentric. If any issues are found, repair it accordingly.

-

Under the condition that the storage bin has material and the discharge gate is not open, it is strictly forbidden to reverse the feeder. Otherwise, it may damage the spiral blades and even burn the motor.

-

If the user does not have packaging equipment from our company, it is necessary to install an overcurrent protector in the motor control section of the feeder to prevent motor burnout from excessive current, unless using our company's recommended packaging equipment

-

Perform a comprehensive inspection of the equipment every three months to check for wear, looseness, and other mechanical components.

-

If the machine needs to be stopped for an extended period, it must be thoroughly cleaned, and the main power supply should be disconnected. When restarting, conduct an electrical inspection before powering on.

Write your own review

Also Offers

Big Promotions

Containment Automatic Capsule Filling Machine SFK-703

Call for Quote

Fully Automatic Dosator Capsule Filling Machine CZ-40

Call for Quote

Related products

Powder Sifter Machine SY Series

$849.00

Powder Sifter Machine CXZ-Series

Call for Quote

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche