Induction Seal VS Heat Seal: Which is the Better Choice?

Are you struggling with which sealing method to use? An induction seal or a heat seal? I guess it's not an easy choice to make, as it can ultimately have a significant impact on your product quality.

Induction seals and heat seals are the most common sealing tools. Yet, there are many differences between them. To end up with a more informed choice, we’d better start by figuring out what exactly these two seals are. Let's dive right in!

What is an Induction Seal?

An induction seal is a durable and effective container closure produced by an induction sealer.

Well, what is induction sealing? Induction sealing is a non-contact process. It primarily uses the heat generated by an electromagnetic field to seal containers. The liner with the conductive material melts under the heat and then solidifies at the mouth of the container, which creates a perfect induction seal.

Well, what is induction sealing? Induction sealing is a non-contact process. It primarily uses the heat generated by an electromagnetic field to seal containers. The liner with the conductive material melts under the heat and then solidifies at the mouth of the container, which creates a perfect induction seal.

What is a Heat Seal?

You may often see heat seals on snack bags in the supermarket. Most of them are produced by a heat sealing machine.

The heat sealer generates high temperatures that heat up the materials ready to be sealed, and then the two materials will bond together to form a strong seal. Unlike induction sealing, heat sealing is a process that directly touches the material.

Benefits of Using an Induction Seal

Using induction seals is the most popular sealing method today. Here are some of the benefits it can bring:

- Induction seals can be used as tamper-evident markings. These seals are not easily removed. Once the induction seal on the container is broken, the product has probably been tampered with. So, induction seals ensure that customers can use the product with confidence.

- Induction seals can also effectively avoid product leakage.

- The use of induction seals helps to keep products fresh and extend their shelf life.

Benefits of Using a Heat Seal

- The heat seal is a widely used sealing method. You can apply it to products like food, pharmaceuticals, and cosmetics as you wish.

- Like induction seals, heat seals can also provide tamper-evident closures for products.

- Finally, using heat seal is also cost-effective. Compared to other sophisticated packaging tools, the process of a heat seal is relatively simple and therefore cheaper to use.

Disadvantages of Induction Sealing

Knowing the drawbacks of each sealing technique is also helpful for you to make an informed choice. Here are a few of the disadvantages of induction sealing.

- The induction sealing process requires the use of specific materials. Because the electromagnetic field plays a major role in induction sealing, there must be a conductive material in the cap for the induction seal to work. Without the conductive material, the induction seal will most likely fail.

- Induction sealers are more costly than heat sealing equipment. Also, mass induction sealing operations consume large quantities of conductive material, which increases the cost.

- Induction sealing cannot handle containers of any shape and size.If you are trying to seal an oddly shaped or oversized container, an induction sealer might not be able to help you.

Disadvantages of Heat Sealing

When using a heat sealer, you may find some troubling shortcomings. They include:

- Like induction sealing, heat sealing has restrictions on materials. The heat sealer is normally only used to seal materials that can be melted under heat, such as plastics. If unsuitable materials are used, heat seals can be much less effective.

- Another limitation of heat sealing is that it has specific temperature requirements. When using a heat sealer, you need to pay special attention to the temperature control. When the temperature is set too low, the seal may not work. On the contrary, a high temperature may cause the material to burn.

- Heat sealing technology creates a closure that can easily be punctured or torn. So, this can be a problem for products that need strong protection.

Induction Seal VS Heat Seal: What Are the Real Differences?

Working Principle

Induction sealing makes use of electromagnetic induction to seal containers. When the container is under the induction head, the machine generates an electromagnetic field. This transfers an electric current to the liner in the cap, which has a conductive material. The liner then heats up quickly and melts. Once cooled, the liner forms a seal at the container's mouth.

Heat sealing, on the other hand, uses direct heat to melt the materials on the pouch, bonding them together to form a seal.

Safety

Induction sealing is a non-contact process. It primarily uses electrical current to seal containers. Therefore, using induction sealing is very safe in most cases.

In comparison, heat sealing is not that safe. Because it usually involves demanding temperature control. Then, the operator is likely to get injured if the temperature is set too high by mistake.

Applications

In the food & beverage industry, induction seals are commonly used to seal containers with liquid products. In the pharmaceutical industry, they can be used to seal vials and syringes. More importantly, induction sealing can provide tamper-evident closure, which enhances the safety of products.

Similar to induction sealing, heat sealing can also be applied in the food and medical industries. The difference is that the containers it seals are mostly bags. Materials that heat seals can handle include plastics, films and aluminum foils.

Induction Sealers and Heat Sealers: From ipharmachine

LGYF-2000 Continuous Induction Sealing Machine

LGYF-2000 is a continuous induction sealing machine manufactured by ipharmachine. This machine is the culmination of our company's years of experience and technological improvements. It can seal all kinds of containers perfectly and quickly. This automatic induction sealer is also one of our most popular machines.

Below are the technical specifications of the induction sealer:

|

Model |

LGYF-2000 |

|

voltage |

220V/110V 50/60HZ |

|

Power |

1.5KW |

|

Capacity |

0-12m/min |

|

Sealing diameter |

20-130mm |

|

Suitable height of bottles |

40-400mm |

|

Weight |

72kg |

|

Dimensions |

1550x600x400mm |

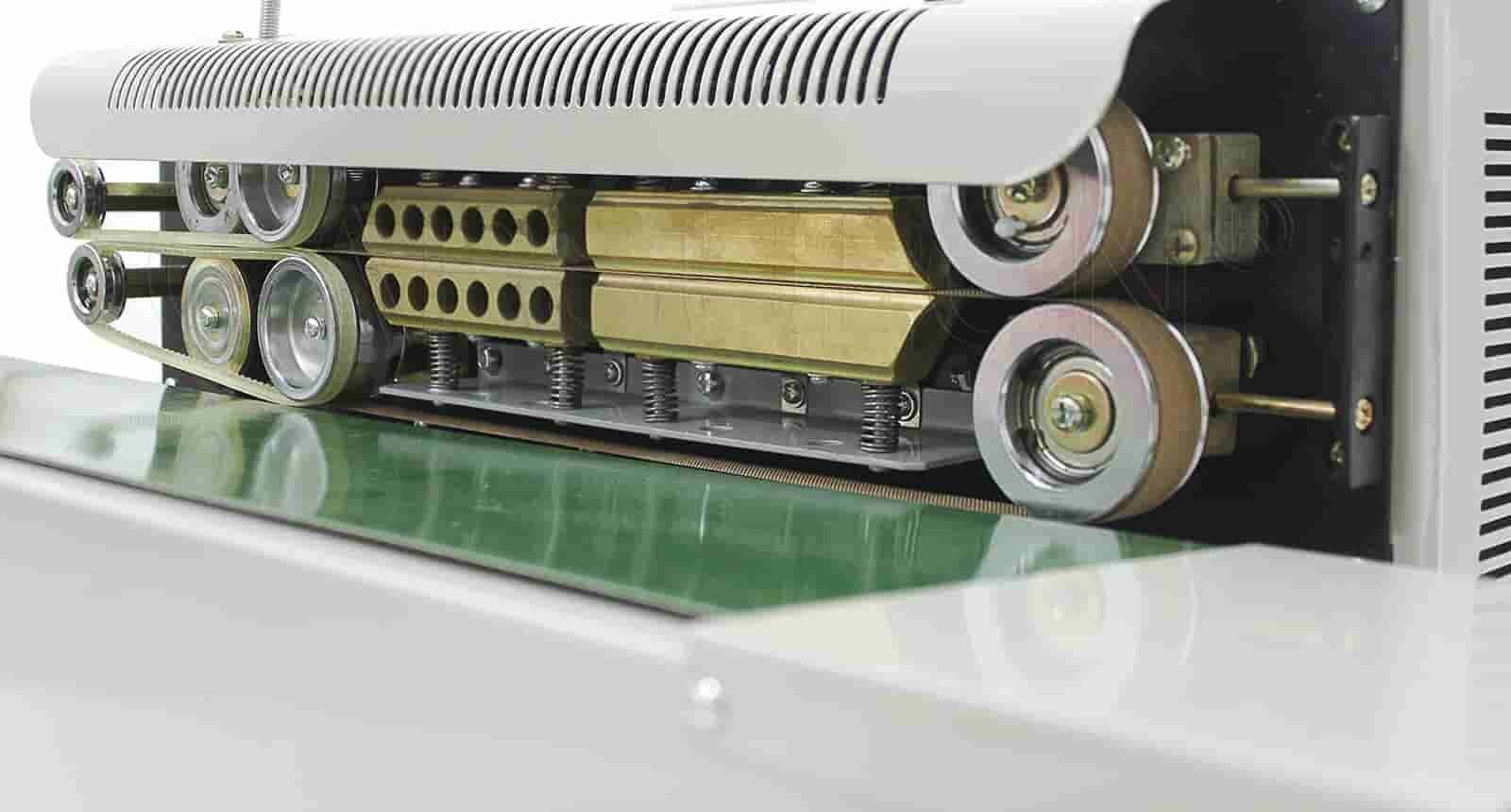

CFR-900 Continuous Heat Sealer For Plastic Bag

Developed by ipharmachine, this heat sealer is a high-performance and flexible machine. Its sealing speed and temperature can be adjusted according to the material thickness, which guarantees the sealing quality.

Check out the technical specifications of this heat sealer:

|

Model |

CFR-900 |

|

Sealing Width |

6mm-14mm |

|

Sealing Length |

0~Limitless |

|

Film Thickness |

0.03-0.8mm |

|

Printing Words Number |

39 |

|

Sealing Speed |

Max. 12meters/min |

|

Temperature Range |

0~300°c |

|

Power |

600W |

|

Voltage |

220V 50HZ/110V 60HZ |

Final Takeaway

At the end of the day, how you choose the best sealing method depends entirely on your business needs. There are pros and cons to both induction sealing and heat sealing. For some tasks, one is appropriate, while for others, the other is the right choice. All the information above will help you choose the right sealing machine.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche