Induction Sealing Machine Working Principles and Applications

Are you looking for an effective way to seal a pill bottle? Perhaps an induction sealer could meet your needs. It is a versatile device that helps you seal your bottle perfectly. At the same time, it can also effectively protect the medicine in the bottle, protecting it from leaking and tampering.

Well, before buying an induction sealer, knowing some relevant information can help you make a better choice. This information include what is an induction sealer? How does an induction sealer work? What industries can this machine be used in?

This guide will explain in detail how induction sealers work and their applications. With this knowledge, you will find the induction sealer that works best for your business.

How Does an Induction Sealer Work?

An induction sealer is a device that seals containers with induction heating. There are several types of induction sealers in the market, from manual to fully automatic. However, they work on the same basic principle.

The seal created by an induction sealer may look like just a thin silver disk. However, its internal structure is more complicated than it looks. Normally, an induction seal consists of three layers:

- The backing layer

- The foil liner layer

- The heat seal layer

How do these layers work with the induction sealer to create a perfect seal?

First, when the bottle passes through the induction sealing head, the induction sealing machine generates an electromagnetic field.

The electric current produced by the electromagnetic field transmits to the foil liner layer, which rapidly heats up the liner. This process is known as induction heating.

When the temperature of the foil layer rises, so does the heat sealing layer. Such high temperatures will cause the heat seal layer to start melting.

The bottle then leaves the induction sealing head. Once the heat seal layer cools and solidifies, it firmly sticks to the mouth of the container, creating a long-lasting cap seal.

How does a manual induction sealer work?

After understanding the basic working principle of induction sealing machines, you may wonder how different types of induction sealers apply this principle in practice. For starters, let's check out the video below to find out how a manual induction sealer works.

Step 1: Before you officially start using the manual induction sealer, you need to make sure that the foil liner inside the cap is intact.

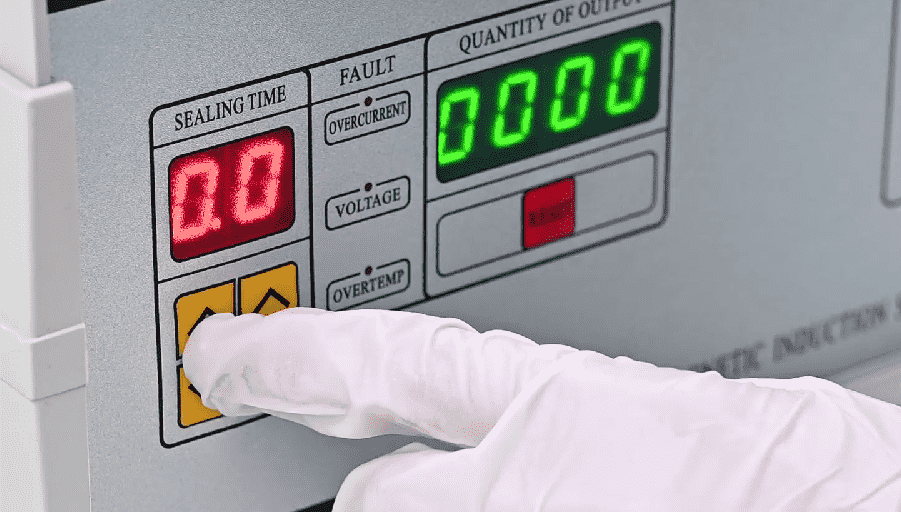

Step 2: Next, you should place the bottle on a stable tabletop and turn on the machine's power switch.

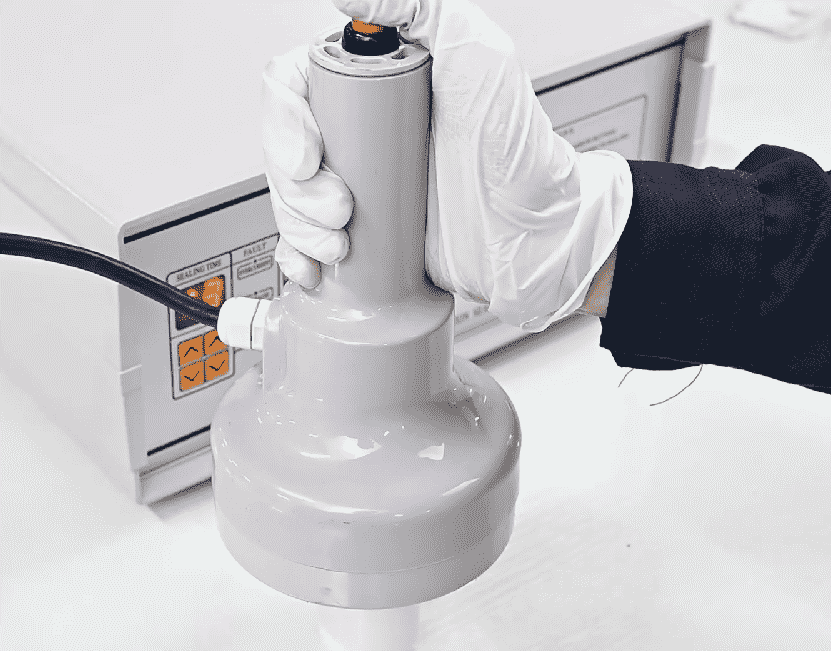

Step 3: Pick up the induction head, snap it firmly onto the bottle cap, and then press the start button. At this point, the machine will generate an electromagnetic field to seal the bottle. Once the seal is done, you can release the cap and take away the induction head.

Step 4: Checking the final seal is also an important step. You can gently press the bottle's sealing layer with your finger to make sure it is intact and firm.

How does an automatic induction sealer work?

Compared to manual induction sealers, automatic induction sealing machines are much more efficient. An automatic induction sealer can handle hundreds or thousands of containers in a minute. Alright, let's find out how this amazing machine works by watching the video below.

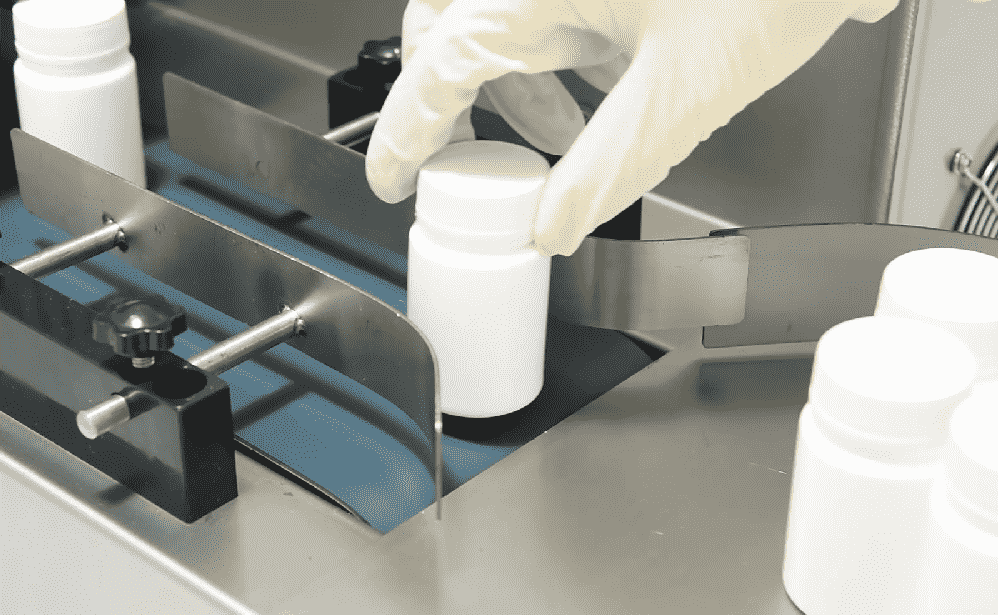

Step 1: First, you need to place the capped bottle on the conveyor belt of the automatic induction sealer.

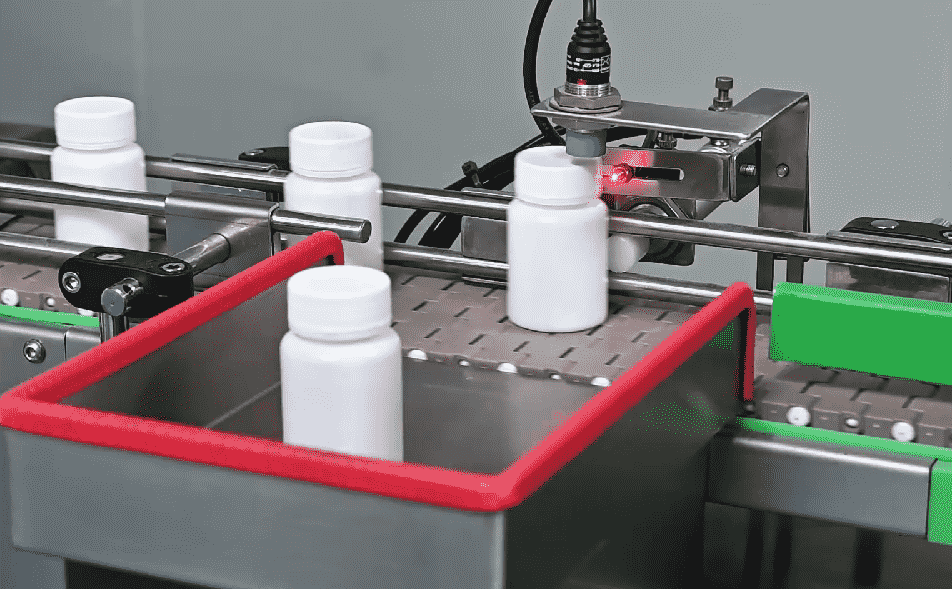

Step 2: Next, as the conveyor moves, the bottles go through the sorting system first. If the sensors detect that the foil liner in the cap is incomplete, or that the bottle is not properly capped. The bottle will be removed from the conveyor belt and goes to the reject station.

Step 3: When the compliant bottle enters the sealing head, the machine generates a high-frequency electromagnetic field. The current from the electromagnetic field then heats the aluminum foil liner in the cap, causing its heat sealing layer to melt.

Step 4: Once the bottle leaves the sealing head, the heat sealing layer will quickly cool down and solidify. It then adheres solidly to the bottle's mouth. In this way, a firm and long-lasting seal is created on the container.

Step 5: When the bottle is sealed, the sensor that comes with the induction sealer will detect the integrity of the seal. With it, you can be sure that the final product you sell is perfectly sealed.

Step 6: On a pharmaceutical production line, an automatic induction sealer doesn't stand alone. It usually connects to other production equipment. So, once the bottle has been successfully sealed, it will leave the induction sealer along the conveyor belt for subsequent labeling or other packaging stations.

Hot Applications for Induction Sealing Machines

After learning how an induction sealer works, you should believe that it is a very effective packaging device. So, are you wondering what are the top applications for it? Let's find out.

Pharmaceutical Industry

In the pharmaceutical industry, we often see a wide range of medicine bottles. However, you probably didn't realize that most of these bottles are sealed by induction sealers. The most common pill bottles include:

- Capsule Bottles

- Tablet Bottles

- Syrups

Food and Beverage Industry

A good seal contributes a lot to keeping food and beverages fresh. Induction sealing machines are just the ideal equipment for this purpose. Let's take a look at the hot foods you can seal with induction sealers:

- Ketchup

- Mustard

- Mayonnaise

- Vinegar

- Milk

- Fruit Juices

Cosmetic Industry

Induction sealers also seal various cosmetic and personal care products. These products include

- Body washes

- Shampoos

- Skin lotions

- Creams

Chemical Industry

Induction sealers can provide efficient sealing solutions for chemical containers. Common products include:

- Lubricants

- Paints

The Bottom Line

I hope you already have a deep understanding of induction sealing machines by reading this guide. If you are interested in this efficient machine, please feel free to contact ipharmachine.

With ipharmachine, you can get the best quality induction sealing machines. We have a range of induction sealing machines for all your needs.

Our machines are available in a wide range of sizes and powers, so you can use them to seal different kinds of containers effortlessly. Also, they provide a fast and consistent seal, which ensures the integrity and freshness of your products.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche