Understanding the Induction Sealing Process

Most newcomers in the packaging world might think that capping has provided a secure seal for the packaged product. However, if you want the content inside the container to have a longer shelf life, induction sealing is an essential step that should not be overlooked. Induction sealing can offer double security for products packaged in bottles or jars. In this article, we will delve into the concept of the induction sealing process and why we need it. Without further ado, let's dive right in!

What is an Induction Seal?

Can you guess what the key component of the induction sealing process is? That's right. It's an induction seal liner. This liner is also known as a heat induction seal. It is typically made of a foil laminate. This multi-layered material is initially placed inside a cap. After the induction sealing process, the liner is removed from the cap by layers or entirely to form a bond with the lip of the container. The bond acts as a hermetic seal, protecting the product inside the container against external factors.

Induction seal liners are often available in two constructions. They are:

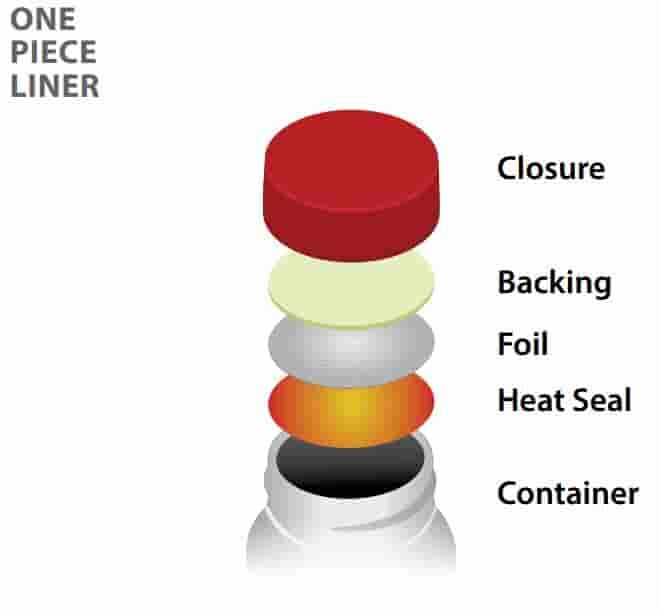

1. One-piece liners

A one-piece induction seal liner comes in a foam-backed or paper-backed foil laminate. This type of liner is usually composed of a backing layer, a foil layer, and a heat seal layer. It's inserted into the closure. By using an induction sealer, the one-piece liner provides a complete, airtight seal on the lip of the container.

(Image Source: Enercon Asia Pacific)

After induction sealing, the liner is entirely removed from the closure, suitable for products that do not require a reseal. Some one-piece liners include a pull tab or half-moon tab for easy peeling. Lift and peel liners are typical examples of one-piece induction seal liners.

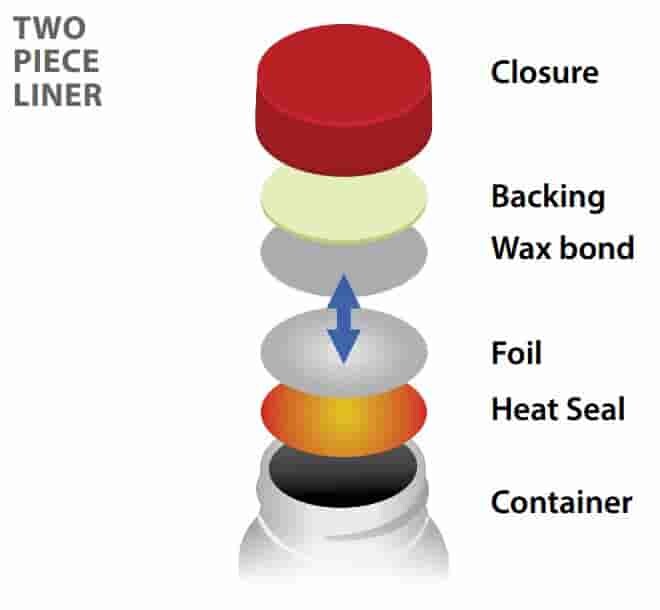

2. Two-piece liners

A two-piece induction seal liner is made with a backing layer, a wax layer, a foil layer, and a heat seal layer. This liner is glued into the closure. During induction sealing, the liner splits into two pieces. When heating, the wax layer between the pulpboard backing and foil is melted and absorbed into the backing. This makes the pulpboard retained inside the closure. The removed foil and heat seal form an induction seal on the container lip.

(Image Source: Enercon Asia Pacific)

What is Induction Sealing?

Induction sealing is one of the essential packaging technologies widely used in various industries today. It's a non-contact heating process that takes place following filling and capping. As the name suggests, the induction sealing process takes advantage of electromagnetic induction to perform the sealing operation. This kind of heat sealing process utilizes an induction seal liner, which is an aluminum foil laminate, to create a hermetic, tamper-evident, and leak-proof seal on the lip of a plastic or glass container.

How Does the Induction Sealing Process Work?

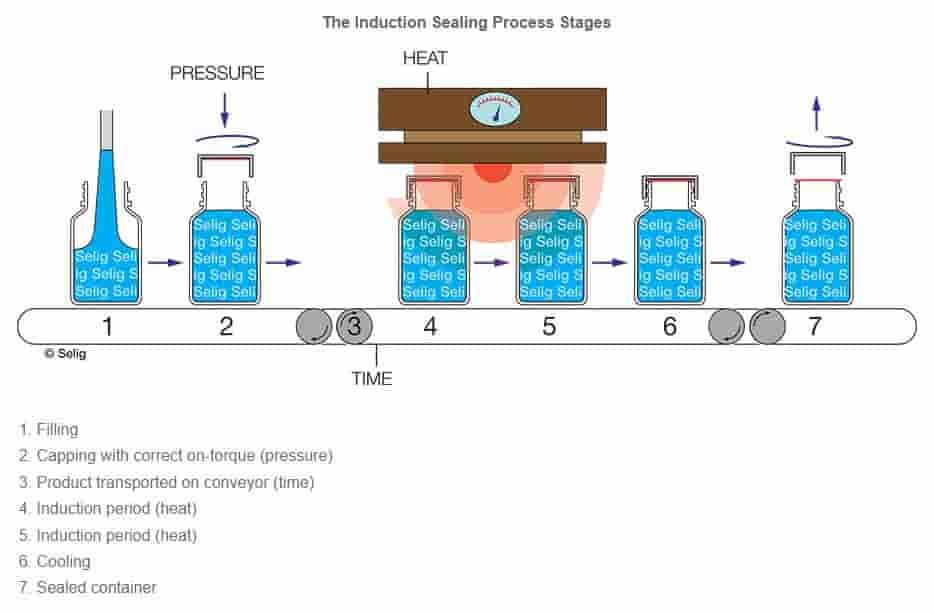

To put it in simple terms, the induction sealing process works by using electromagnetic induction to hermetically seal a container. During the process, the container is placed in an electromagnetic field where an eddy current is induced to heat the foil laminate and bone it to the lip of the container.

(Image Source: Selig)

The induction sealing process can be done using a handheld device or an automatic sealer. Here, we break down the induction sealing operation in an induction sealer into the following key steps.

STEP 1: Set the induction sealing parameters such as power levels, sealing time, conveyor speed, and other relevant settings.

STEP 2: Ensure the induction liners are compatible with the container and closure.

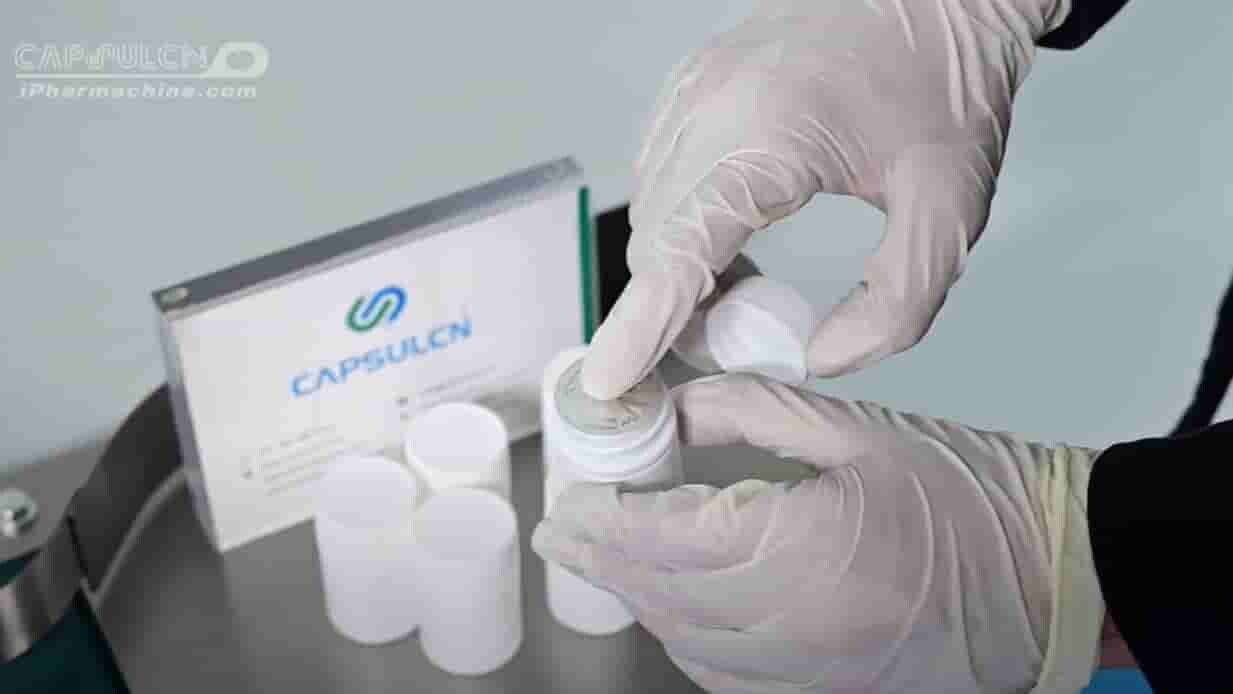

STEP 3: Insert the induction seal liner into the closure and place the closure onto the container.

STEP 4: Load the containers onto the conveyor, ensuring they're center aligned with the mark labeled on the sealing area.

STEP 5: Enable the conveyor to guide the containers to properly pass underneath the induction sealing area.

STEP 6: The sealing area generates an electromagnetic field to heat the induction liners.

STEP 7: If a two-piece liner is used, the heated foil laminate causes the wax layer to melt and be absorbed into the foam or pulpboard backing while bonding the polymer layer (heat seal layer) to the container lip. The liner splits into two parts. If a single-piece liner is used, the heated foil causes the polymer to melt and attach to the land area of the container. Finally, a hermetic seal is created.

What are the Benefits of Induction Sealing?

Why is the induction sealing method so popular among the food and beverage, pharmaceutical, nutraceutical, and chemical sectors? Here are some key advantages of the induction sealing process.

Tamper Evidence

Ever notice that little foil cap when you open a new jar of peanut butter? That's the magic of induction sealing, shouting "tamper evidence!" When the seal is intact, you're guaranteed that the product hasn't been messed with. It's like a security guard for your goodies.

Freshness Preservation

Picture this: your favorite cookies taste as scrumptious as the day they were baked. Induction sealing makes it happen by creating an airtight fortress around your snacks, shielding them from moisture and oxygen.

Leak Prevention

Leaky containers? Not on induction sealing's watch. Whether it's saucy or syrupy, this sealing superhero ensures your liquids stay put. No more messy spills to deal with during transport or storage.

Versatility

Plastic, glass, metal – induction sealing isn't picky. It plays nice with all container materials. So whether your product comes in a plastic bottle or a fancy glass jar, induction sealing is up for the task.

Adaptability to Product Varieties

Different sizes, shapes, or closure types? No problem! Induction sealing is like a chameleon, adapting to the unique needs of your products. Big or small, it's got the perfect seal for them all.

Reduced Product Evaporation

Ever notice how some liquids mysteriously vanish from their containers? Induction sealing puts an end to that. It locks in the goodness, making sure your liquids stay at the right concentration without any sneaky disappearing acts.

Environmentally Friendly

Induction sealing is not just a hero for your products; it's kind to the planet, too. By skipping the need for extra materials like adhesives or heat-activated liners, it's a green sidekick in the world of packaging.

Efficiency and Speed

In the world of packaging, time is money. Induction sealing is like The Flash of the packaging line – fast, efficient, and getting the job done in a blink. High-speed production? No sweat!

Cost-Effective

While there might be a setup cost for the induction sealing equipment, think of it as an investment. The efficiency, reduction in product waste, and extended shelf life add up to savings in the long run.

How iPharMachine Can Help With Your Induction Sealing Needs

If you're looking for effective solutions to your packaging business, iPharMachine is here to help! Whatever product you're packaging, we offer you a wide range of induction sealing solutions. Our dedicated team is on standby to communicate with you via phone or online chat. Contact us today to learn more about how the induction sealing process can benefit your business.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche