Industrial Blender vs Mixer: Which One Fits Your Needs?

In food processing, pharmaceuticals, chemicals, and cosmetics industries, "blending" and "mixing" are two commonly used terms. They are often confused with each other and considered as the same process. However, technically, there are slight differences between them.

To understand the difference in a more intuitive way, let's take a look at the specific equipment made for these processes: blender and mixer. If you're going to add such a piece of processing equipment to your facility, keep reading. You'll learn their types, advantages, limitations, and applications to make an informed buying decision.

What Are Industrial Blenders?

Industrial blenders are machines used to blend and homogenize large volumes of materials. Popular among various industries, they can combine solid particles or mix bulk solids with small amounts of liquid. Notably, the blending process is relatively gentle.

An industrial blender handles sizable batches, ensuring consistent quality and texture of the final product. That's why it's ideal equipment for processing food items, chemicals, cosmetics, or pharmaceuticals.

Types of Industrial Blenders

While an industrial blender is a good helper, it's not one-size-fits-all. It comes in a variety of styles. Each is suited for specific material characteristics and applications. The most common types include:

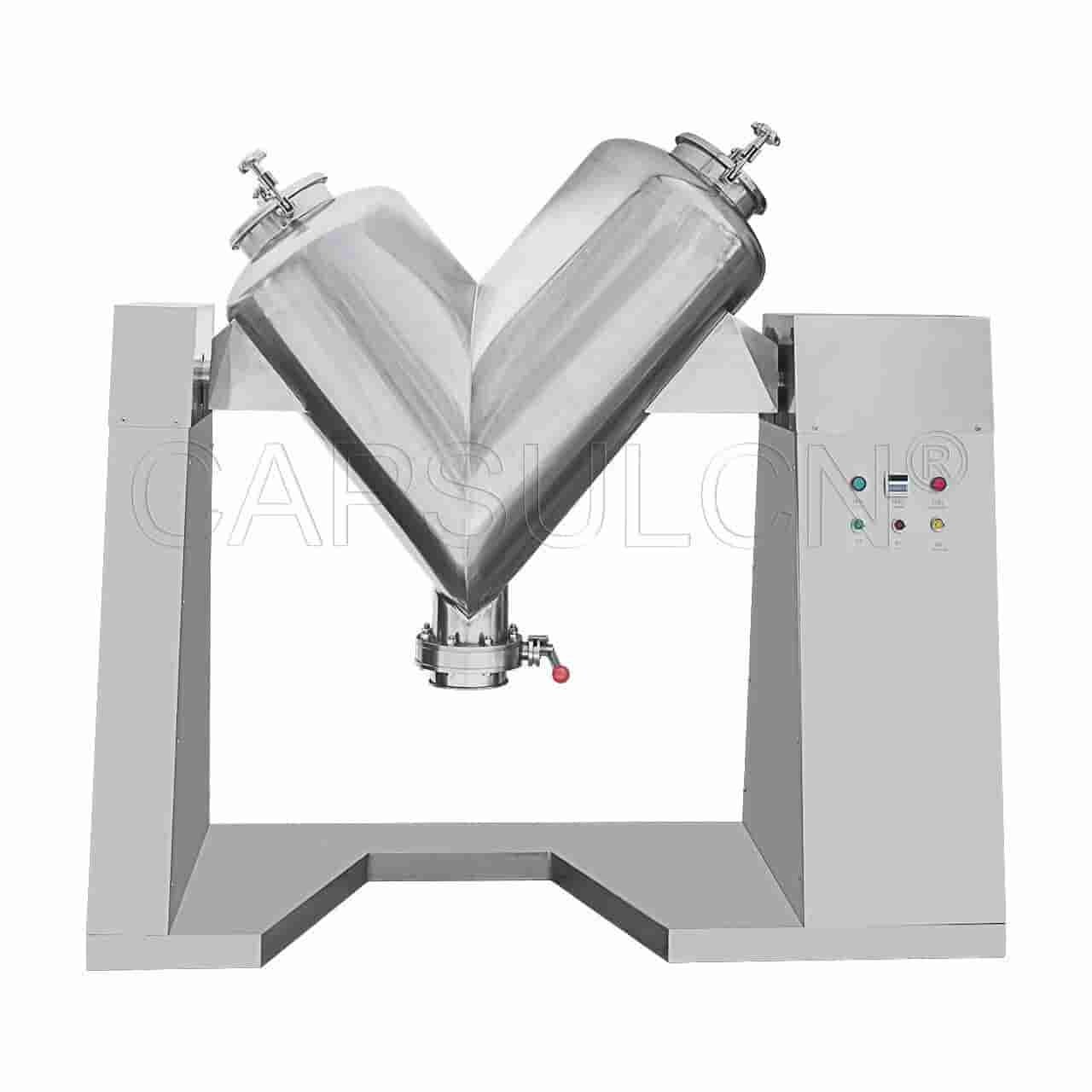

1. V Blender

V blenders are a kind of tumble blender. V blenders have two hollow cylindrical shells connecting at an angle, forming a V shape. It is for this design that they may be referred to as Twin Shell or V-cone blenders.

V blenders are ideal for gentle blending. The good thing about them is that they dry mix well, but they do not have a huge shearing force. So, for processing very fine powders or granules, they're not the best choice. These V blenders rotate around a central shaft to tumble the materials inside.

2. Double Cone Blender

Another member of the tumble blender family is the double cone blender. They have two cones welded with a cylindrical part in the middle.

Double cone blenders, like V blenders, rotate around a central shaft. Materials move back and forth between the two cones as the blender rotates. Double cone blenders are great for materials that need to be gently tumbled rather than need to be stirred vigorously. They can revolve 360 degrees to blend the materials completely.

3. Ribbon Blender

Ribbon blenders have a U-shaped horizontal trough with a central agitator. Its agitator includes inner and outer helical ribbons. In mixing the materials, these ribbons rotate in opposite directions. These blenders come with a wide-open top for ease of loading products.

Ribbon blenders are a good option when you need to handle large volumes of materials. They are also perfect for dry and wet mixing. If you have delicate products that need to be mixed in large quantities, then the ribbon blender is great because it can mix at a low speed.

Advantages and Limitations of Using Industrial Blenders

Advantages

- Uniform Mixing: One of the key strengths of blender operation is in mixing dry substances together and creating a uniform mixture with an even distribution of all components.

- Different Designs: Another benefit of blenders is that there are a lot of blender varieties available on the market, with each suited to specific needs.

- Performance: They are more efficient at fully blending free-flowing powder and granulate materials.

- Size: Industrial blenders are a great way to mix very large amounts, which helps a lot during mass production processes.

Limitations

- Material Limitations: Sticky and vicious materials are difficult to blend with blenders. They can't work well with pastes or slurries.

- Shear Sensitivity: The level of shear that industrial blenders can apply is limited, so they cannot mix well material that needs to be processed with strong mechanical force.

- Non-Uniform Mixing: When there is a great difference in the physical characteristics of materials, such as size or density, blenders may cause non-uniform mixing.

- Scalability Issue: Industrial blenders manage high quantities well, but scaling down to smaller batches may decrease their mixing efficiency.

What Are Industrial Mixers?

Industrial mixers are machines used to combine multiple ingredients into a homogeneous mixture. Unlike blenders, mixers often incorporate more vigorous and diverse mixing actions. They combine materials by beating or stirring them.

Industrial mixers can handle liquids and semi-solids. The mixers usually feature speed control for more precise material processing. They can also be jacketed with temperature control to handle specific mixing tasks.

Types of Industrial Mixers

Industrial mixers come in various designs to cater to different mixing needs. Among the most widely used varieties include:

1. High-Shear Mixer

High-shear mixers are designed for rapid mixing, emulsification, and homogenization. They're perfect for handling materials requiring a fine and quick combination. These mixers are capable of breaking down solids and mixing them into liquids in no time.

High-shear mixers feature a high-speed rotor and stator. This configuration can generate strong shear forces that break down particles and disperse them evenly throughout the mixture. They are also ideal for processing viscous or semi-solid materials.

2. Planetary Mixer

Planetary mixers feature a blade that moves around the bowl just like a planet orbits the sun while also spinning on its own. This unique working way ensures everything gets thoroughly mixed.

The mixers are perfect for handling creams, ointments, or other semi-solid formulations. You'll find planetary mixers in the food industry for tasks like making dough, pastries, and confectioneries and in the pharmaceutical and cosmetics industries for creams and lotions.

3. Static Mixer

Static mixers are devices for continuously mixing substances. They are typically used to mix liquids and gas streams in pipeline systems. Unlike other mixers, static mixers don't have any moving parts. This means the mixing action is not performed by rotating blades.

Instead, they use a series of fixed elements to create turbulence in the fluids, mixing them effectively. They can work for batch production with a recirculation line. Static mixers are super versatile and can mix any pumpable material, no matter how it flows.

Advantages and Limitations of Using Industrial Mixers

Advantages

- Versatility: Mixers can handle powders, liquids, slurries, and pastes. They can effectively combine materials of differing consistencies.

- Customization: There are many types of mixers. Each can come with customizable attachments for different applications.

- Intensive Mixing Capabilities: Mixers are better suited for applications requiring high shear, heat, or pressure. That is to say, they are ideal for for combining materials that do not naturally blend well.

- Application-Specific Designs: Mixers can be designed for specific processes like emulsification, homogenization, or wet milling, which go beyond simple blending.

Limitations

- Complexity and Cost: Industrial mixers can be more complex and costly than blenders. They often include customizable attachments, which can lead to higher maintenance and operation costs.

- Over-Mixing: The high shear forces applied by mixers may lead to over-mixing. This can damage the physical properties of some ingredients, especially those that are heat or shear-sensitive.

- Energy Consumption: Mixers generally consume more energy than blenders—for example, those designed for intensive mixing tasks like homogenizing.

- Batch Size Limitations: Similar to blenders, achieving optimal performance with very small or very large batches can be challenging.

Blender vs Mixer: What Are the Key Differences?

Looking to distinguish their features in a clear and concise way? Now, let's compare these two processing machines side by side.

|

Feature |

Industrial Blender |

Industrial Mixer |

|

Primary Use |

Mixing solids and semi-solids |

Mixing solids, liquids, semi-solids, and viscous materials |

|

Mixing Mechanism |

Gentle blending action |

Vigorous and diverse mixing actions |

|

Material Handling |

Ideal for free-flowing powders and granules |

Suitable for a wide range of consistencies |

|

Shear Force |

Low to moderate shear, not suitable for emulsification |

High shear capabilities, ideal for emulsification and homogenization |

|

Applications |

Food powders, pharmaceutical granules, chemical blends |

Food doughs, pharmaceutical emulsions, chemical dispersions |

|

Operational Scale |

Handles large volumes efficiently; not ideal for small batches |

Can be designed for both small and large batch operations |

Blender vs Mixer: Choosing the Right Equipment for Your Business

When deciding between an industrial blender and an industrial mixer, consider the following factors:

- Material Consistency: Figure out if your materials are mostly powders, granules, liquids, or thick, viscous substances.

- Production Volume: Think about how much material you need to process and pick equipment that can handle that amount efficiently.

- Mixing Requirements: Consider what kind of mixing your process needs. Blenders are great for gentle mixing, while mixers provide more vigorous and thorough blending.

- Space and Budget: Look at the space you have in your facility and how much you can spend on purchasing and maintaining the equipment.

- Industry Standards: Make sure the equipment complies with industry-specific standards and regulations for your application.

Blender vs Mixer: Industry-Specific Recommendations

Food Industry

- Blender: Ideal for dry ingredients like spices, flour, and sugar.

- Mixer: Suitable for dough, batters, and sauces.

Pharmaceuticals

- Blender: Used for blending powders and granules for tablets and capsules.

- Mixer: Essential for producing creams, ointments, and liquid formulations.

Chemical Industry

- Blender: Effective for mixing dry chemicals and powders.

- Mixer: Perfect for creating emulsions, dispersions, and solutions.

Cosmetics

- Blender: Suitable for blending powders for makeup products.

- Mixer: Ideal for lotions, creams, and gels.

FAQs About Blender vs Mixer

Q: Can I use a household blender or mixer for industrial purposes?

A: No, industrial equipment is built to handle heavy-duty processing and more intensive use. Misuse of household blenders and mixers for industrial applications can cause damage to the equipment.

Q: Can I use a blender for tasks that typically require a mixer?

A: You can, but it's not always ideal. Blenders are best for dry ingredients and light mixing tasks. If you need to mix something that requires more force or involves liquids, go for a mixer.

Q: Which is more energy-efficient: a blender or a mixer?

A: Blenders. Because they provide gentle mixing. Mixers consume more energy, especially when you use high-shear types.

Q: Are there specific applications where blenders are preferred over mixers and vice versa?

A: Definitely! If you're working in the food industry, use blenders to mix dry ingredients and mixers to make dough and batters. If in cosmetics and pharmaceuticals, choose blenders to mix powders and granules and mixers to handle creams and ointments.

Wrapping It Up

Knowing the differences between blenders and mixers can help you choose the right equipment for your business. If you were unsure where to start, we hope this blog post has cleared up any doubts you may have. Remember to consult with experts like iPharMachine - we provide a comprehensive range of raw material processing solutions to cater to all your needs.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche